Method for arranging window flushing pipeline

A layout method and pipeline technology, which is applied to ship components, ships, screens with clear vision, etc., can solve the problems of blocking the line of sight, large amount of welding, and blocking of flushing coverage, so as to reduce the construction workload and save design man-hours , reduce the effect of the peripheral pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

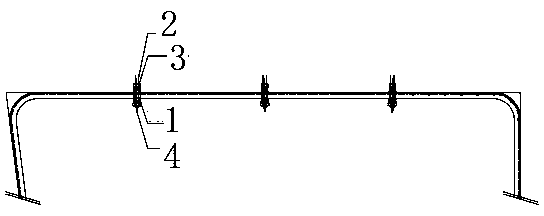

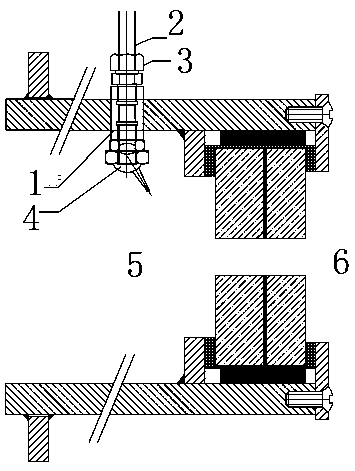

[0011] Such as figure 1 and figure 2 As shown, the layout method of the window flushing pipeline, the specific steps are A, such as figure 1 As shown, in the window withdrawal stage, the model and position dimensions of the opening part 1 are marked on the window drawing, and the thread type of the opening part is determined according to the thread specification of the nozzle 4, and the ferrule is determined according to the size of the water supply pipe 2 3, calculate the coverage of the nozzle 4, determine the position of the penetrating parts on the window, return the above technical requirements to the window manufacturer, and make it according to the requirements; For the water supply pipe, install nozzles outdoors; C. Adjust the angle of the nozzles after water supply to ensure that the windows can be covered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com