Modular fixture for partial heat treatment of induction heating and using method thereof

A local heat treatment and induction heating technology, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of out-of-tolerance dimensional accuracy and deformation, complex structure of shape correction fixtures, and difficult manufacturing, etc., to achieve high compressive strength and heat insulation Good effect and reduce manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

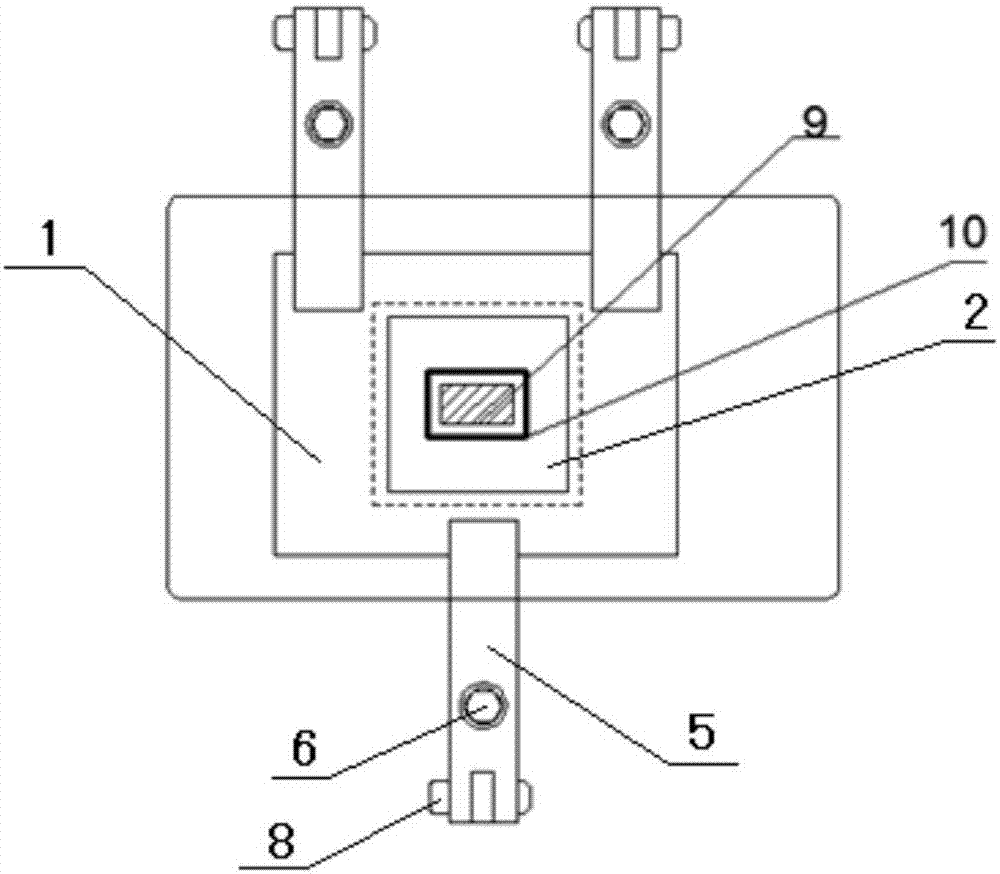

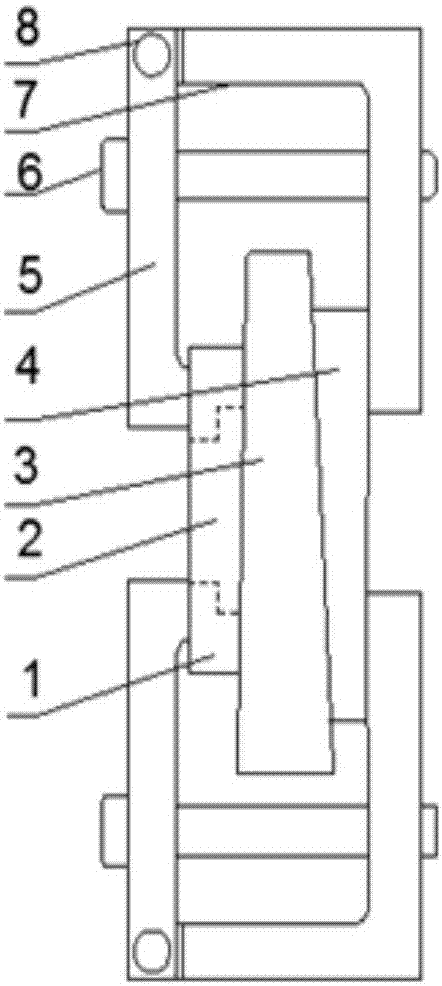

[0028] Such as figure 1 As shown, the present invention provides a modular fixture for induction heating local heat treatment, including a heat-conducting clamp body 2, a heat-insulating clamp body 1, a pressing plate 4 and a pressing mechanism. The heat-conducting clamp body 2 is made of 310S stainless steel, and the heat-insulating clamp body 1 is made of alumina ceramic material.

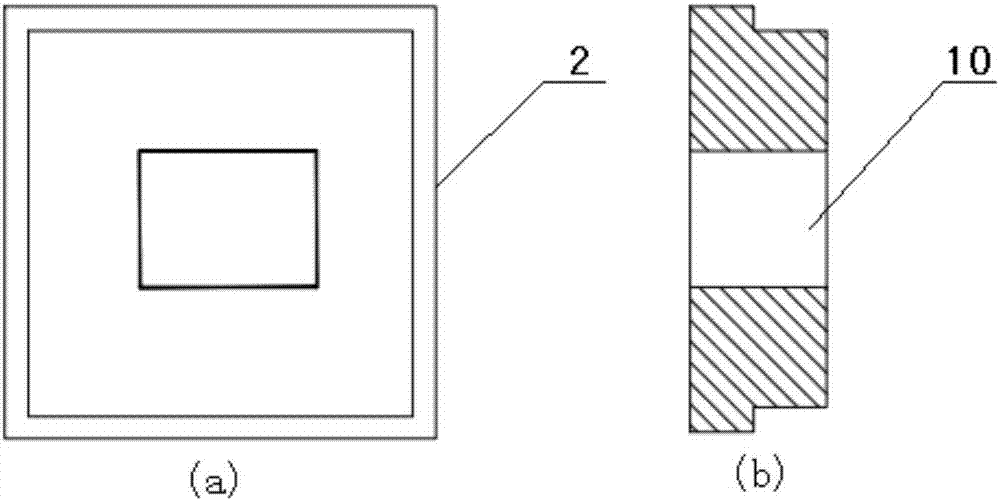

[0029] Such as figure 1 with figure 2 As shown, the bottom surface of the heat-conducting clip body 2 is attached to the surface of the component to be heat-treated, and the interior of the heat-conducting clip body 2 is provided with a through hole 10 passing through its top and bottom s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com