Method for continuously purifying and refining ortho toludiamine

A technology of o-toluene diamine and storage tank is applied in the field of continuous purification and purification of o-toluene diamine, which can solve the problems of high impurity content and affecting the quality of tolyltriazole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

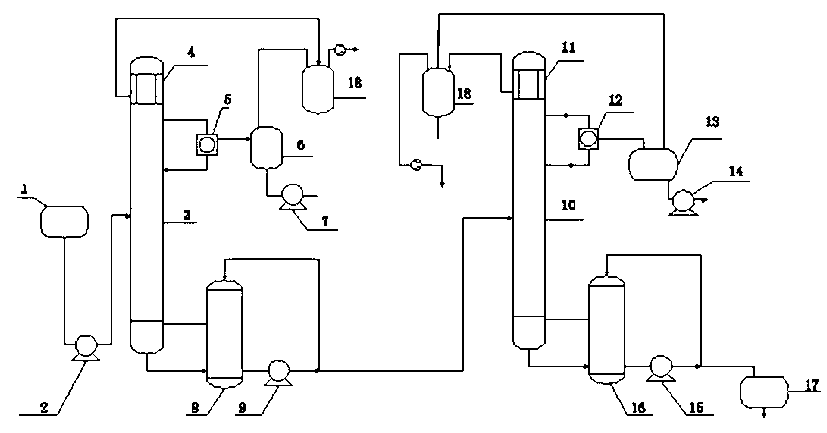

Image

Examples

Embodiment 1

[0016] Embodiment 1: tower control process condition:

[0017] .

[0018] It can be obtained from the above table: under the above process conditions, after two towers are connected in series for rectification, the product rectification tower o-xylylenediamine is discharged from the top of the tower, and its content is ≥ 99.5%, m-toluenediamine ≤ 0.35%, Toluidine≤0.05%, H 2 O≤0.1%.

Embodiment 2

[0019] Embodiment 2: tower control process condition:

[0020] .

[0021] It can be obtained from the above table: under the above process conditions, after two towers are connected in series for rectification, the product rectification tower o-xylylenediamine is discharged from the top of the tower, and its content is ≥ 99.65%, m-toluenediamine ≤ 0.26%, Toluidine≤0.04%, H 2 O≤0.05%.

Embodiment 3

[0022] Embodiment 3: tower control process condition:

[0023] .

[0024] It can be obtained from the above table: under the above process conditions, after two towers are connected in series for rectification, the product rectification tower o-xylylenediamine is discharged from the top of the tower, and its content is ≥ 99.6%, m-toluenediamine ≤ 0.34%, Toluidine≤0.06%, H 2 O≤0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com