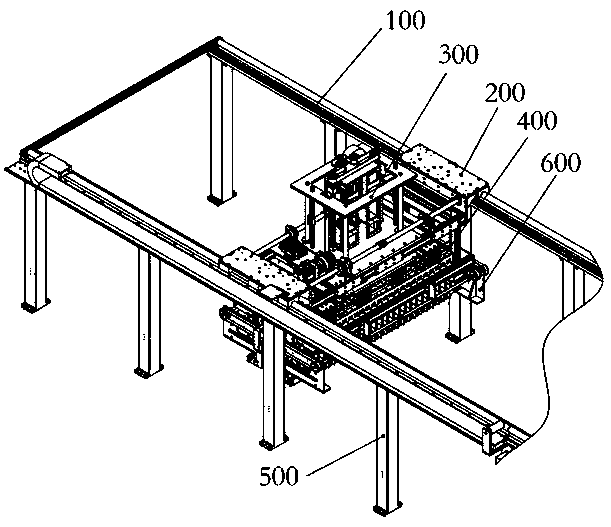

Lithium battery modular clamp device

A combination fixture and lithium battery technology, which is applied in the direction of chucks, manufacturing tools, manipulators, etc., can solve the problems of cost increase and occupied space, and achieve the effect of saving cost and avoiding space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

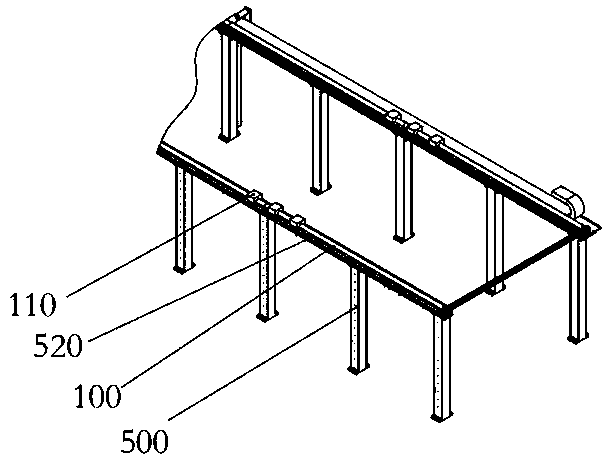

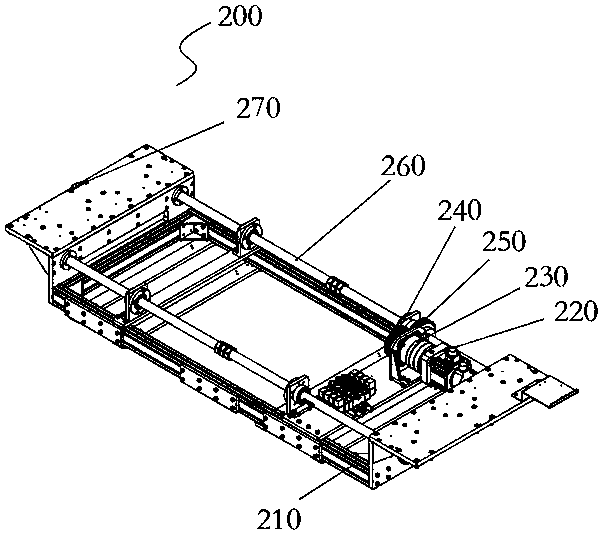

[0047] In order to make the objectives, technical solutions and advantages of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0048] In the prior art, the most commonly used method for picking and placing lithium batteries in the high-temperature pressure forming process is that the feeding tray flows to the high-temperature forming station; the manipulator or manual placement, one lithium battery is picked and placed into the forming unit at a time; Or manually take out the lithium battery and put it into the unloading tray. However, when the production output of lithium batteries is high, the number of formation units will be large, and multiple sets of robots or workers need to be used for placement, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com