Device with an annular spouted fluidized bed and operating method therefor

A spouted fluidized bed and equipment technology, applied in the field of its reaction chamber, can solve the problems of low heat transfer and mass transfer efficiency, and reduce interaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0205] Example 1 is the one covered in the most detail. The rest of the embodiments will be described in detail by the extent of their differences from the apparatus and operation of the apparatus of Embodiment 1. It is hereby meant that the general principles of operation of similar devices are known and obvious to those skilled in the art, as well as the typical set of additional devices required to carry out a particular process in a similar device.

[0206] For the sake of obviousness, not all of the following embodiments include detailed descriptions of sets of known additional devices required by the claimed device. This means that these devices are known and obvious to a person skilled in the art.

[0207] It is also meant that additional equipment listed in any of the following embodiments may also be used in any of the other embodiments, even if not mentioned in the latter, the necessity of which will be apparent to a person skilled in the art.

[0208] The followin...

specific Embodiment

[0211] Example 1.

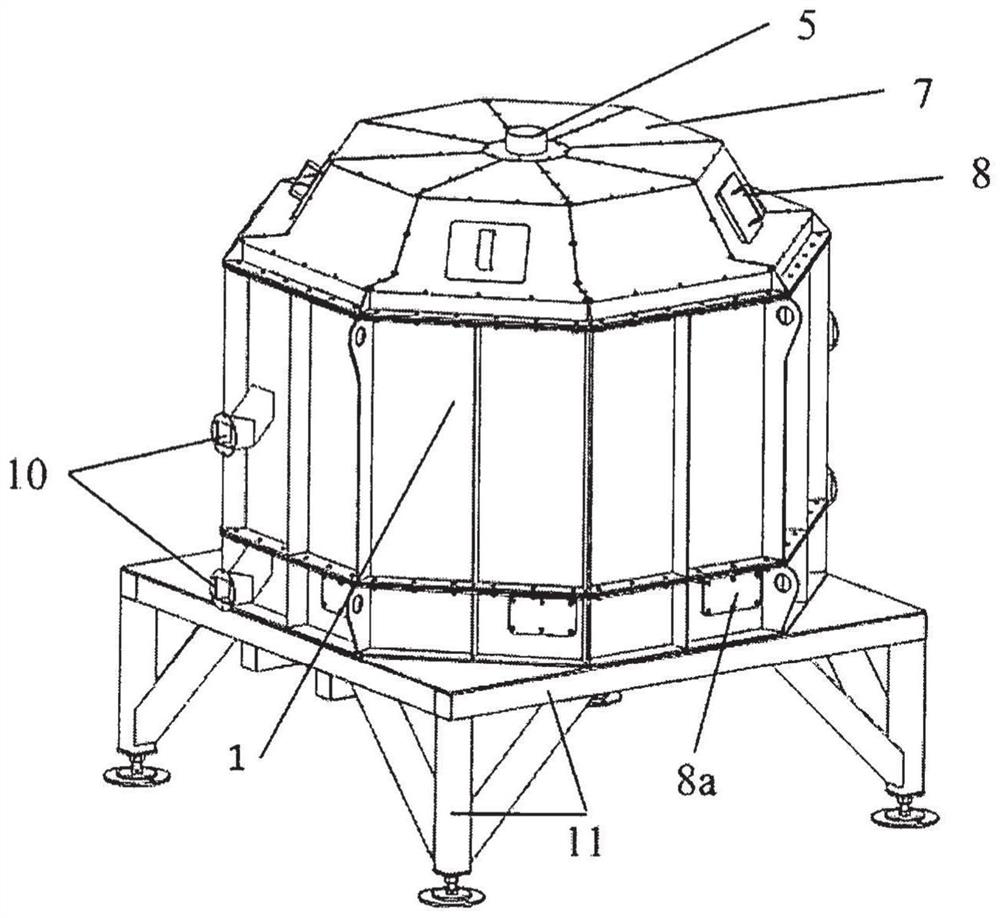

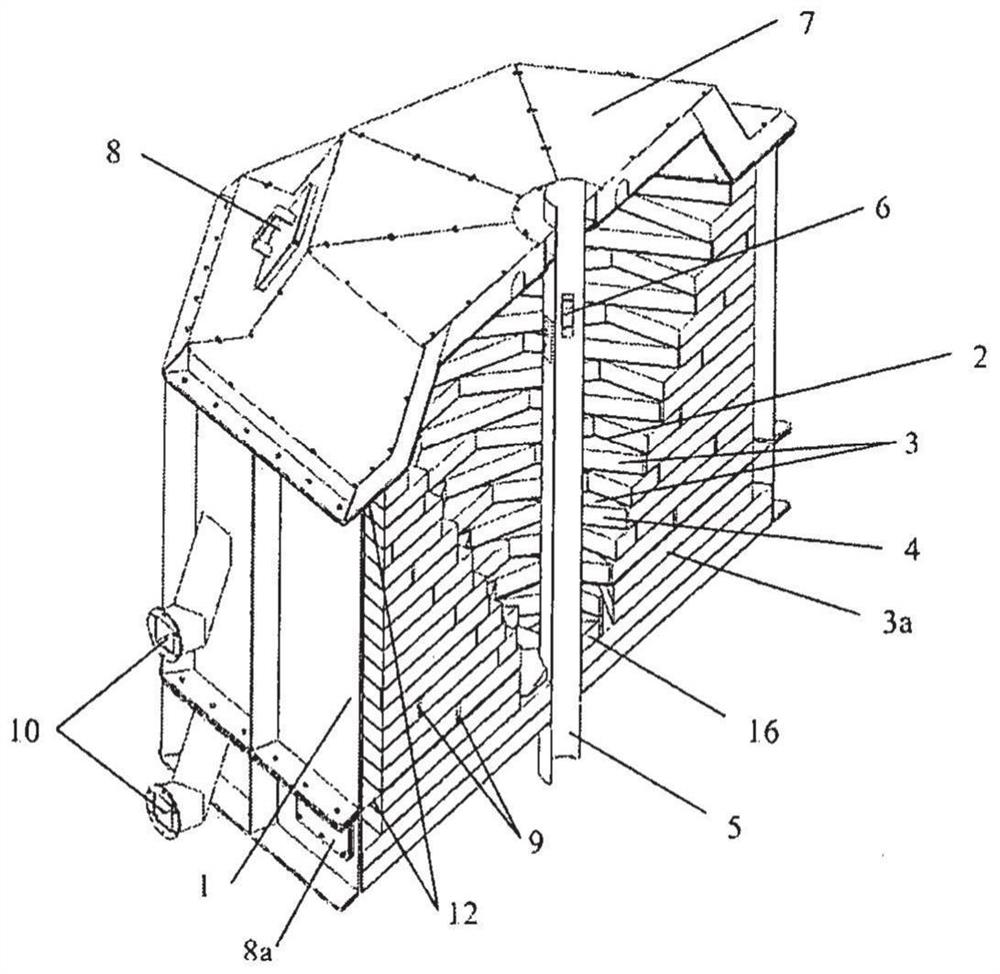

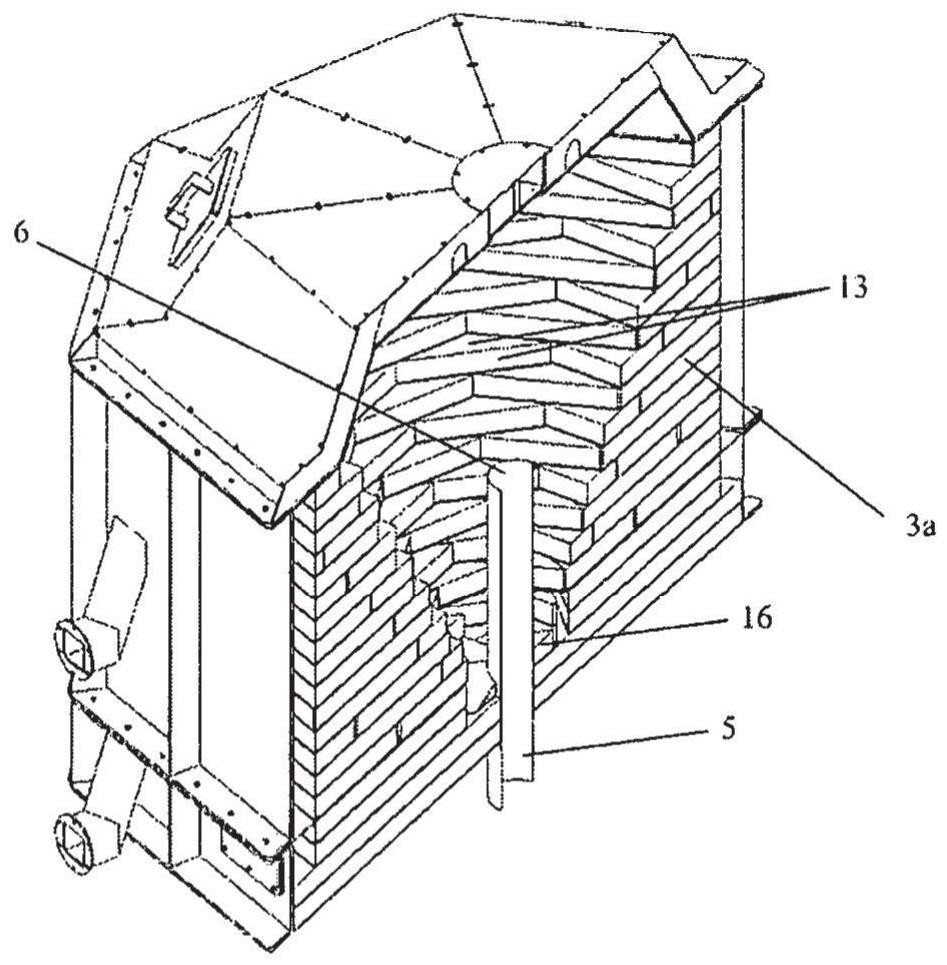

[0212] figure 1 , 1a The embodiments shown in and 2 can be used to obtain thermal energy by burning relatively large pieces of fuel, preferably of uniform composition and low bulk density, such as biofuel grains (pellets), wood chips and other similar types of fuels.

[0213] to connect to the figure 1 and 1a The list of peripherals in the equipment used to carry out the described procedure should include at least the following:

[0214] Fuel supply equipment known in the prior art to ensure an adjustable supply of fuel through one or more feed channels to the reaction chamber 2 via a flanged connection into the cover of the feed channel 8 connect;

[0215] Ignition (pilot) means known in the art, such as a pilot burner using liquid or gaseous fuel (remotely started and stopped by an automatic control system), is installed in channel 9 (leaving a gap) so that the Their channels 9 are supplied with sufficient oxidant (eg air) for operation and are co...

Embodiment 2

[0232] exist figure 1 and 1a The embodiment shown in can be used to burn finely divided or pulverized fuels such as sanding dust from furniture production, sawdust, fine peat, coal dust and other similar combustible materials. In this case, the claimed device should preferably be equipped with a lower feed mechanism for feeding the raw material (finely divided fuel). For this purpose, known feed mechanisms (eg screw feed, pneumatic conveying, etc.) are preferably mounted at the bottom of the device. For the installation of the feeding means, some channels 9 in the substructure 15 (near the bottom 17) can be utilized, or additional channels for installing (locating) the elements of the feeding mechanism should be provided in the substructure 15, through which the finely dispersed fuel passes is supplied to reaction chamber 2. Clearly, the channel 9 should have a shape and dimensions to accommodate said feed mechanism. A flange should also be located on the casing of the eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com