Device for improving pipe and gas-solid circumfluence bed coupling reaction

The technology of a reaction device and a riser is applied in the directions of fluidized bed combustion equipment, lighting and heating equipment, combustion methods, etc., and can solve the problems that the riser is difficult to meet the reaction requirements, the storage capacity of the riser is difficult, and the particle residence time is short, etc. Achieve the effect of reducing resistance, improving stability, and uniform gas-solid contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

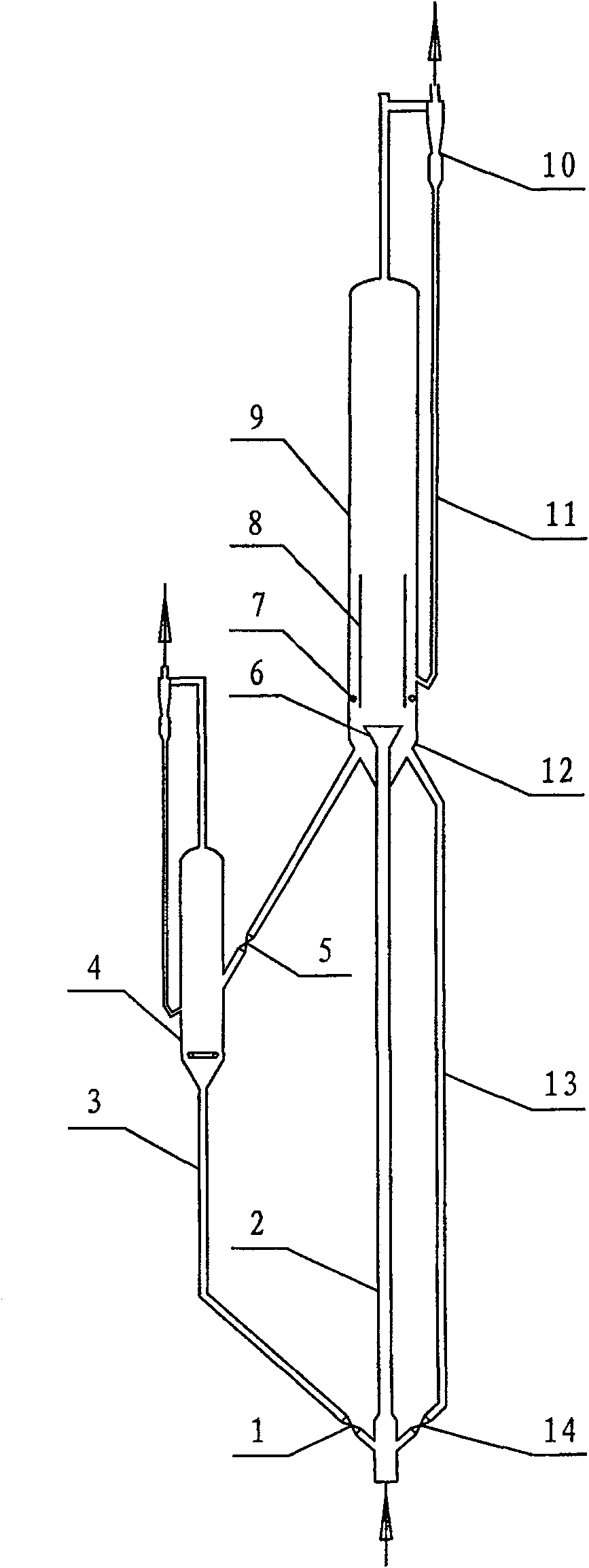

[0027] See attached figure 1 , the riser and gas-solid circulating bed coupling reaction device of the present embodiment include: riser 2, external circulation pipe 3, external circulation fluidized bed 4, shower head type distributor 6, annulus gas distribution ring 7, guide tube 8. Outer cylinder 9, gas-solid separator 10, material leg 11, inverted cone 12, internal circulation pipe 13 and control valves 1, 5 and 14. The outlet end of the riser pipe 2 extends into the inverted cone 12 at the lower part of the outer cylinder body 9 of the circulating bed, and the outlet end is connected with the shower head distributor 6, which is placed at the lower part of the outer cylinder body 9 of the circulating bed or the inverted cone 12 middle. The guide tube 8 adopts a single-section form and is placed above the shower head distributor 6. In order to ensure that the particles in the annular gap flow smoothly into the guide tube 8, and at the same time to make the particles in the...

Embodiment 2

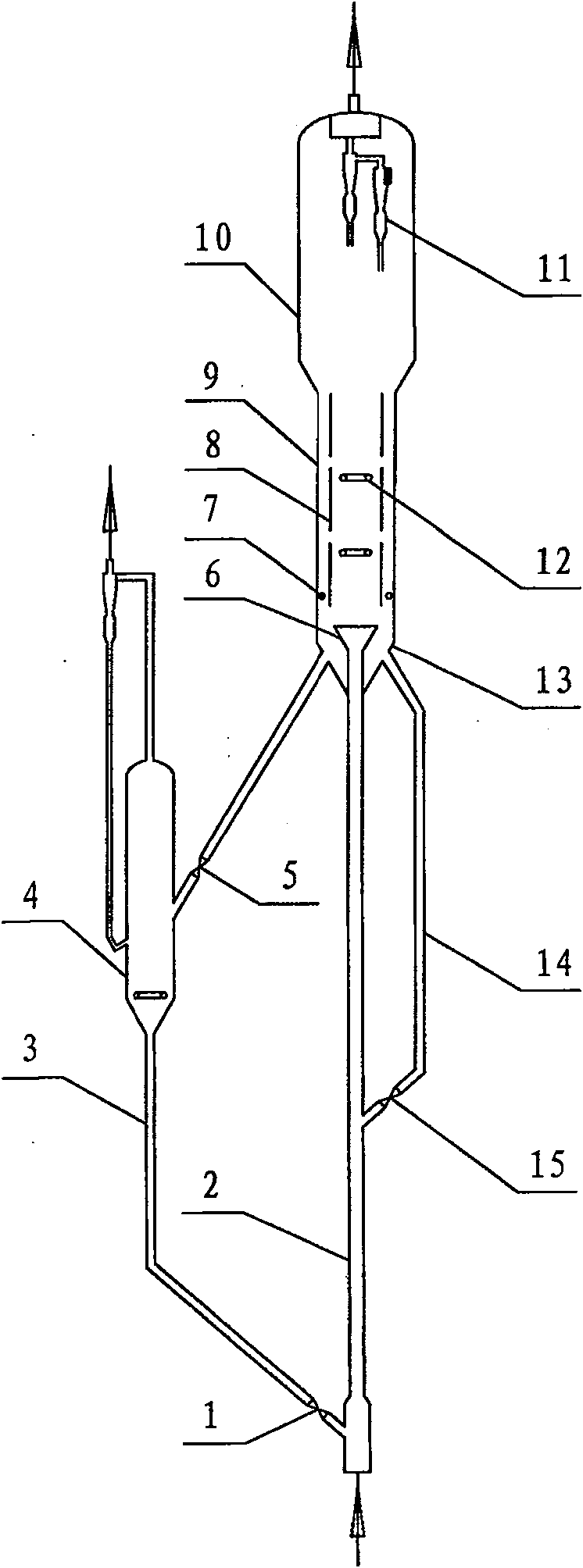

[0032] See attached figure 2 , the riser and gas-solid circulating bed coupling reaction device of the present embodiment include: riser 2, external circulation pipe 3, external circulation fluidized bed 4, shower head type distributor 6, annulus gas distribution ring 7, guide tube 8. Circulation bed outer cylinder 9, settling space outer cylinder 10, gas-solid separator 11, auxiliary gas distribution ring 12, inverted cone 13, internal circulation pipe 14 and control valves 1, 5 and 15. The outlet end of the riser pipe 2 extends into the inverted cone 13 at the lower part of the outer cylinder body 9 of the circulating bed, and the outlet end is connected with the shower head distributor 6, which is placed at the lower part of the outer cylinder body 9 of the circulating bed or the inverted cone 13 middle. The diversion cylinder 8 adopts an equal-diameter straight cylindrical multi-section diversion cylinder, which is placed above the shower head distributor 6. In order to ...

Embodiment 3

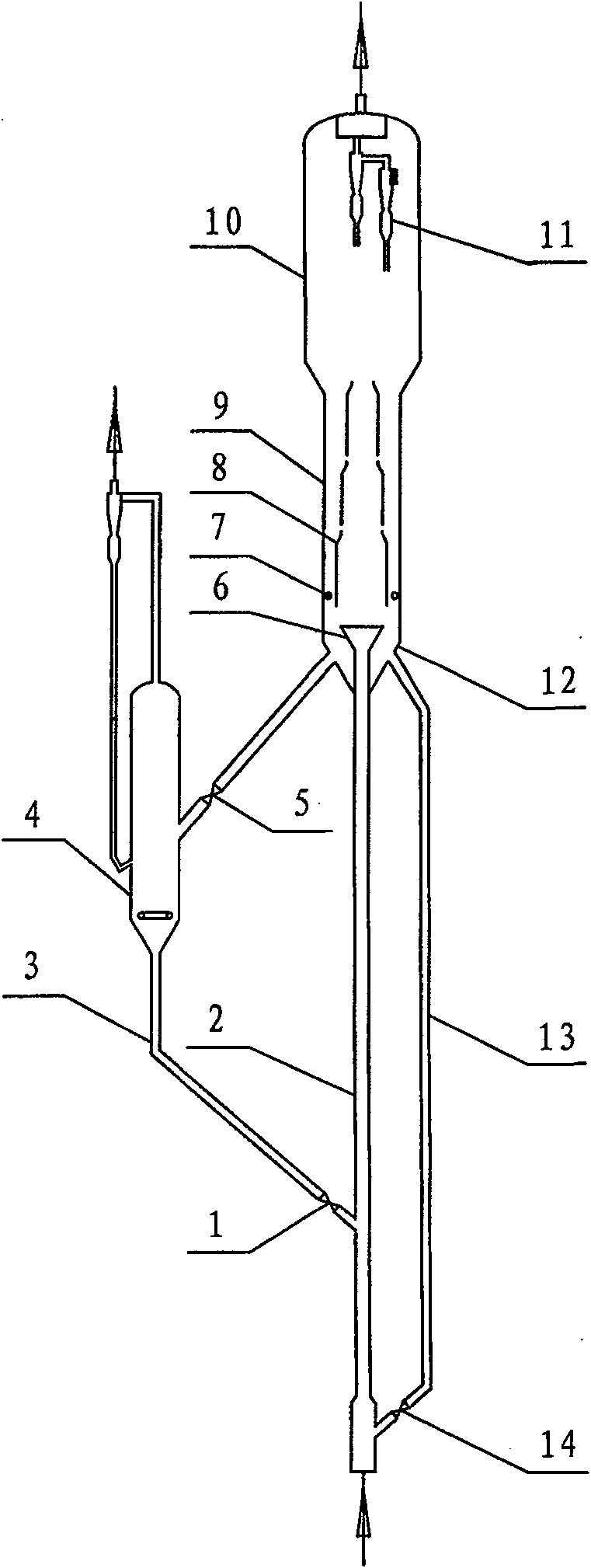

[0037] See attached image 3 , the riser and gas-solid circulating bed coupling reaction device of the present embodiment include: riser 2, external circulation pipe 3, external circulation fluidized bed 4, shower head type distributor 6, annulus gas distribution ring 7, guide tube 8. Circulation bed outer cylinder 9, settling space outer cylinder 10, gas-solid separator 11, inverted cone 12, internal circulation pipe 13 and control valves 1, 5 and 14. The outlet end of the riser pipe 2 extends into the inverted cone 12 at the lower part of the outer cylinder body 9 of the circulating bed, and the outlet end is connected with the shower head distributor 6, which is placed at the lower part of the outer cylinder body 9 of the circulating bed or the inverted cone 12 middle. The diversion cylinder 8 is a multi-section diversion cylinder with a reduced diameter straight cylinder, which is placed above the shower head distributor 6. In order to ensure that the particles in the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com