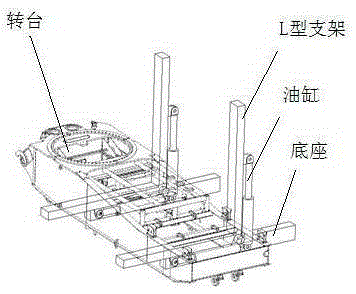

End-to-end type modular fixture and reversing machine comprising same

A combined fixture, head and tail technology, applied in manufacturing tools, workpiece clamping devices, workbenches, etc., can solve the problems of unstable turning process, long driving time, poor operating comfort, etc., and achieve convenient, fast and simplified installation. The assembly process and the effect of convenient card installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

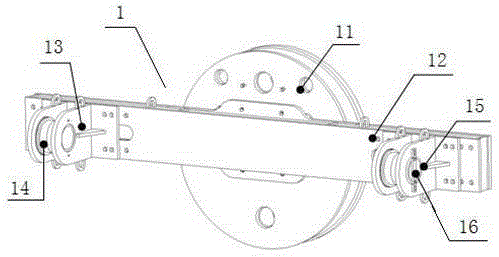

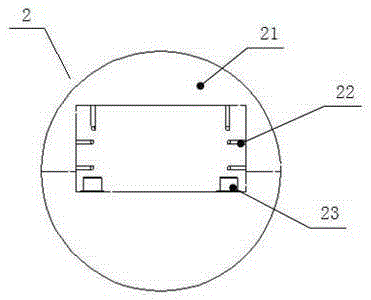

[0023] Such as figure 2 and image 3 As shown, a head-to-tail combination clamp includes a front clamping device 1 and a tail clamping device 2;

[0024] The front clamping device 1 is composed of a rotary connecting plate 11, a crossbeam 12, and lugs 13. The rotary connecting plate 11 is connected to the middle of the crossbeam 12. The connection between the crossbeam 12 and the rotary connecting plate 11 adopts a combination of pin shaft and bolt connection. Two positioning pins are welded on the crossbeam 12, and there are corresponding pins and bolt mounting holes on the rotary connecting plate 11. Two long keyways and multiple sets of threaded holes with different spacings are symmetrically provided at both ends of the crossbeam 12; the lugs 13 There are two groups, which are arranged symmetrically at both ends of the beam 12. The centers of the two lugs 13 are loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com