Convertible modular fixture of multifunctional frictional wear testing machine

A technology of friction and wear test and combined fixture, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that cannot meet the needs of experiments, difficulties in tribological tests, single model of indexable CNC turning blades, etc., and achieve disassembly and assembly Easy and convenient replacement, accurate and effective tribological properties, stable and reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

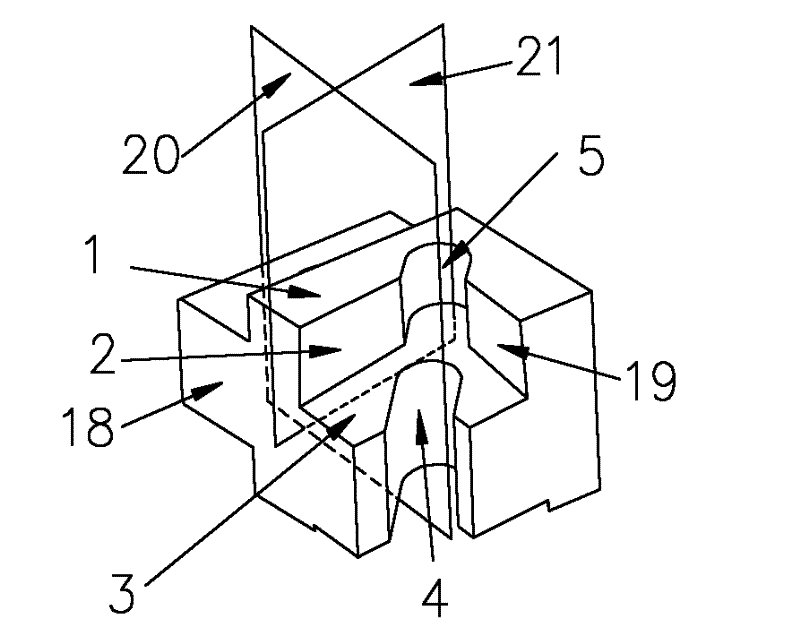

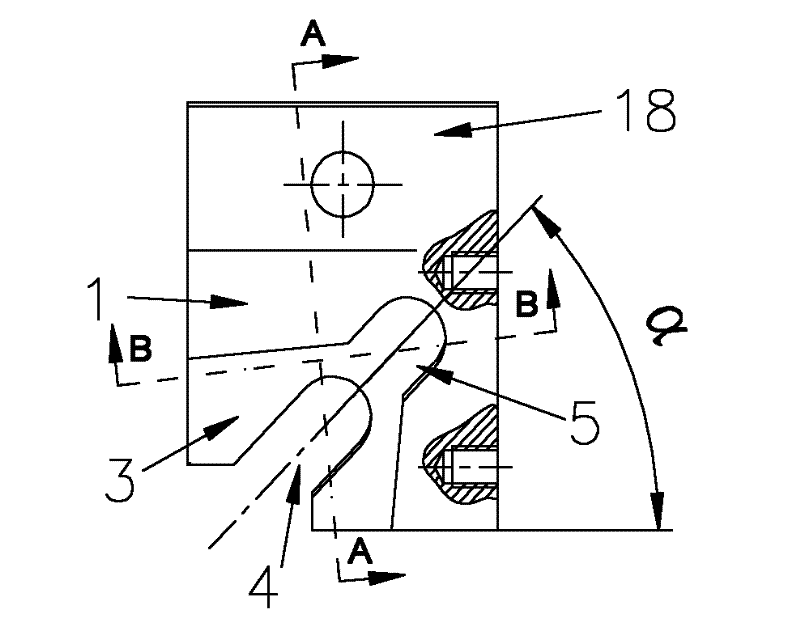

[0032] Such as figure 2 In the example shown, the reference main cutting plane 21 is perpendicular to the base plane 1 and parallel to the intersection line of the groove side 2 and the groove bottom 3, and the reference orthogonal plane 20 is perpendicular to the base plane 1 and the reference main cutting plane 21 at the same time.

[0033] Such as Figure 9 In the example shown, four screws 12 are used to mount the fixture base 6 on the UMT force sensor 11 . The four screws 12 are evenly installed on the four corners of the fixture base 6, so that the clamping of the fixture base 6 on the testing machine is stable and the positioning is accurate.

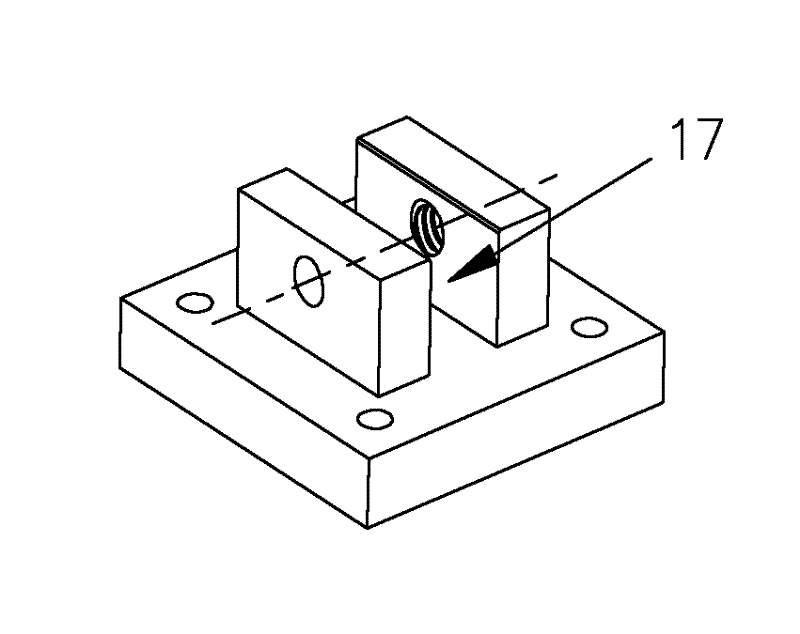

[0034] Then, according to the indexable CNC turning insert 13, select a suitable convertible fixture base 7, such as the CNMG series indexable CNC turning insert 13 shown in the figure as an example, according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com