Method for recovering toluene

A technology of toluene and exhaust gas, applied in the direction of adsorption purification/separation, organic chemistry, etc., can solve the problems of high cost, poor effect, low recovery rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

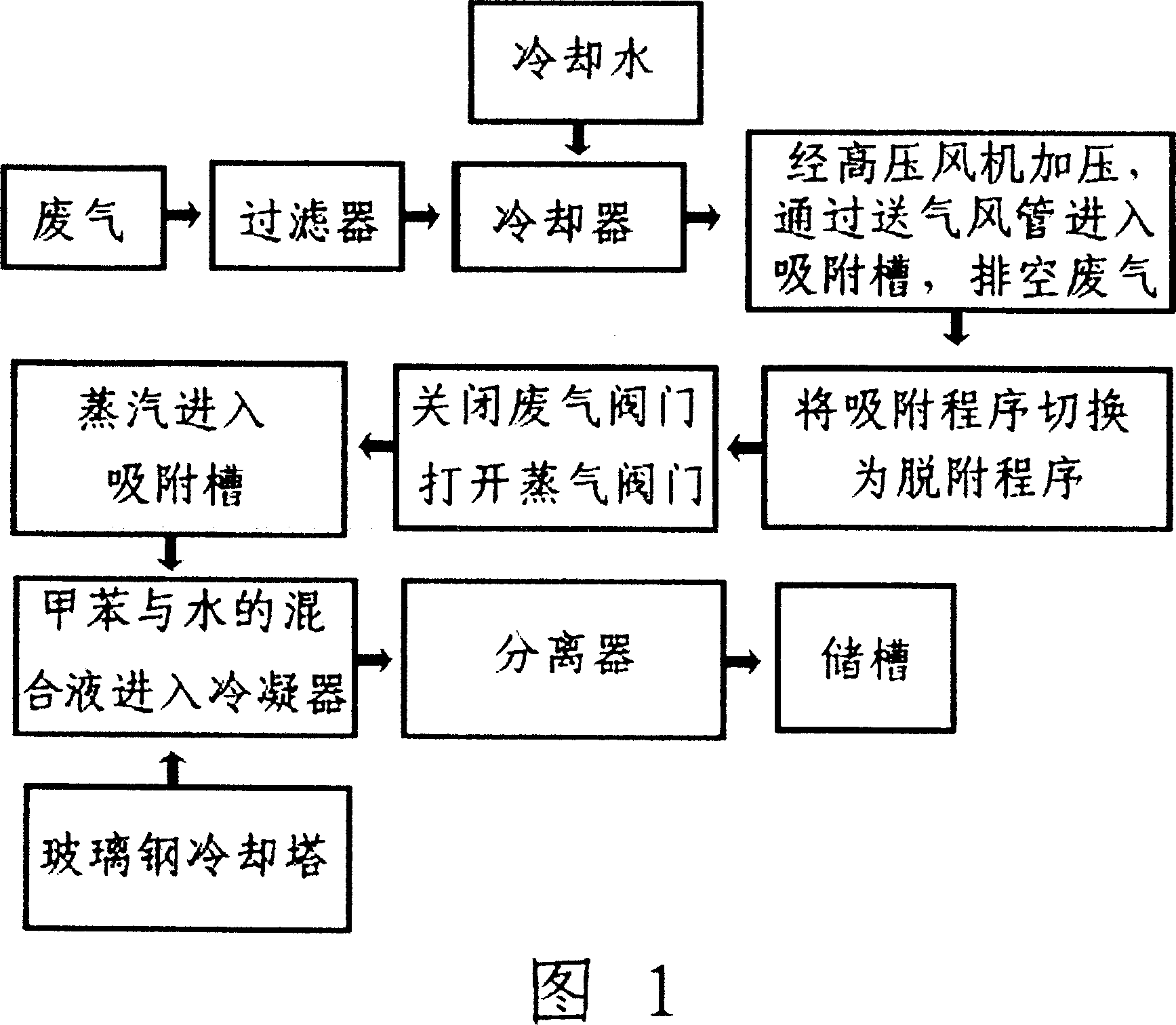

[0041] As shown in Figure 1, the method for reclaiming toluene mainly comprises the following major steps:

[0042] 1. The waste gas generated in the production passes through the control valve and enters the gas filter first. The filter made of non-woven fabric separates impurities such as fibers and dust in the waste gas, so as to avoid blocking the cooler and activated carbon.

[0043] 2. After passing through the cooler, the cooler is composed of copper tubes and aluminum sheets. There is recyclable cooling water in the cooler to cool the waste gas including toluene gas. After the cooling water is cooled, the temperature of the waste gas is reduced from 76°C to Around 40°C, the lower temperature is conducive to the absorption of toluene by activated carbon.

[0044] 3. The cooled exhaust gas is pressurized by a high-pressure fan and enters three adsorption tanks respectively through the air supply duct. The adsorption tank is filled with activated carbon. Since the activat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com