Solid-liquid separation process for preparing isophthalodinitrile

A technology of isophthalonitrile and solid-liquid separation, applied in the direction of organic chemistry, can solve the problems of reducing the service life of filter cloth, affecting the working environment of workers, and ammonia gas escape, so as to improve labor efficiency, reduce labor intensity, The effect of improving usage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

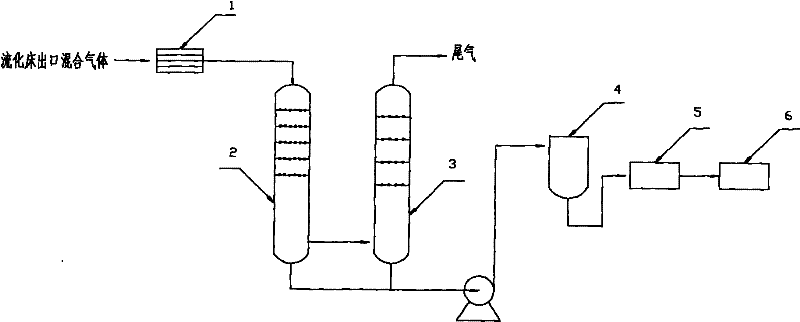

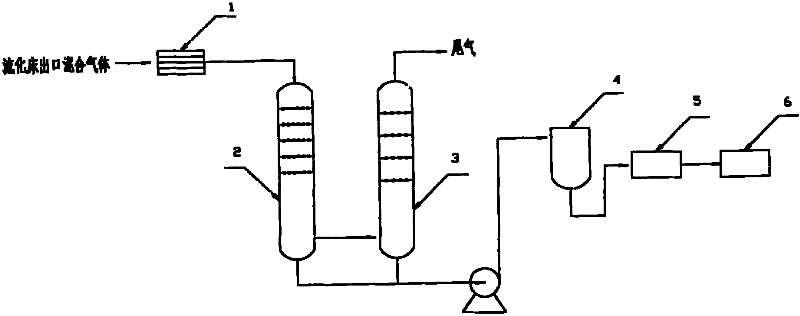

[0015] A solid-liquid separation process for preparing isophthalonitrile. The mixed gas at the outlet of the fluidized bed reactor is cooled by the oil cooler 1 and then enters from the upper part of the primary water spray tower 2, and the mixed gas at the outlet of the primary water spray tower 2 It enters from the bottom of the secondary water spray tower 3 and exits from the top. The solid-liquid mixture in the primary and secondary water spray towers first enters the settling tank 4 for settling, the slurry with a high concentration of isophthalonitrile at the bottom of the settling tank enters the centrifuge 5, and the centrifuge outlet material finally enters the drying equipment 6.

[0016] The first-level water spray tower is an empty tower with 3-9 layers of coils inside, and each layer of coils has 2-16 atomizing nozzles.

[0017] The secondary water spray tower is an empty tower with 3-9 layers of coils inside, and each layer of coils has 2-16 atomizing nozzles.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com