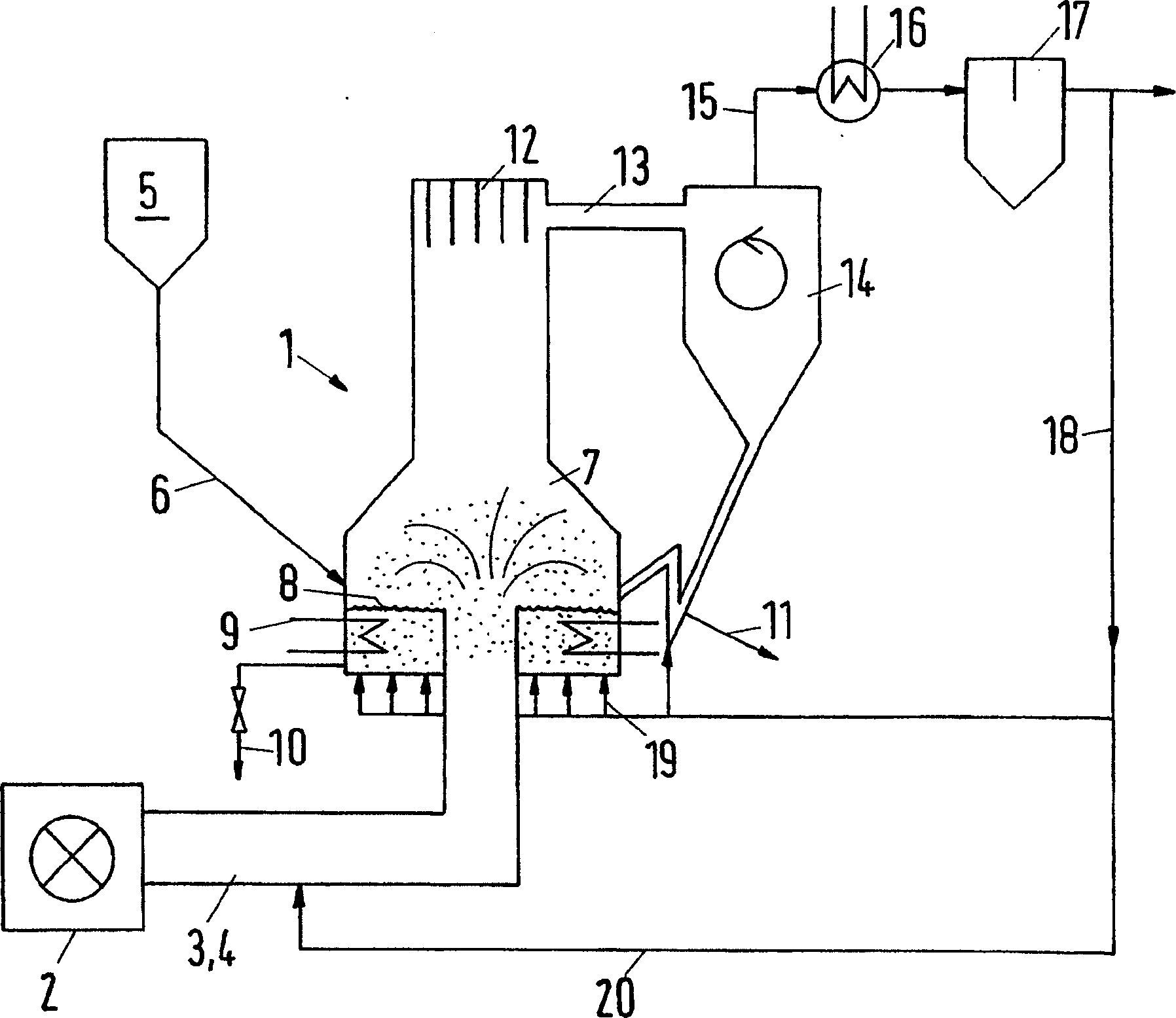

Treatment of granular solids in an annular fluidized bed with microwaves

A granular solid, fluidized bed technology, applied in microwave heating, drying of solid materials, chemical/physical/physical-chemical processes of applying energy, etc., can solve problems such as weakening microwave radiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

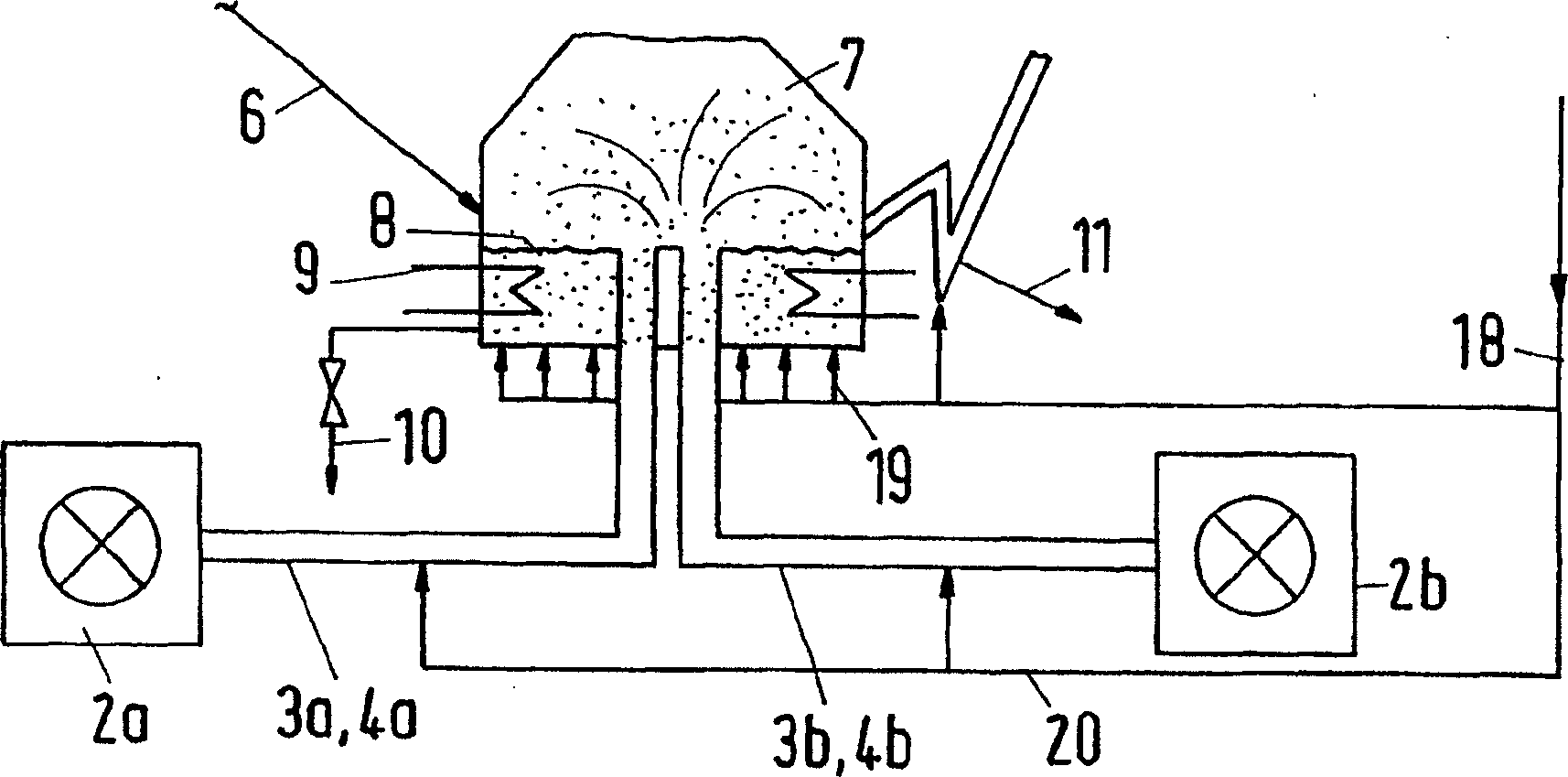

Method used

Image

Examples

Embodiment

[0054] Embodiment (calcined gold ore)

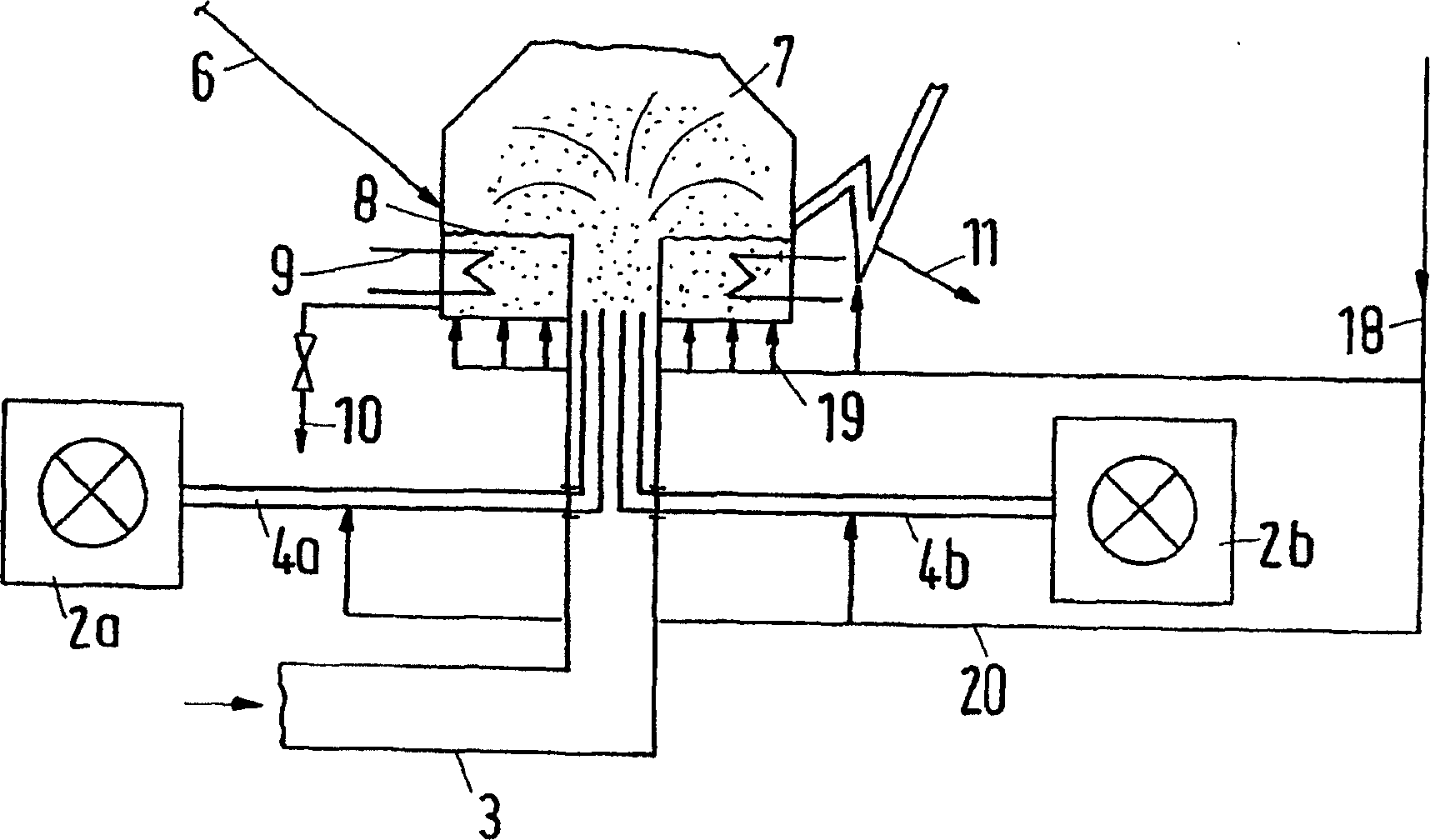

[0055] A specific example of the method of the present invention is the calcining of gold ore, which is image 3 performed in the device shown.

[0056] In this application, the Froude number Fr of the particles in the fixed annular fluidized bed 8 p About 0.35, the particle Froude number Fr in the mixing chamber 7 p About 1.3, the particle Froude number Fr in the central tube 3 p About 15. The microwave frequency used is about 2.45GHz.

[0057] The table below gives the basic process parameters.

[0058] raw material

[0059] Type Ground, dried and graded gold ore with approximately 5ppm gold

[0060] ≌5g / t

[0061] Particle fraction

[0062] μm 50

[0063] Composition wt%

[0064] Organic carbon 1.05

[0065] CaCO 3 19.3

[0066] Al 2 o 3 12.44

[0067] FeS 2 2.75

[0068] Inert substances such as SiO 2 64.46

[0069] Solid handling capacity, about t / h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com