Preparation method of super-hydrophobic sponge adsorbing material

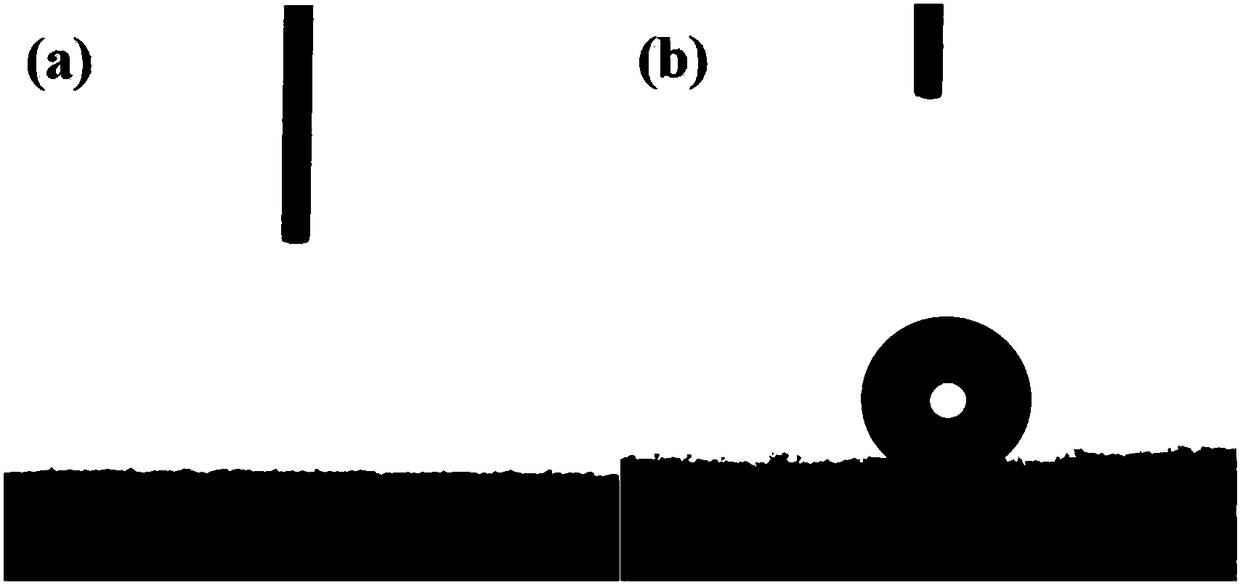

A super-hydrophobic sponge and adsorption material technology, which is applied in the field of environmental functional material preparation, can solve the problems of poor stability, small processing capacity, and low recycling rate, and achieve the effects of stable performance, large adsorption capacity, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of dopamine-coated sponge body: Put the sponge into ethanol for ultrasonic pretreatment for 10 minutes, put it in an oven and dry it at 60°C; Add 0.2 g of dopamine hydrochloride, then put the cleaned sponge into the above solution, shake in a water bath shaker at 25° C. for 6 hours, and shake at a speed of 100 r / min. After the shaking is completed, the sponge is taken out, washed with ethanol several times, and dried in an oven at 60°C. get polydopamine coated sponge

[0033] (2) Preparation of superhydrophobic sponge: dissolve 0.05g of cetyltrimethoxysilane, 0.25g of tetraethyl silicate, and 2mL of ammonia water in 20mL of ethanol, put the dried sponge in a water bath for 60 ℃ heating and stirring for 30min, the stirring speed is 20r / min. Then transfer to a shaker at 25°C for 24h, the shaking speed is 120r / min. After the shaking is completed, the sponge is taken out, washed with ethanol several times, and placed in an oven at 60°C to dry to obtain a ...

Embodiment 2

[0035] (1) Preparation of dopamine-coated sponge body: Put the sponge into ethanol for ultrasonic pretreatment for 10 minutes, put it in an oven and dry it at 60°C; Add 0.2 g of dopamine hydrochloride, then put the cleaned sponge into the above solution, shake in a water bath shaker at 25° C. for 6 hours, and shake at a speed of 110 r / min. After the shaking is completed, the sponge is taken out, washed with ethanol several times, and dried in an oven at 60°C. get polydopamine coated sponge

[0036] (2) Preparation of superhydrophobic sponge: dissolve 0.15g of cetyltrimethoxysilane, 0.25g of tetraethyl silicate, and 2mL of ammonia water in 30mL of ethanol, put the dried sponge in a water bath for 60 ℃ for heating and stirring for 30 min at a stirring speed of 30 r / min, and then transferred to a shaker at 25 ℃ for 12 h at a shaking speed of 130 r / min. After the shaking is completed, the sponge is taken out, washed with ethanol several times, and dried in an oven at 60°C to obt...

Embodiment 3

[0038] (1) Preparation of dopamine-coated sponge body: Put the sponge into ethanol for ultrasonic pretreatment for 10 minutes, put it in an oven and dry it at 60°C; Add 0.2 g of dopamine hydrochloride, then put the cleaned sponge into the above solution, and vibrate (120 r / min) in a water bath shaker at 25° C. for 6 h. After the shaking is completed, the sponge is taken out, washed with ethanol several times, and dried in an oven at 60°C. get polydopamine coated sponge

[0039] (2) Preparation of superhydrophobic sponge: dissolve 0.25g of cetyltrimethoxysilane, 0.25g of tetraethyl silicate, and 2mL of ammonia water in 40mL of ethanol, put the dried sponge in a water bath for 60 ℃ heating and stirring for 30min at a stirring speed of 40r / min, and then transferred to a shaker at 5℃ for 6h at a shaking speed of 140r / min. After the shaking is completed, the sponge is taken out, washed with ethanol several times, and dried in an oven at 60°C to obtain a superhydrophobic and lipop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com