Vibration pressurizing quick solidification soft foundation processing method

A soft foundation and fast technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of slope stability, limited foundation bearing capacity, high cost, etc., and achieve small post-construction settlement, large treatment depth, The effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

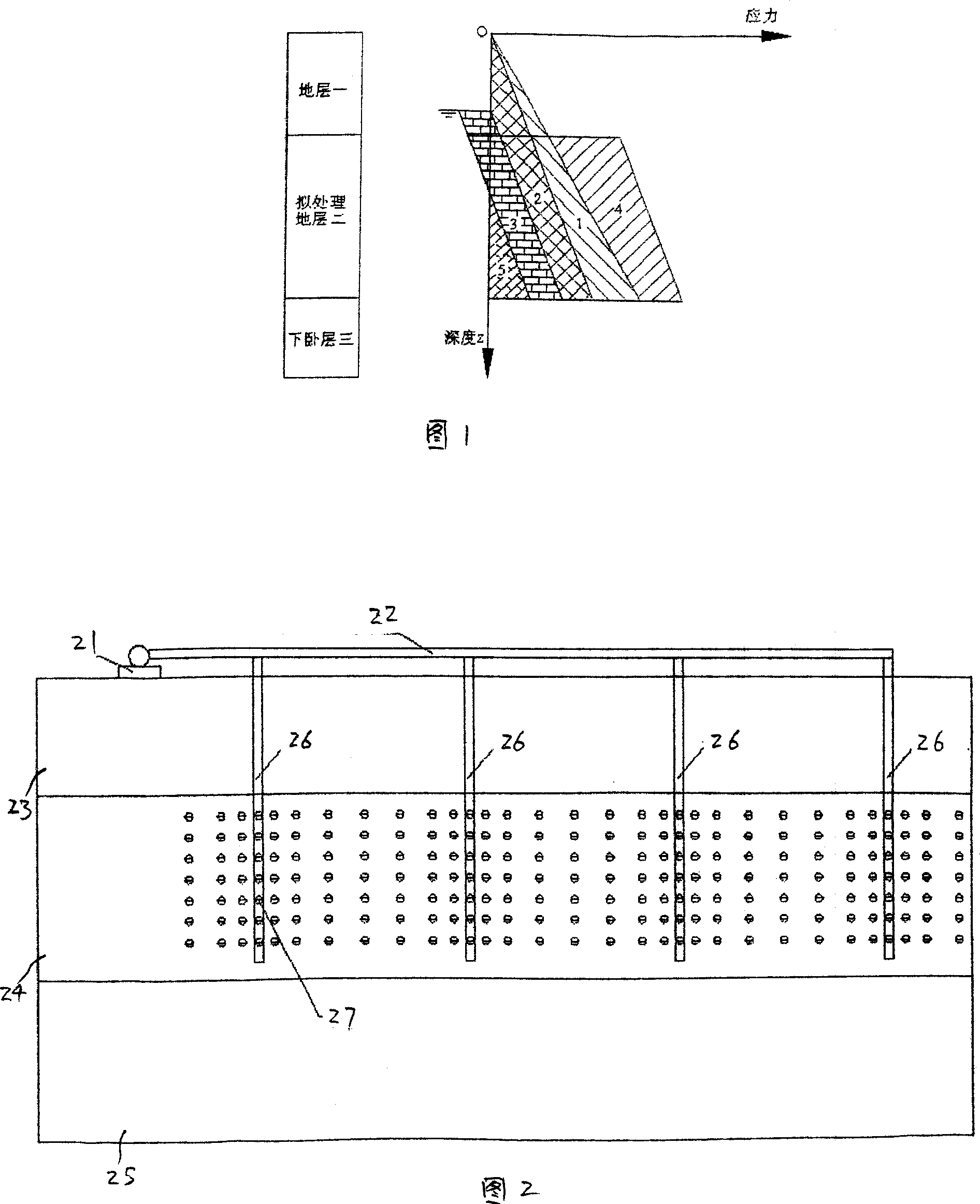

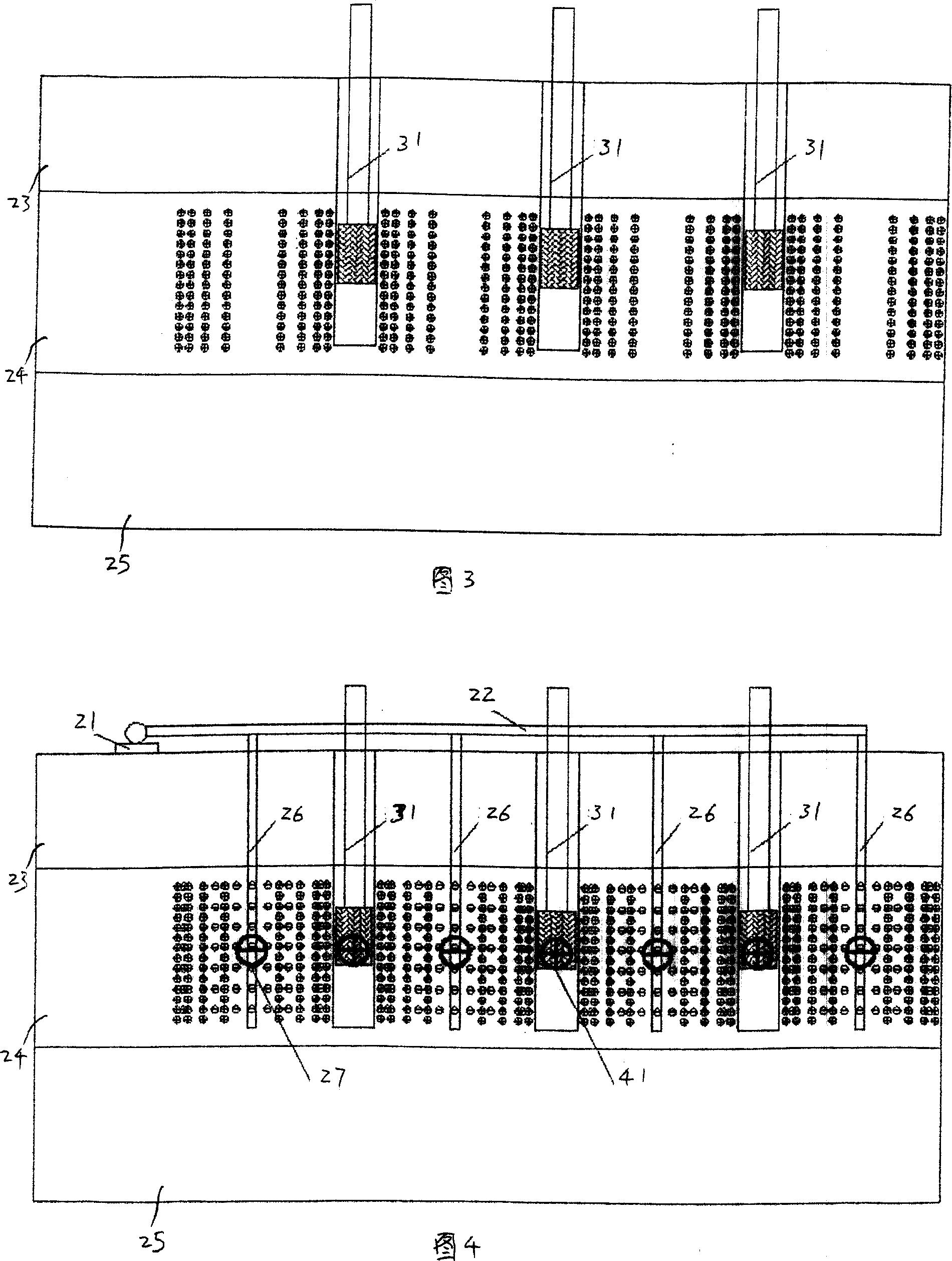

[0015] In Fig. 1: 1 is the effective stress before treatment; 2 is the effective stress increased by precipitation; 3 is the effective stress increased by vacuum pumping; 4 is the effective stress increased by vibration; 5 is the remaining pore water pressure after treatment. In Fig. 2: 21 is a vacuum pump; 22 is a horizontal drainage channel; 23 is stratum 1; 24 is stratum 2 to be treated; 25 is underlying stratum 3; 26 is a vacuum tube; 27 is a negative pressure zone centered on the vacuum tube. In Fig. 3: 23 is stratum 1; 24 is stratum 2 to be treated; 25 is underlying stratum 3; 31 is a vibrator. Among Fig. 4: 21 is a vacuum pump; 22 is a horizontal drainage channel; 23 is a formation one; 24 is a formation two to be treated; 25 is an underlying formation three; 26 is a vacuum tube; 27 is a negative pressure zone centered on the vacuum tube; 31 is Vibrator; 41 is the positive pressure zone of excess pore water pressure centered on the vibrator.

[0016] The vibration pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com