Straight panel type bushing plate

A drilling template and straight plate technology, which is applied to the drilling template for workpieces and other directions, can solve problems such as structural defects, affecting workpiece clamping efficiency and fixture accuracy, fixture measurement, and inconvenience in inspection, so as to simplify assembly steps and ensure product quality. , the effect of shortening the assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

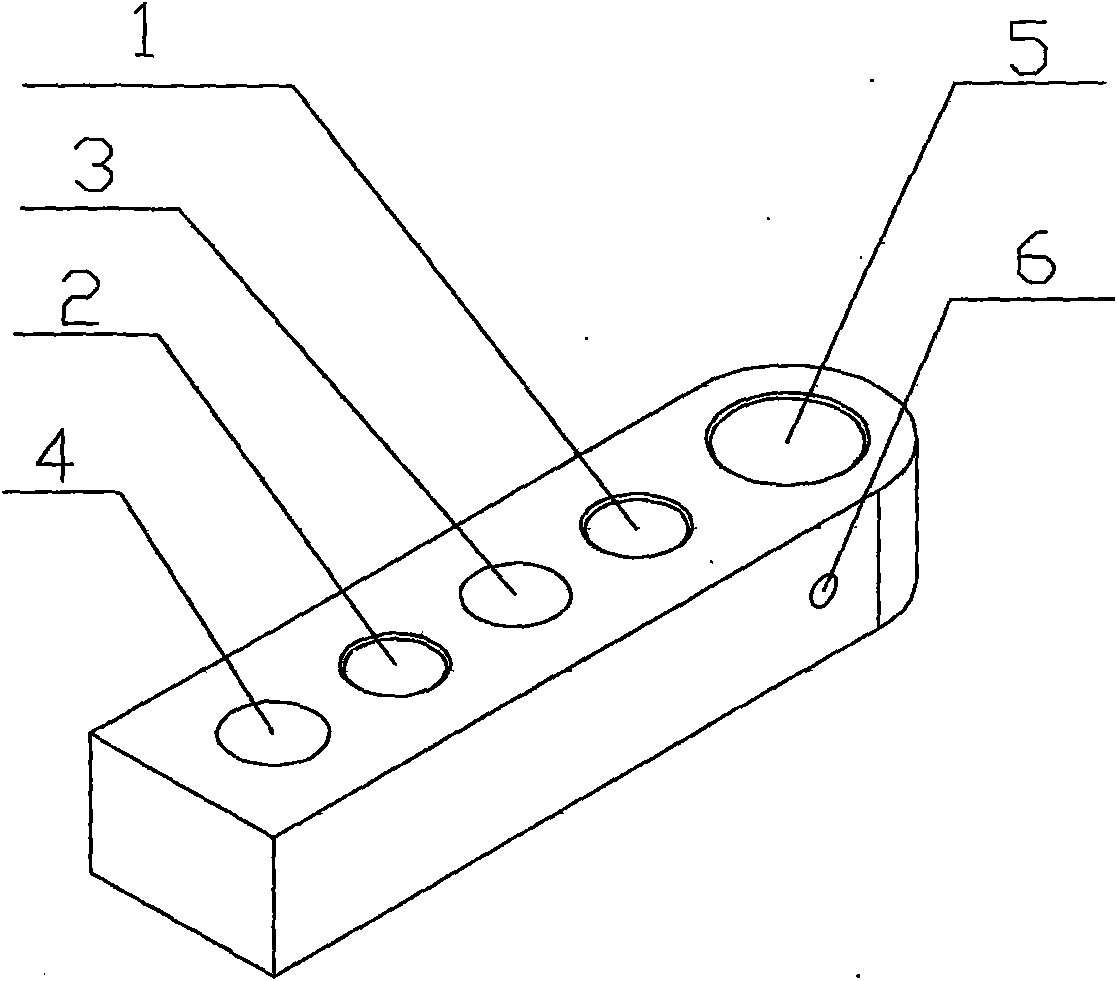

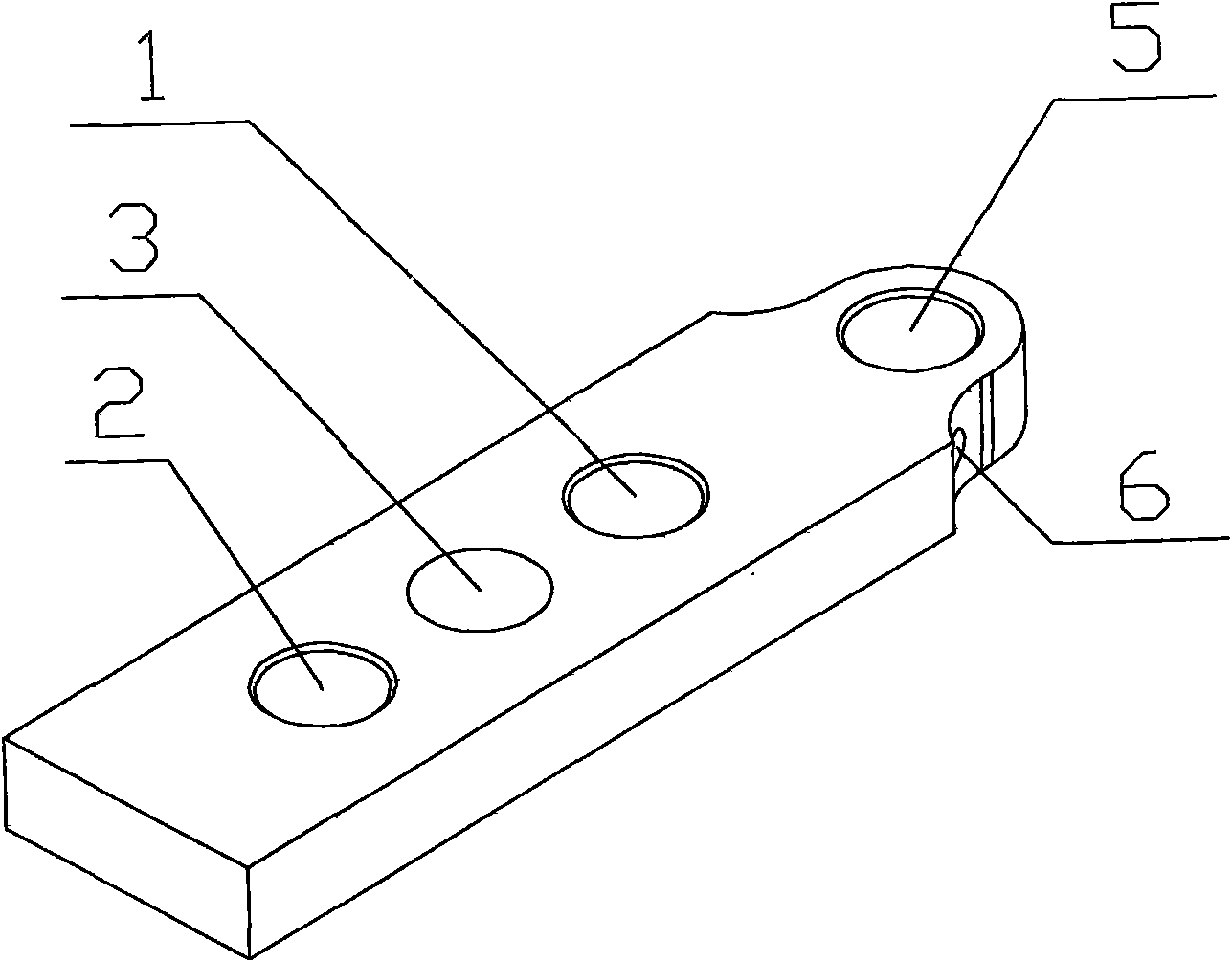

[0013] Straight plate drilling template, including template body, is characterized in that a guide hole is made at one end of the template body, and 2 positioning pin holes and 1 or 2 bolt holes are made on the template body. The arrangement of the two holes is from the guide hole Start as a dowel hole, a bolt through hole, a dowel hole, a bolt through hole, make a threaded hole perpendicular to the guide hole between the guide hole and the dowel hole, the threaded hole is tangent to the guide hole.

[0014] The guide hole is made into Φ12H7 or Φ18H7.

[0015] The positioning pin hole is made into Φ12H7, and the hole distance is 40±0.01mm.

[0016] The distance between the guide hole and the positioning pin hole is 25±0.01mm, 35±0.01mm or 55±0.01mm.

[0017] The bolt hole is made Φ13mm, the hole distance is 40±0.01mm, and the hole distance from the positioning pin hole is 20mm.

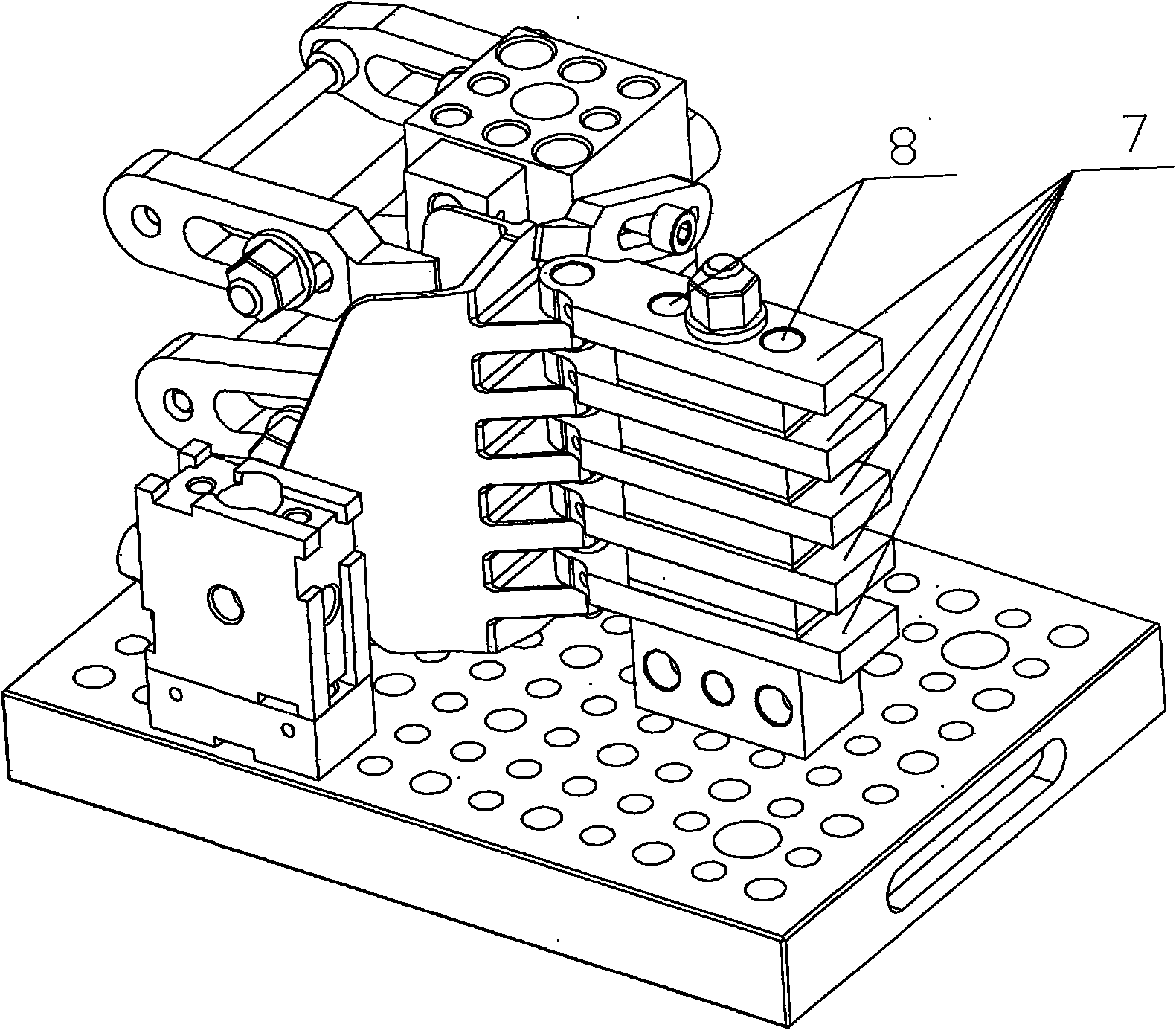

[0018] Application examples such as image 3 As shown, in order to make the holes of the lugs o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com