Power cable strength testing machine with modular fixture

A power cable and combined fixture technology, applied in the direction of applying stable tension/pressure to test material strength, strength characteristics, measuring devices, etc., can solve problems such as hidden safety hazards, uneven quality of power cables, and endangering personnel safety. The effect of ensuring cable quality, improving stability and safety, avoiding deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

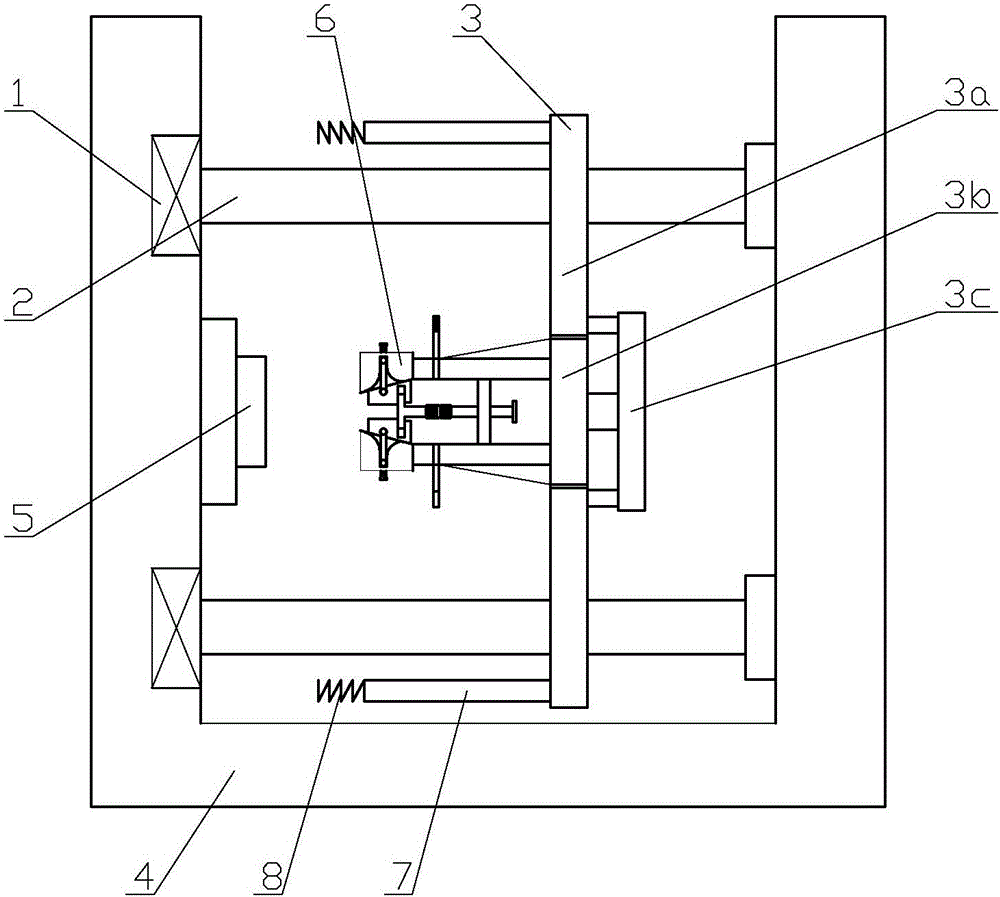

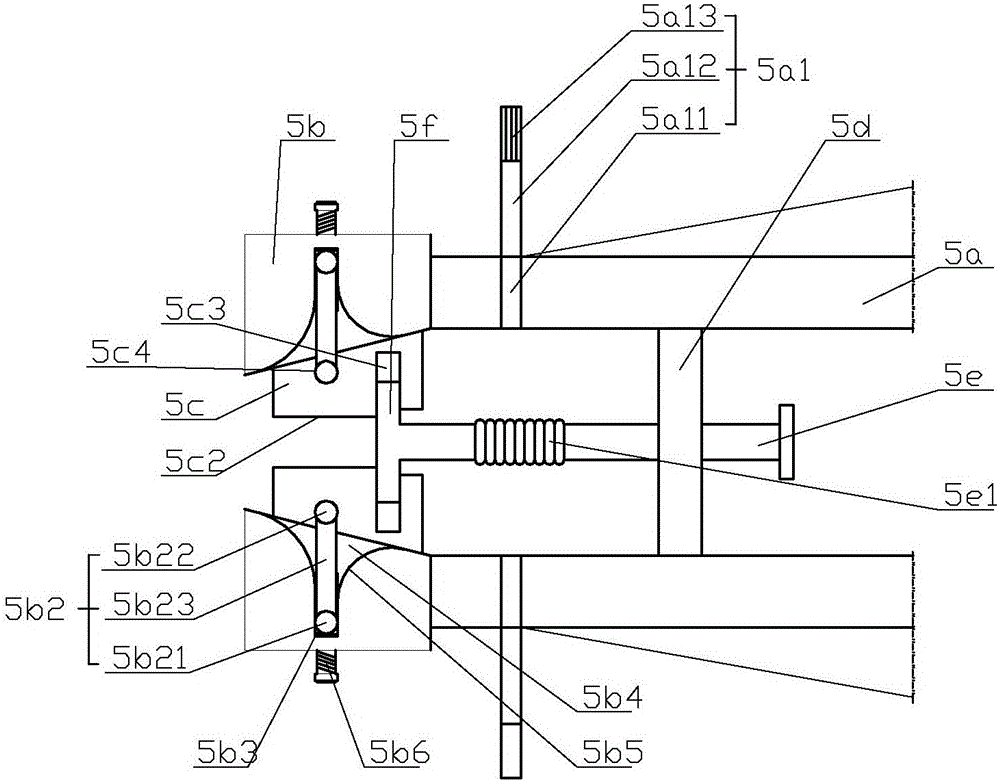

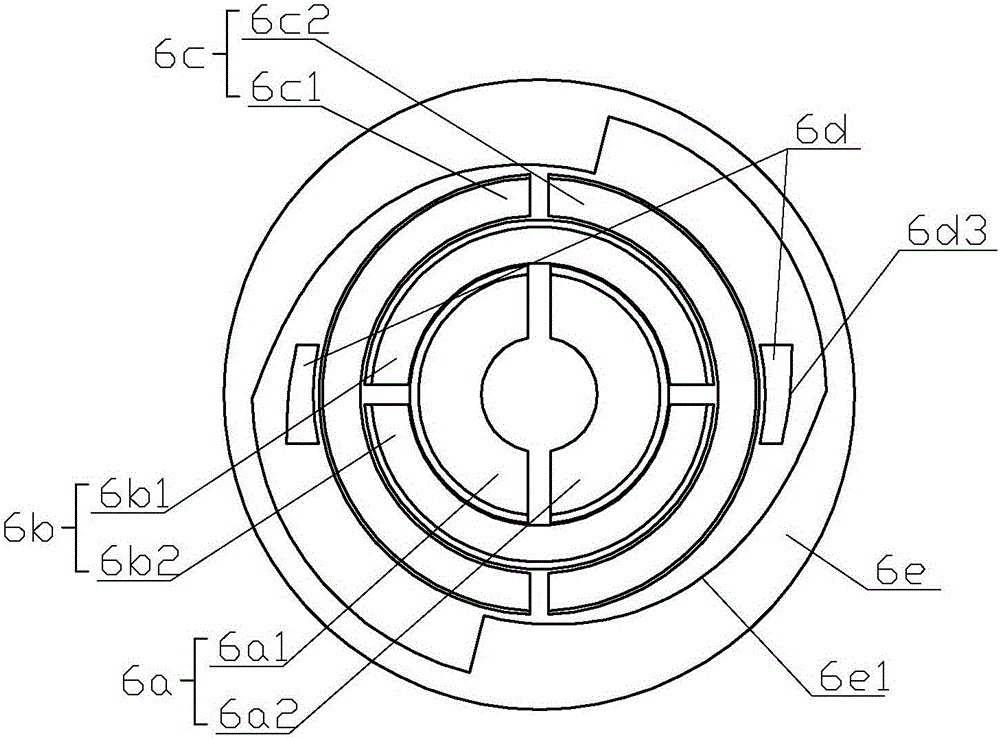

[0024] Such as Figure 1-8Shown is a specific embodiment of the power cable strength testing machine with combined clamps of the present invention. This embodiment comprises a servo motor 1, a transmission rod 2, a translation frame 3, a U-shaped frame 4, a gripper clamp 5 and a disk clamp 6, and a plurality of groups of symmetrical servo motors 1 are arranged on a side wall of the U-shaped frame 4, and the servo A transmission rod 2 is arranged on the motor 1, and the other end of the transmission rod 2 is rotatably arranged on the other side wall of the U-shaped frame 4, and a translation frame 3 is movable left and right on the transmission rod 2; the gripper clamp 5 is arranged on On the left surface of the translation frame 3, the disc clamp 6 is arranged on the U-shaped frame 4 corresponding to the position of the gripper clamp 5; the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com