A two-stage hydraulic rotary jet block cleaner

A technology of hydraulic rotation and blockage remover, which is applied in wellbore/well components, earthwork drilling, flushing wellbore, etc. It can solve problems such as damage, failure to realize automatic reciprocating motion, and damage to pipeline integrity, so as to improve the treatment depth , Concentrated energy and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

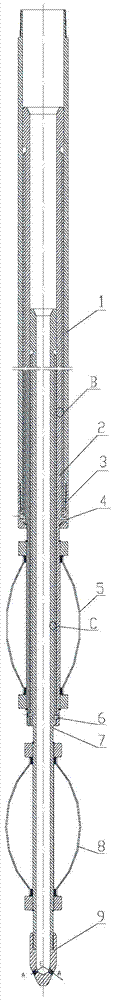

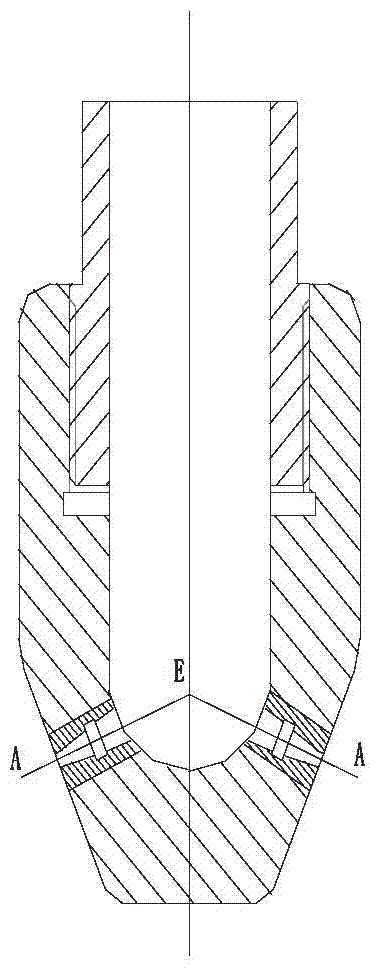

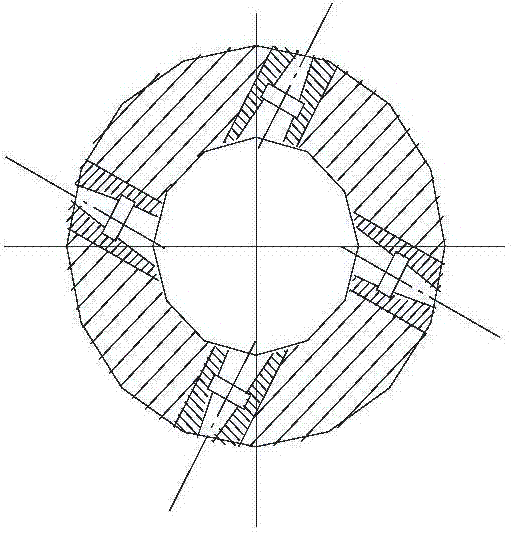

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0029] see Figure 1 to Figure 4 , a two-stage hydraulic rotary jet blockage remover, including an outer cylinder 1, a first-stage screw rod 2, a connecting end cover 3, a first-stage pin 4, a first-stage centralizer 5, a second-stage pin 6, a second-stage screw rod 7, and a second-stage The centralizer 8 and the rotary nozzle 9; the primary screw 2 is sleeved on the outer side of the upper part of the secondary screw 7, and the outer cylinder 1 is sleeved on the outer side of the upper part of the primary screw 2. The matching relationship is clearance fit, and the connecting end cover 3 is connected At the lower end of the outer cylinder 1, the connection between the outer cylinder 1 and the connecting end cover 3 is a taper thread connection with a taper of 1:16. The rotary nozzle 9 is connected to the bottom of the secondary screw 7. There are four nozzles evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com