Milling modular fixture

A combined fixture and milling technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high product failure rate, inability to process inclined holes at the same time, low processing efficiency, etc., and achieve a solution The effect of high manufacturing cost, simple structure, and not easy to mix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

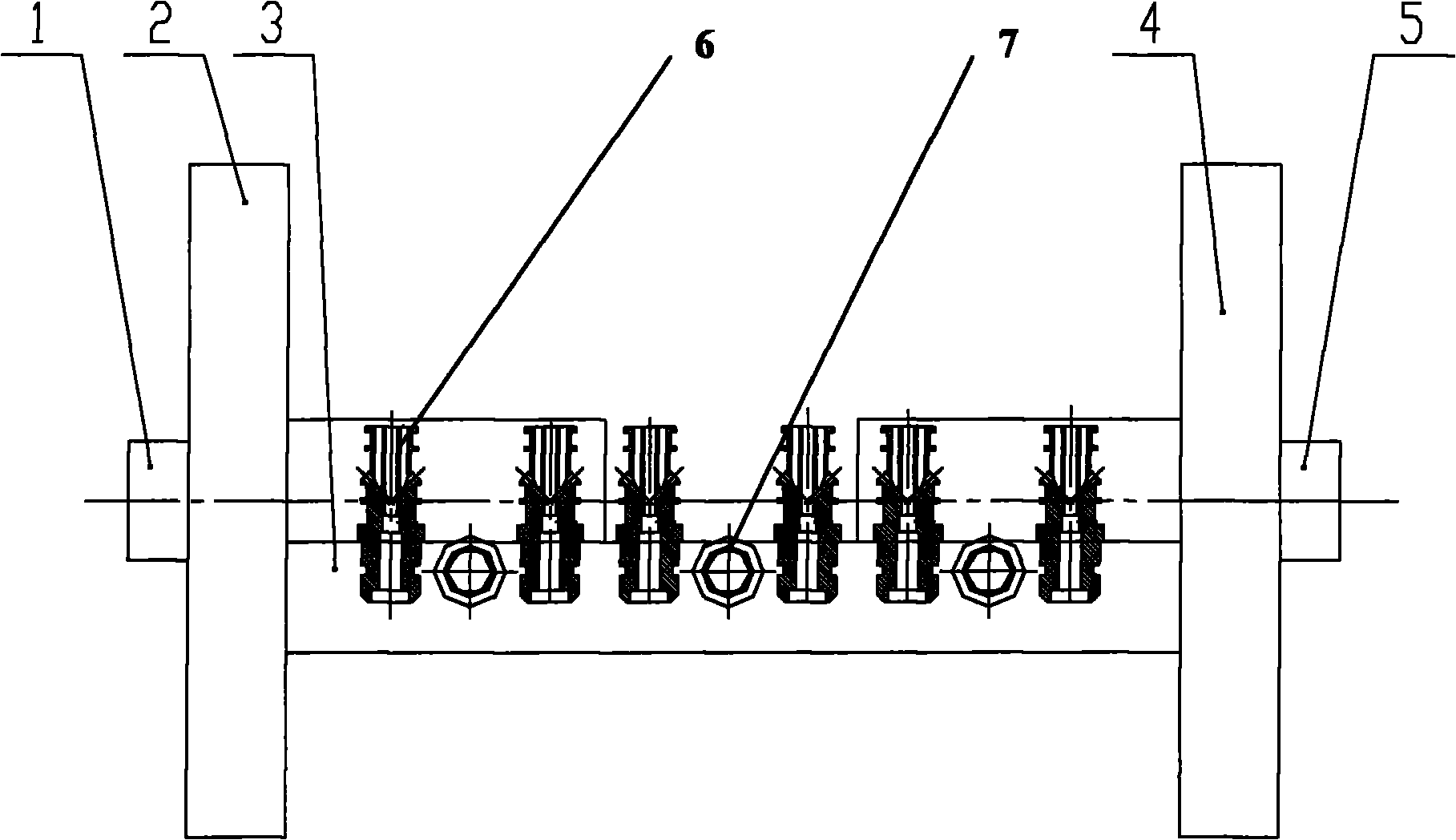

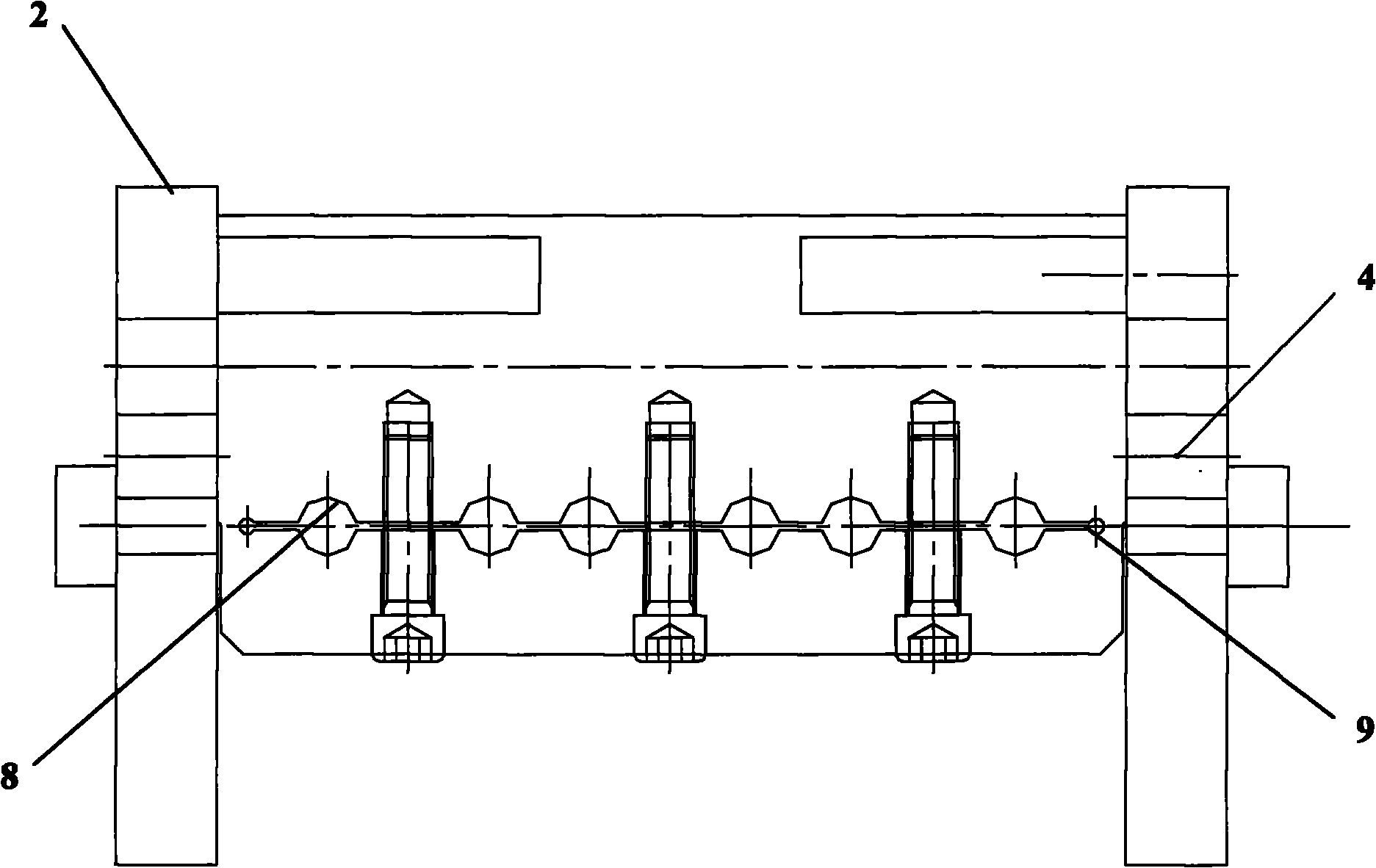

[0010] Such as figure 1 , 2 As shown, the milling combined fixture includes a top connection plate 2, a four-axis connection plate 4, and a positioning plate 3. The central axis 1 of the top connection plate 2 is in contact with the top on the tailstock; the center of the four-axis connection plate 4 The shaft 5 is connected with the four-axis turntable of the machine tool; the positioning plate 3 is provided with a positioning hole 8, an elastic deformation hole 9, and a clamping screw 7; a plurality of workpieces 6 are sequentially clamped in the positioning holes 3, and tightened. The above-mentioned clamping screw 7 utilizes the rotation function of the four-axis turntable to realize one-time processing of multiple holes in the axial and radial directions of the shaft parts. The positioning hole 8 and the elastic deformation hole 9 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com