Standpipe inlet for enhancing particulate solids circulation for petrochemical and other processes

A standpipe and particle technology, applied in chemical instruments and methods, petroleum industry, chemical/physical processes, etc., can solve problems such as bubble inhalation and air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

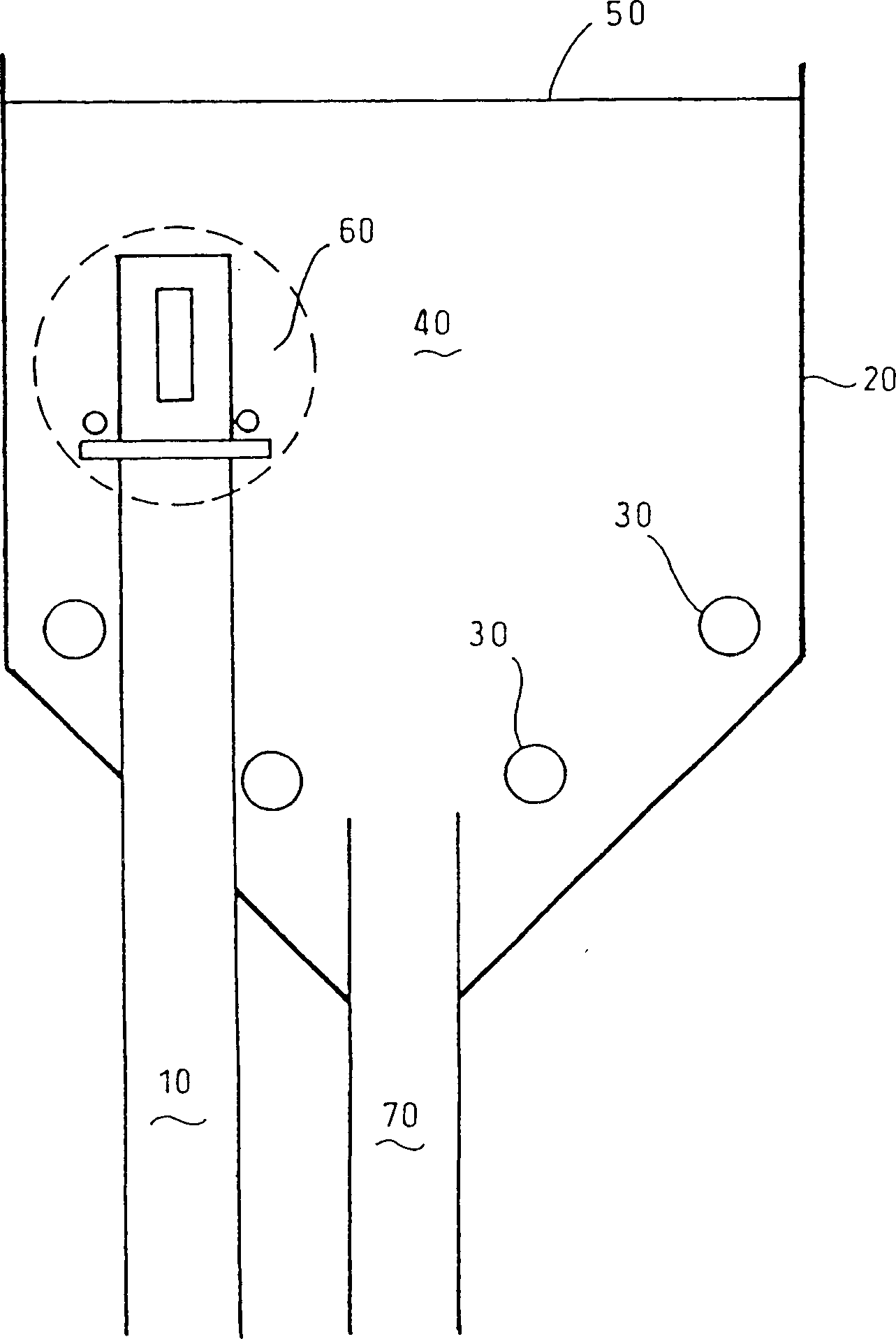

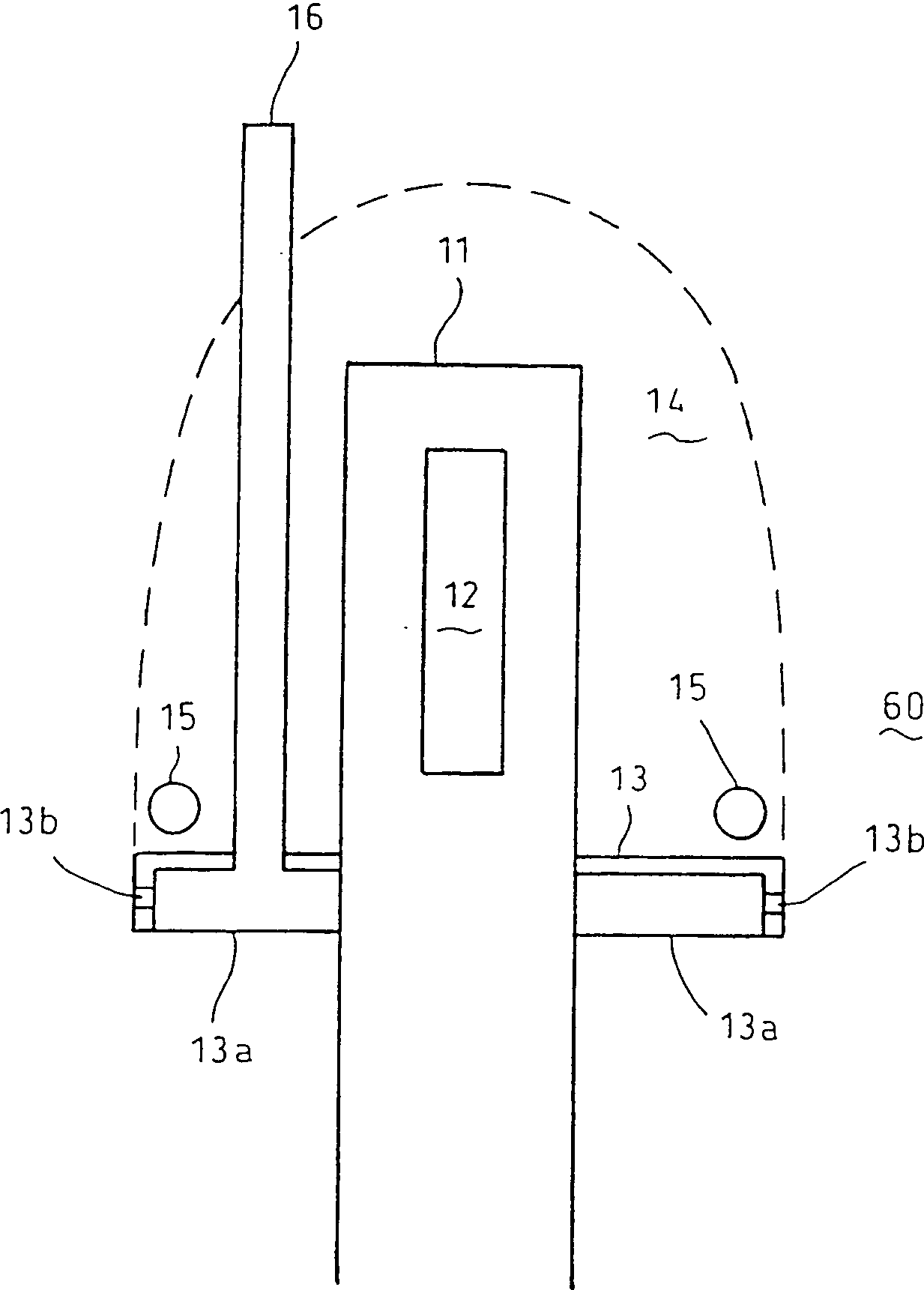

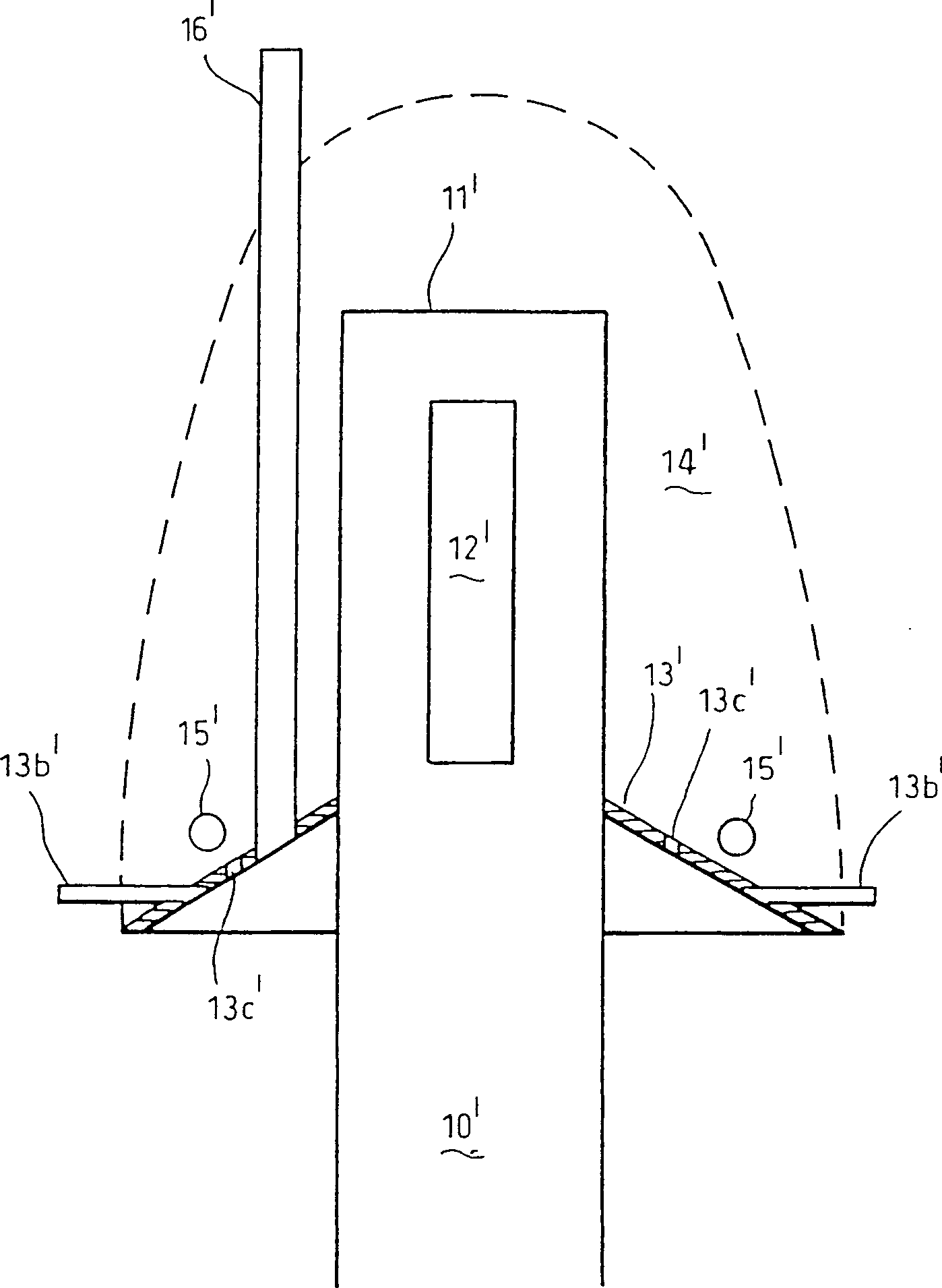

[0019] refer to figure 1 , figure 1 A cross-sectional view of the lower portion of a conventional regenerator vessel 20 of an FCC unit provided with a regenerator standpipe 10 including an inlet portion 60 for intake of regenerated catalyst according to the present invention. Spent catalyst is transported from the stripper (not shown) through a conventional residual catalyst transfer line 70 and into regenerator 20 where coke deposited on the catalyst is fed by the primary air grid. The air burns off. Air from the grid 30 and the resulting combustion gases rise through the regenerator to fluidize the catalyst within the fluidized bed 40 . Combustion gases and entrained regenerated catalyst are separated in the upper part of the regenerator by a cyclone (not shown). Combustion gases are exhausted from the upper part of the regenerator, and regenerated catalyst separated by a cyclone (not shown) is returned to the fluidized bed 40 . The typical density of the fluidized bed 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com