Ring-shaped fluidized bed reactor

A bed reactor and annular flow technology, applied in the field of annular fluidized bed reactors, can solve the problems of complex fluid mechanics, transfer phenomena, reducing the chance of gas-solid phase contact, cumbersome overall structure of the reactor, etc., and achieve effective use of heat sources. , The working state can be adjusted, and the effect of improving the reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

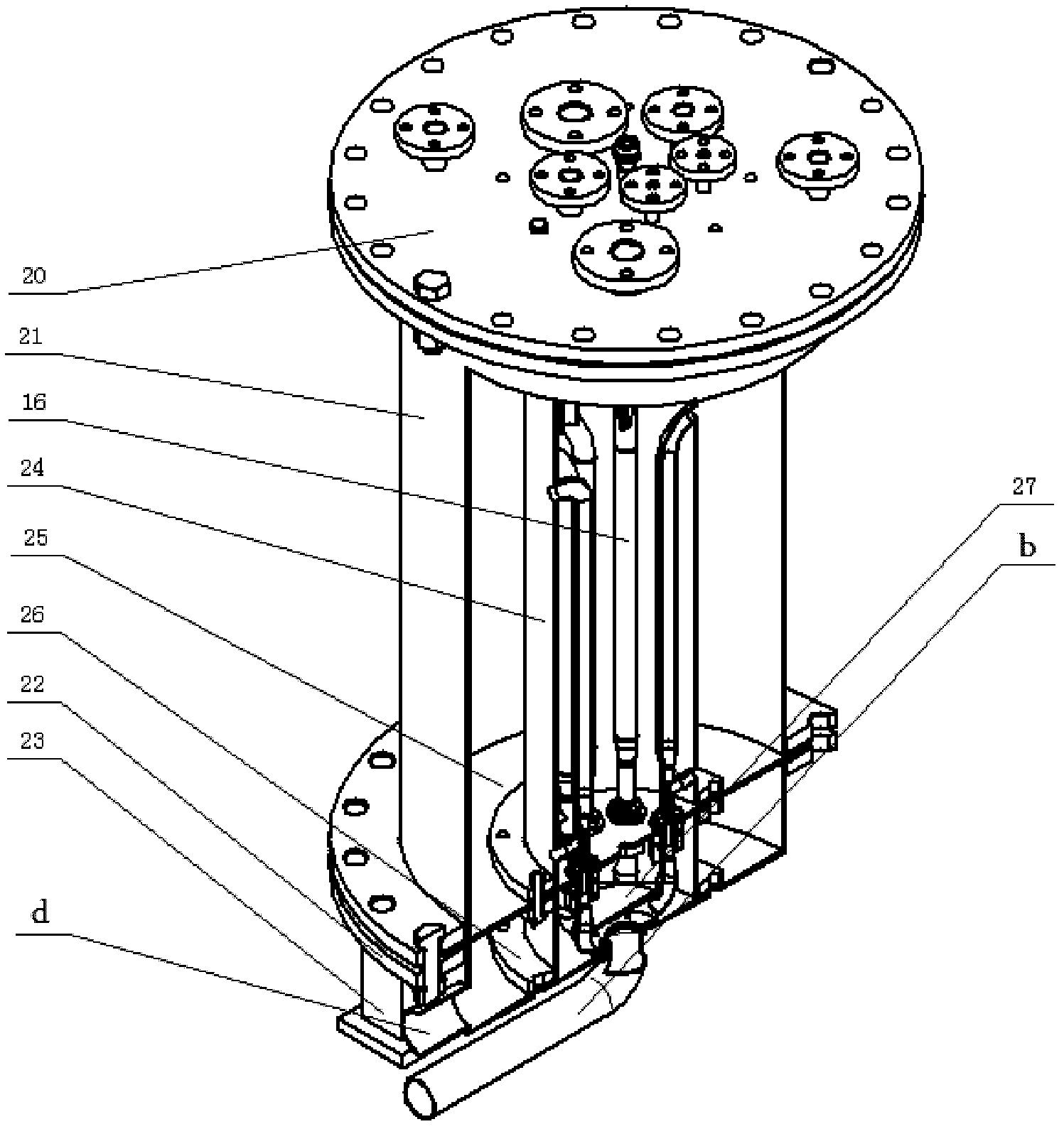

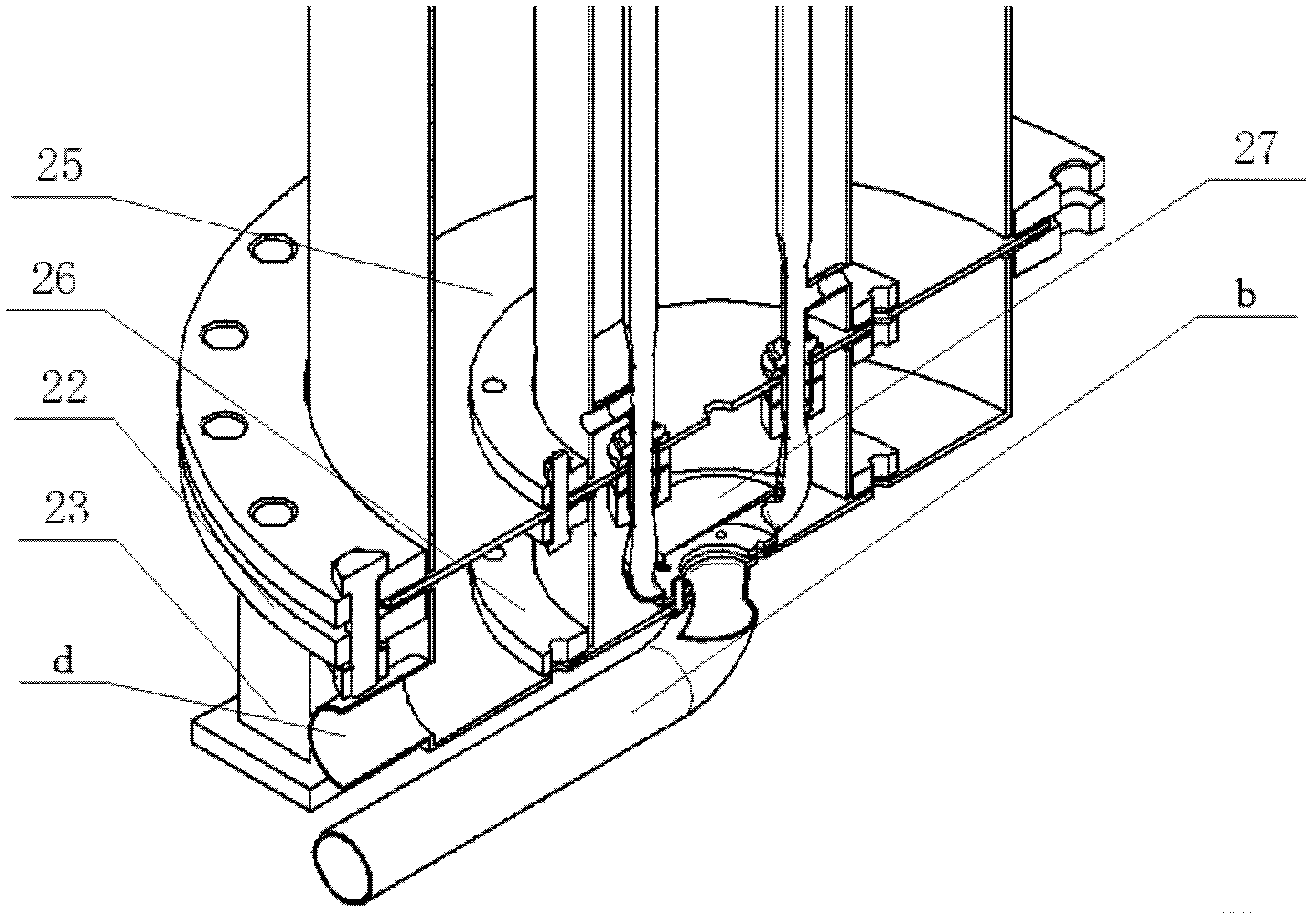

[0021] as attached figure 1 and attached figure 2 As shown, the present invention provides a kind of annular fluidized bed reactor, and this reactor comprises top cover 20, reactor shell 21, bottom shell 22, support 23, combustion chamber 24, air distribution plate 25, air distribution cabin Plate 26, gas distribution chamber 27 and circulation speed-increasing pipe 16, peripheral equipment includes cyclone separator (playing the role of gas-solid separation) and fan;

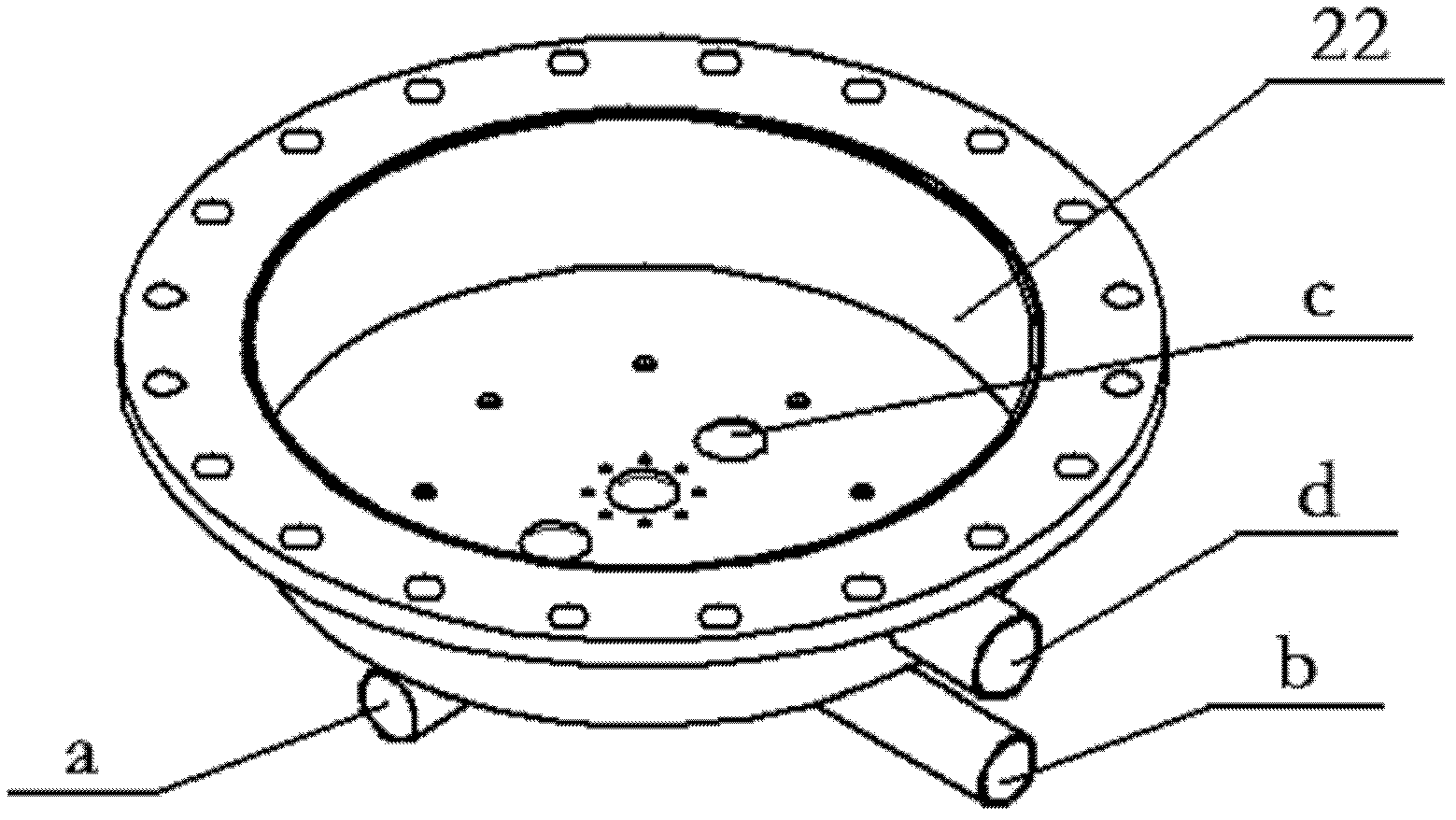

[0022] Wherein the reactor shell 21 is a cylindrical body with flanges welded at the upper and lower ends of the peripheral surface; the combustion chamber 24 is also a cylindrical body with flanges welded at the upper and lower ends of the peripheral surface, and eight Mounting holes; if attached image 3 As shown, the bottom shell 22 is a cylinder with a flange welded on the upper end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com