SDDC pile ground structure construction method

A construction method and ground structure technology, applied in foundation structure engineering, sheet pile walls, soil protection, etc., can solve problems such as single filler, poor economy, and hole penetration, and achieve improved load-bearing capacity, improved bearing capacity, and uniform stiffness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

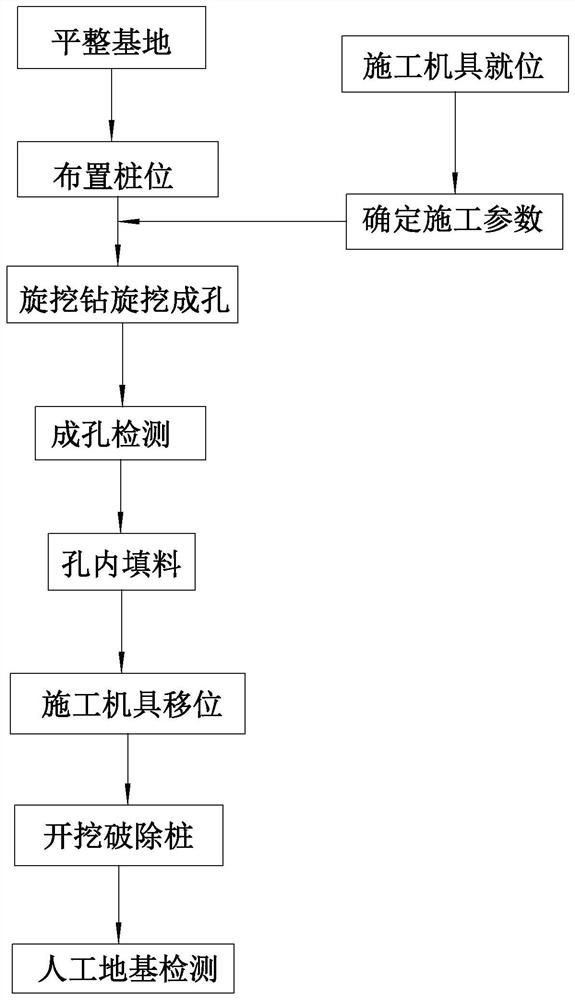

[0045] refer to figure 1 , is a kind of SDDC pile-ground structure construction method disclosed by the present invention, with reference to figure 1 , including the following steps:

[0046] (1) Leveling the base: First, excavate the foundation to be constructed. After excavation, the bottom of the foundation pit is uneven, which is not convenient for the pile driver to be in place and cannot guarantee the verticality of the pile body. The foundation is leveled by the loader.

[0047] (2) Arrangement of pile positions: measure and set out the lines, release the positions of each pile according to the design drawings, and drill holes with steel brazing to form holes. The holes require that the pile points can still be found after removing the disturbed soil layer on the surface.

[0048] (3) The construction equipment is in place: the rotary drilling drill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com