High-efficient modular fixture for processing part

A group of fixtures and parts processing technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low efficiency, scrapped special fixtures, high fixture costs in the preparation cycle, etc., to expand the process batch, applicable Wide and save the effect of fixture warehouse area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

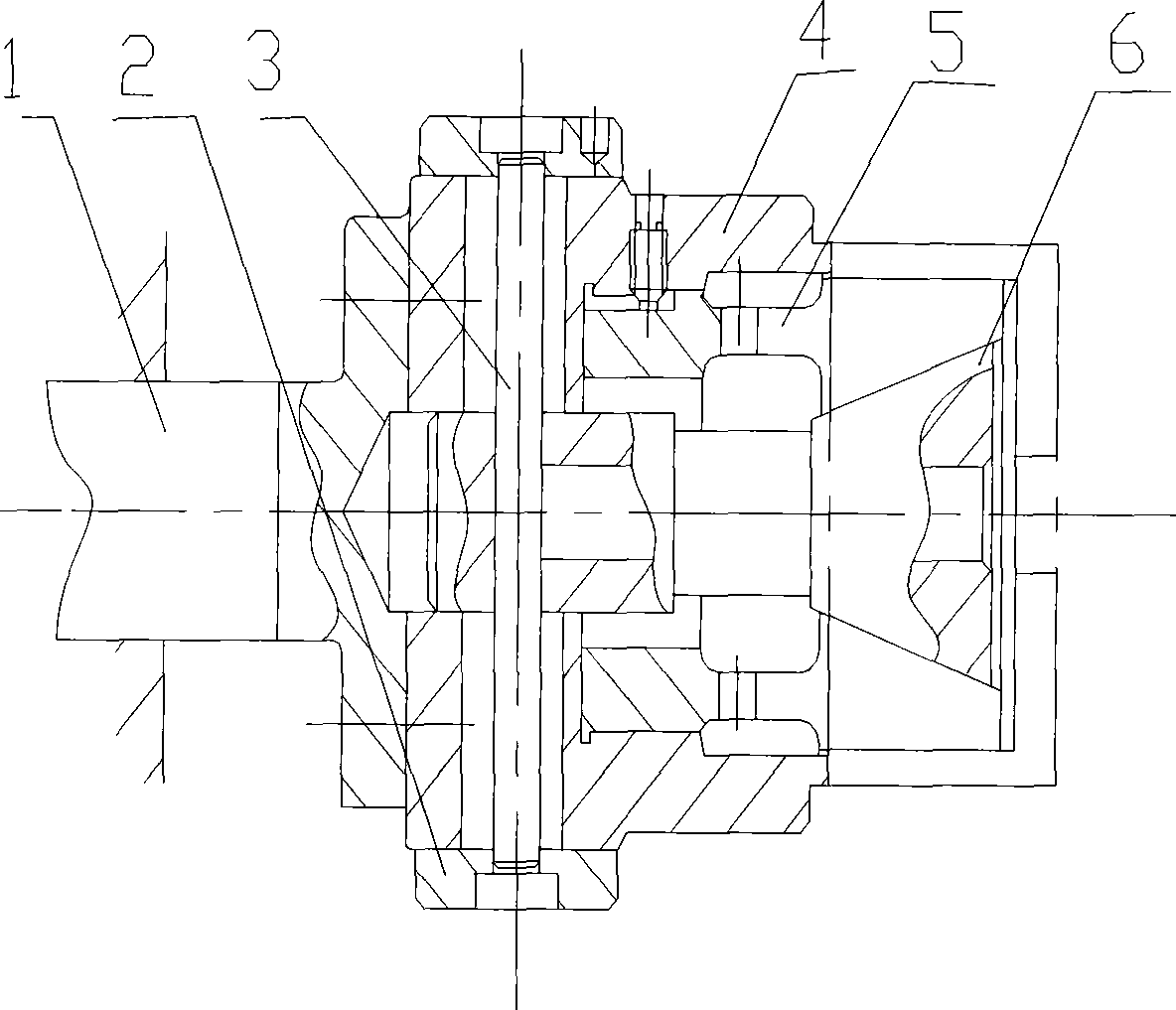

[0017] For ease of understanding, a presently preferred embodiment of the present invention will be further described below in conjunction with the accompanying drawings. attached figure 1 It is an embodiment of processing thin-walled parts with a group of fixtures according to an embodiment of the present invention. The group fixture for part processing of the present invention is mainly composed of a basic part and an adjustable part. exist figure 1 In the shown embodiment, the basic part includes the clamp body 1 , the transmission clamping part composed of the collar 2 and the tie rod 3 ; In the illustrated embodiment, the replaceable element 4 is a clamp connector, and in this embodiment, it is fixed to the clamp body 1 through screw connection. Another replaceable element 6 is a wedge-shaped post 6 inserted into the elastic tire 5 and propped up. The pull rod 3 passes through the hole on the wedge-shaped post 6 , the connection head 4 and the collar 2 to fix the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com