Composite pile structure suitable for coastal deep reclaimed soil foundation treatment and construction method

A soil foundation and composite pile technology, which is applied in the direction of foundation structure engineering, soil protection, sheet pile wall, etc., can solve the problems of not being able to meet the bearing capacity, deformation control and cost saving, and reducing bearing capacity at the same time, so as to increase the pile and soil. Anchoring effect, ensuring bearing capacity, reducing the effect of foundation deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

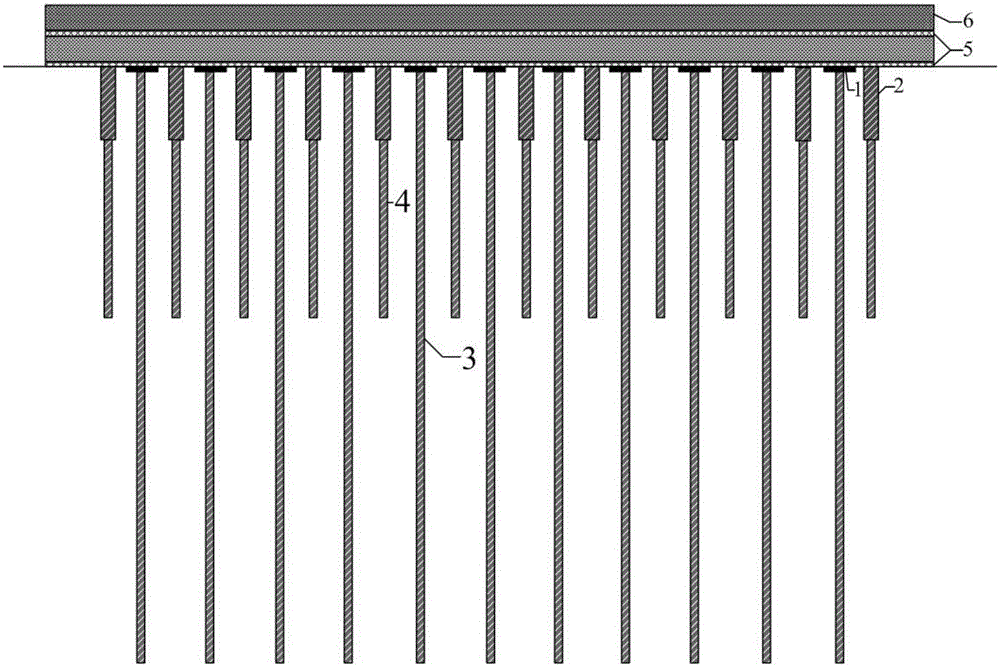

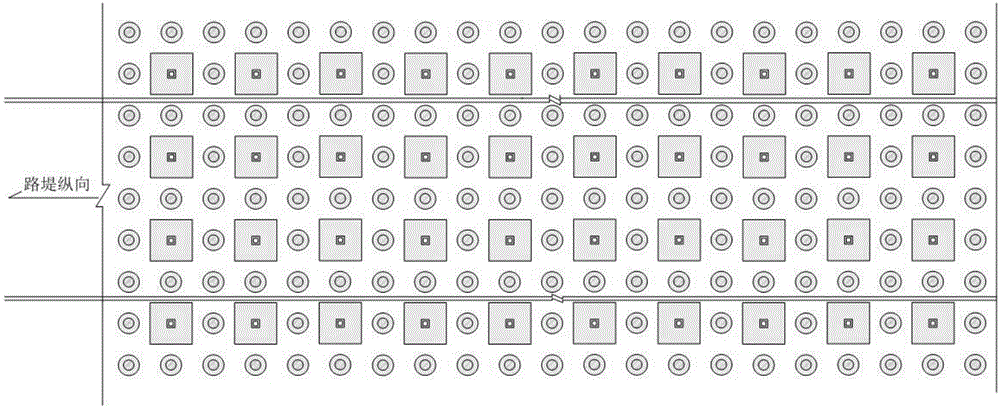

[0027] A new type of composite pile used for foundation treatment of coastal deep dredger fill, including prestressed concrete thin-walled hollow square pile, nail-type two-way mixing powder-jet pile and upper cushion. Prestressed concrete thin-walled hollow square piles and nail-type two-way mixing powder-sprayed piles are arranged vertically and horizontally at equal intervals, and prestressed concrete thin-walled hollow square piles are arranged in every row, and the same row of prestressed concrete thin-walled hollow square piles and The nail-shaped two-way mixing powder spraying piles are arranged at intervals. In the horizontal or vertical rows of nail-type two-way mixing powder-spraying piles, a nail-type two-way mixing powder-spraying pile is provided in the middle of two adjacent nail-type two-way stirring powder-spraying piles, and makes the composite pile structure The outer layer is a nail-type two-way mixing powder spraying pile, such as figure 2 shown.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com