Modular fixture for microfluidic chip

A microfluidic chip, modular technology, applied in the field of biomedical detection, can solve the problems of not being able to withstand the pressure and speed of the liquid inlet, damage to the soft chip interface, limiting application and popularization, etc., to ensure effective use and monitoring The reliability, easy to carry, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

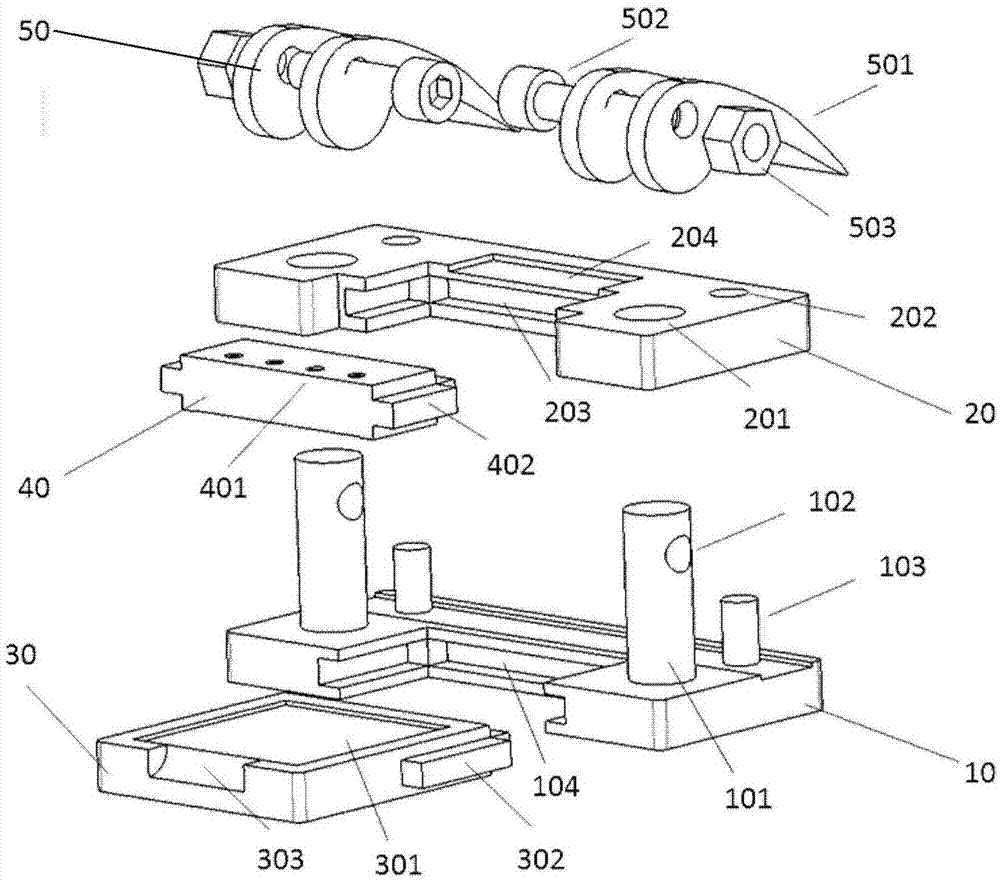

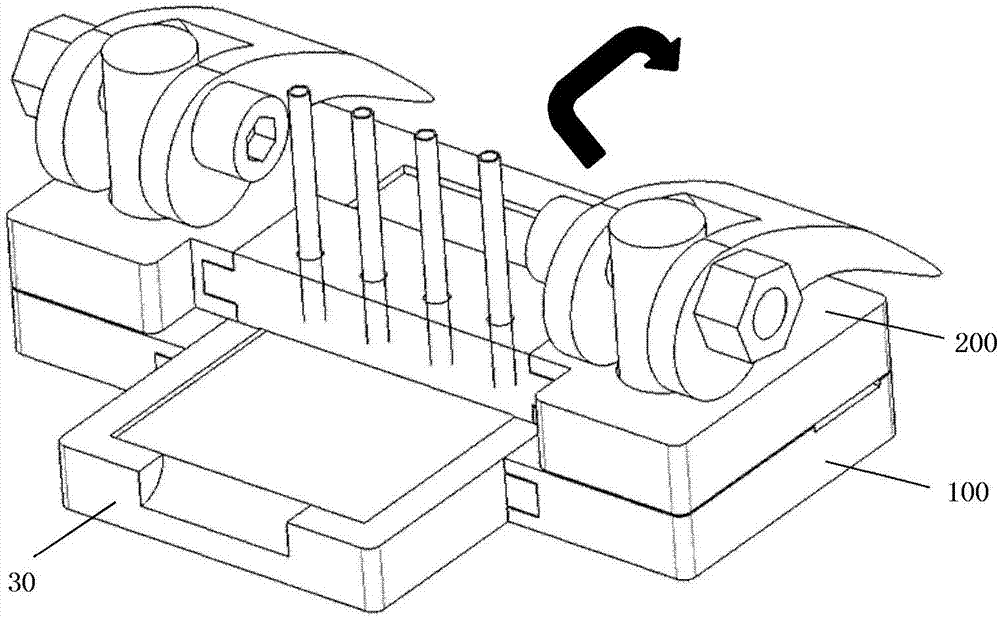

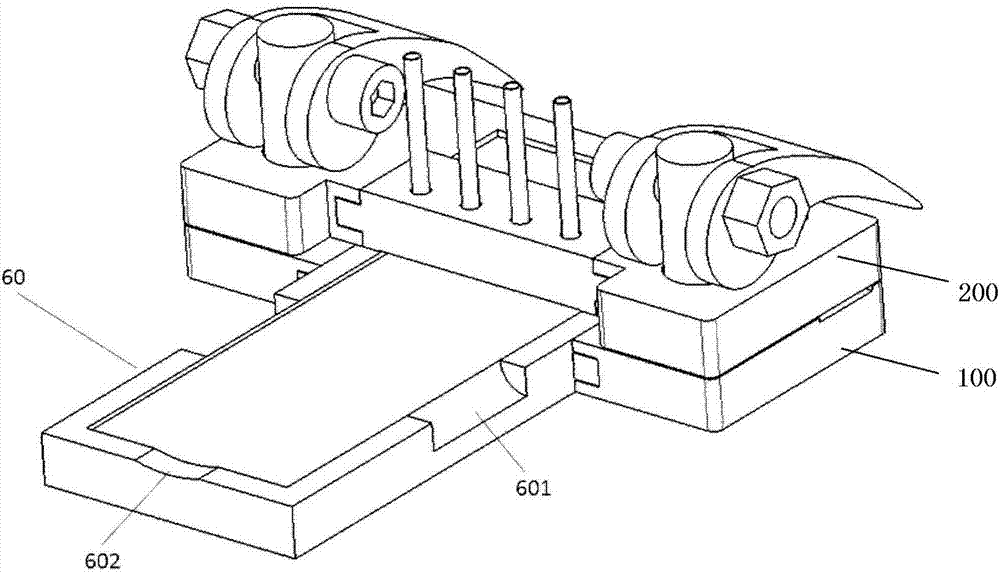

[0062] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. In the present invention, the terms "including" and "comprising" and their derivatives mean inclusion but not limitation.

[0063] The term "detachable connection" in the present invention means that two parts can be connected as a whole, or one part can be detached from the other after being connected as a whole. The detachable connection can be pin joint, tenon joint Connection, insertion or hoop connection, the present invention is not limited thereto. It is preferable to adopt a connection method that can be detached by hand (without using additional tools), such as plug joint or mortise joint.

[0064]In this specification, the various embodiments described below to describe the principles of the present invention are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com