Separation method of alkaline liquid in production of alumina

A technology of alkaline material liquid and separation method, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of insufficient yield, low alkali purity, long time, etc., achieve fast separation speed, improve purity, and increase yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

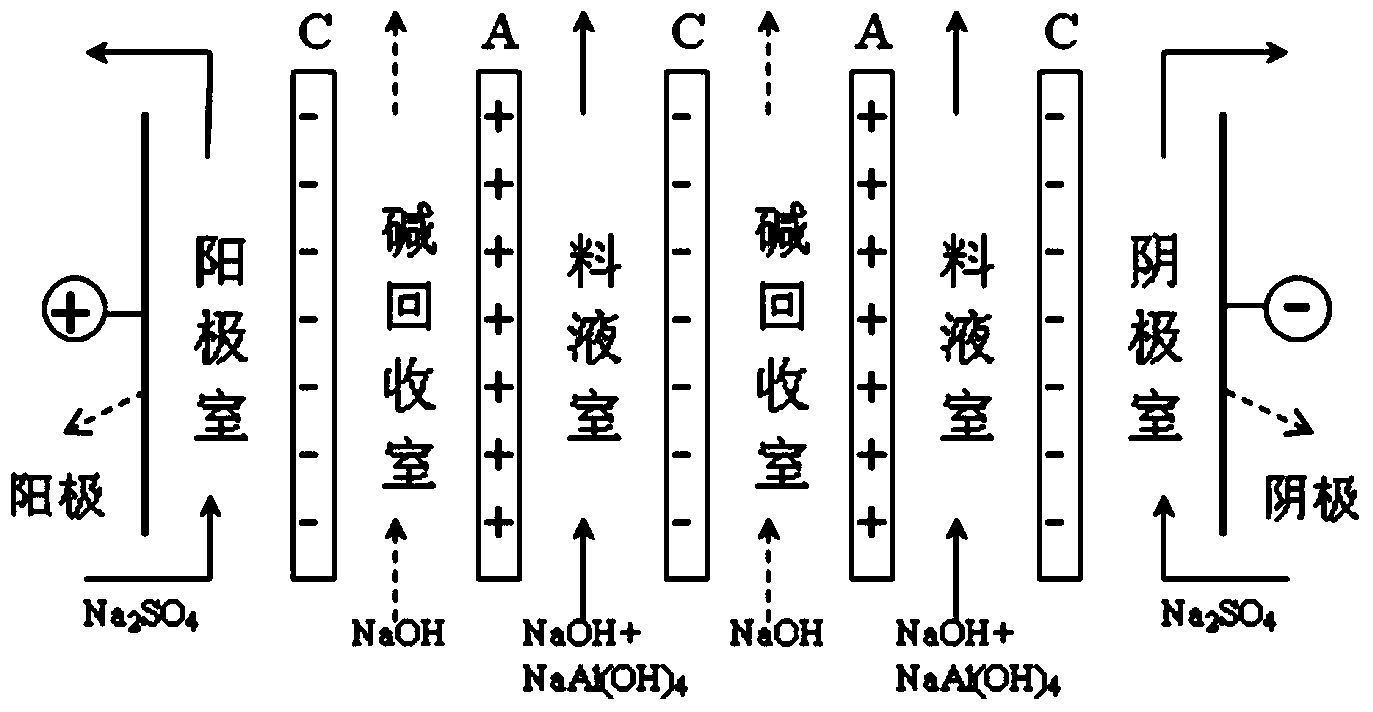

[0023] This embodiment adopts such as figure 1 The electrodialysis device shown is composed of an anode chamber and a cathode chamber respectively located on both sides and an electrodialysis compartment sandwiched between the anode chamber and the cathode chamber; the electrodialysis compartment is composed of a cation exchange membrane C and an anion exchange membrane Two "alkali recovery chamber and material liquid chamber units" arranged in intervals are arranged repeatedly (the membrane stack is C-A-C-A-C); the anode and the adjacent cation exchange membrane form the anode chamber, and the cathode and the adjacent cations The exchange membrane interval constitutes the cathode chamber; the effective area of a single cation exchange membrane or a single anion exchange membrane is 5.7cm 2 , the distance between the anode or cathode and the cation exchange membrane C, and between the cation exchange membrane C and the anion exchange membrane A is 1 cm. The cation exchange ...

Embodiment 2

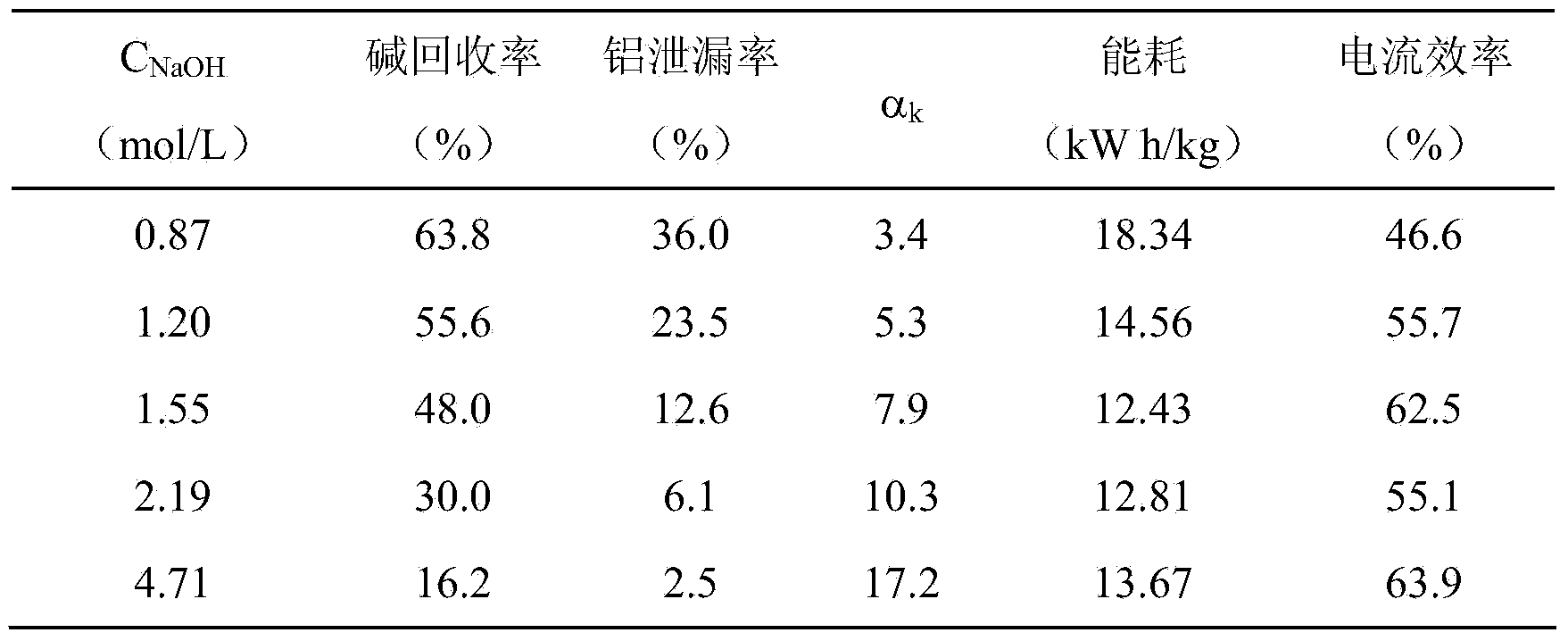

[0031] The electrodialysis unit used in this embodiment, cation exchange membrane, anion exchange membrane, strong electrolyte solution and the dilute lye of alkali recovery chamber are identical with embodiment 1, and alkaline feed liquid is NaOH and NaAl(OH) 4 The mixed solution, the concentration of NaOH is 1.55mol / L, NaAl(OH) 4 The concentration is 0.81mol / L. The control current density is 87.5, 175.0, 262.5, 350.0, 437.5mA / cm 2 , the electrodialysis experiment was carried out, and the running time was 4 hours. The results are shown in Table 2.

[0032] Table 2 Effect of current density on alkali recovery rate, aluminum leakage rate, caustic ratio of solution in alkali recovery chamber (α k ), energy consumption and current efficiency

[0033]

[0034] From the results in Table 2, it can be seen that with the increase of current density, the alkali recovery rate, aluminum leakage rate and energy consumption all gradually increase, and the solution α in the alkali rec...

Embodiment 3

[0036] The strong electrolyte solution used in this example and the dilute lye in the alkali recovery chamber are the same as in Example 1, the alkaline feed solution is the same as in Example 2, the cation exchange membrane is the same as in Example 1, and the anion exchange membrane is based on Chinese patent ZL201210206572.6 (a method for preparing an organic-inorganic hybrid anion exchange membrane based on BPPO and PVA) produced AM-QP-30 membrane. After soaking in 2.0mol / L NaOH at 65°C for 60 hours, the swelling degree of the membrane was 91%, and the mass loss rate was 8%, which indicated that the membrane had strong alkali resistance.

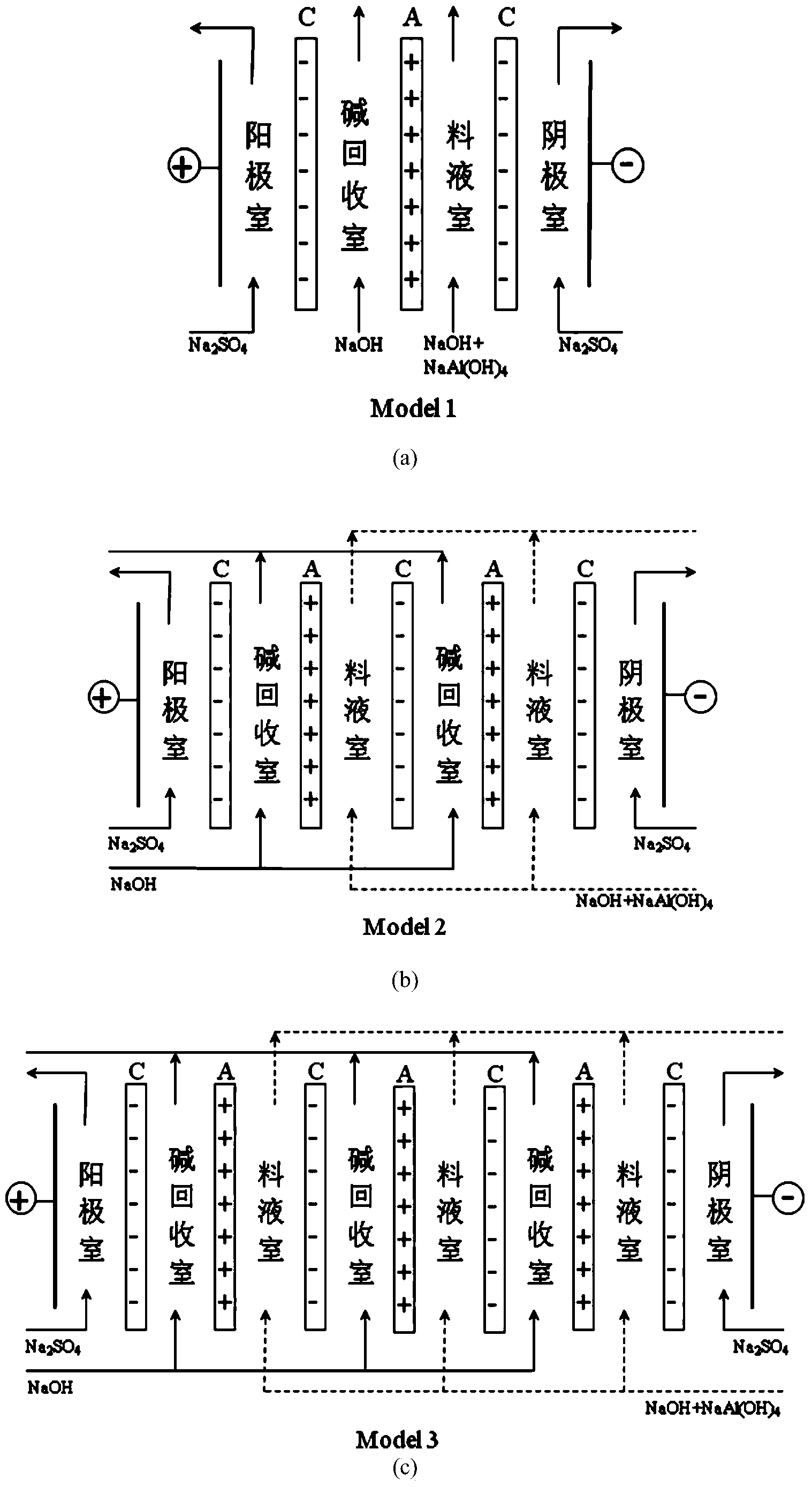

[0037] The electrodialysis devices used in this example are as follows: figure 2 The three shown are respectively a unit containing one alkali recovery chamber and a feed liquid chamber (named model1), a unit containing two alkali recovery chambers and a feed liquid chamber (named model2), and a unit containing three alkali recovery cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com