Zanjon type gas-lift stream-pull tridimensional circulation type integral co-construction oxidation ditch

A technology of three-dimensional circulation and oxidation ditch, which is applied in the direction of aerobic and anaerobic treatment, can solve problems such as non-linear increase of installed capacity and dynamic load, reduction of economic efficiency of deep ditch oxidation ditch, deterioration of natural water quality, etc., and achieve artificial Less requirements, good solid-liquid separation effect, easy automatic control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

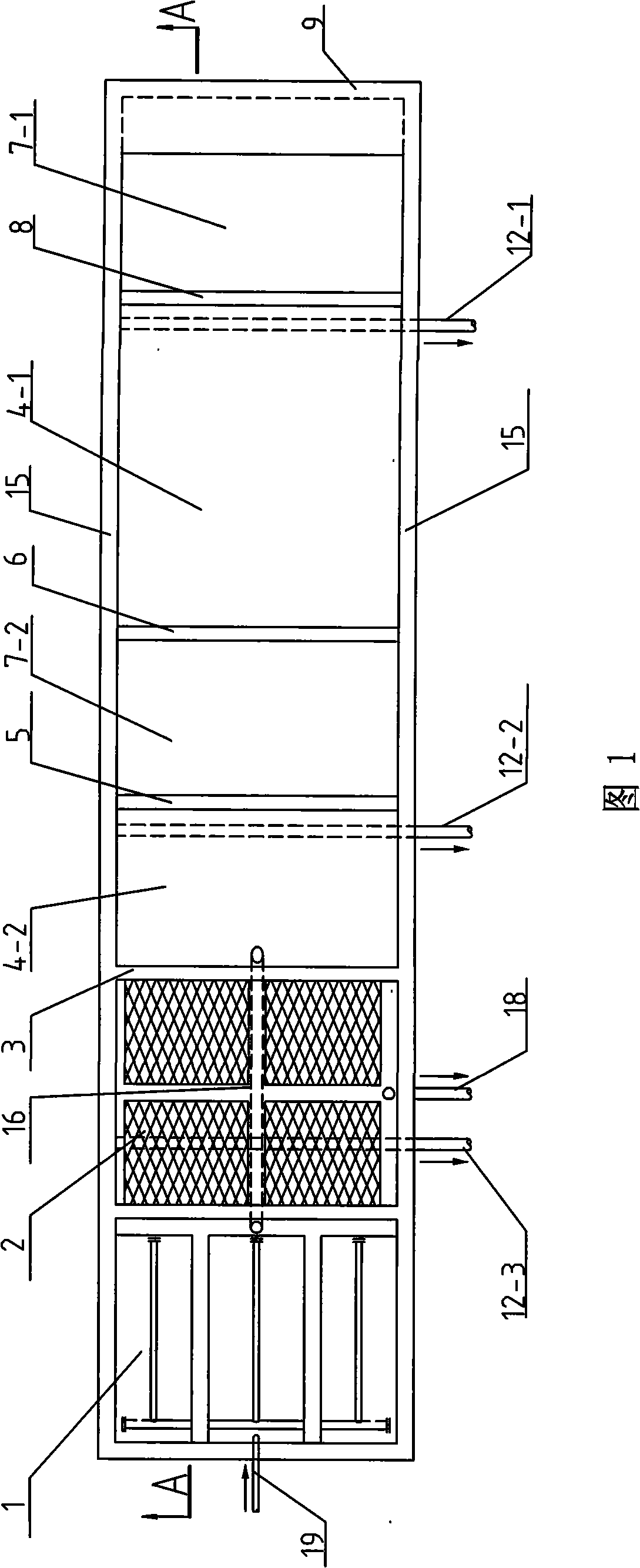

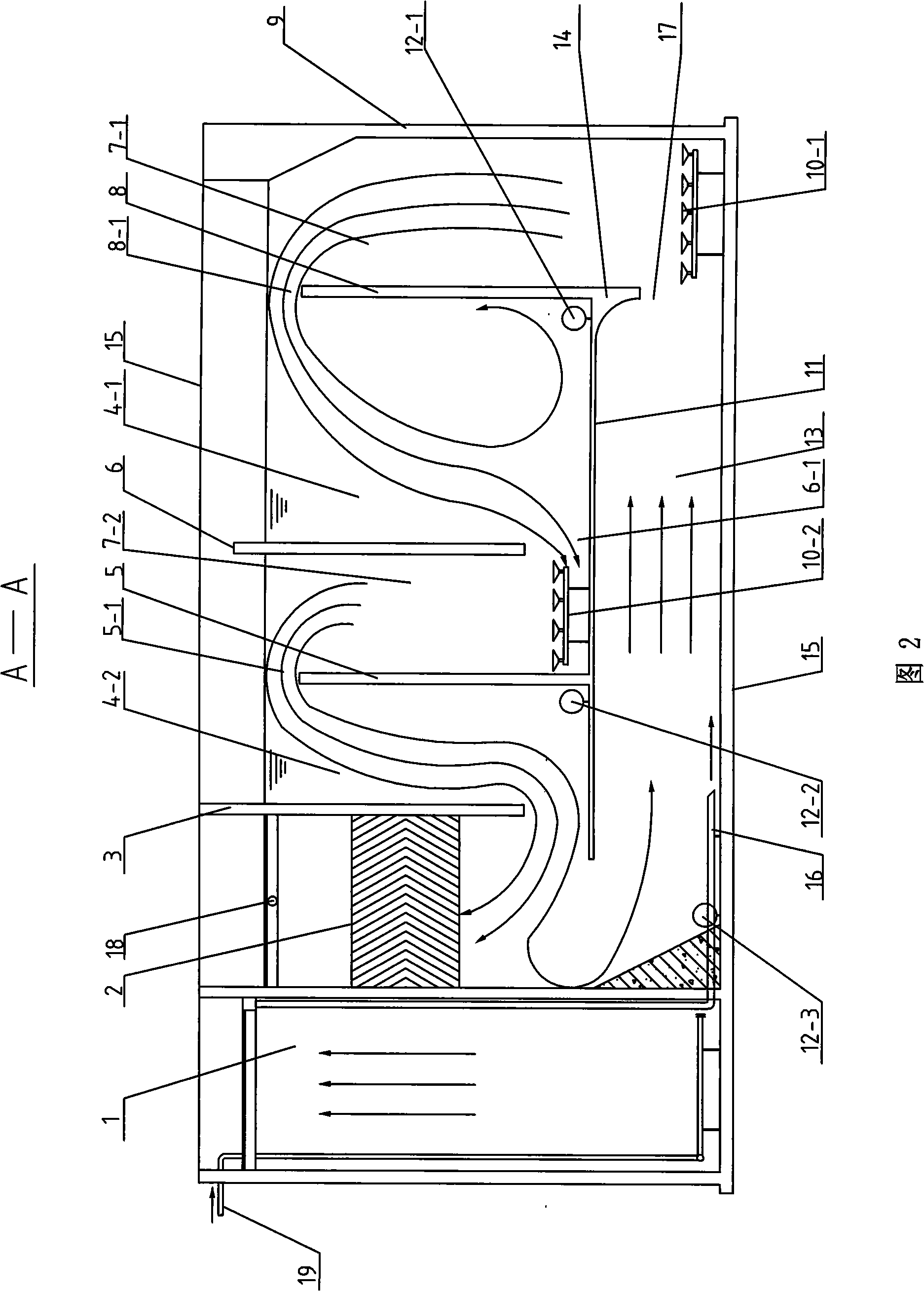

[0014] Fig. 1 is a schematic top view of the present invention; Fig. 2 is a sectional view of A-A of Fig. 1 . The arrows in the figure indicate the flow direction of sewage (waste) water and mixed liquid. As shown in the figure, it is a rectangular deep ditch air-lift push-flow three-dimensional circulation integrally built oxidation ditch, which is the same as the existing technology, including anaerobic area, anoxic area, aeration area, and microporous aeration area. The aerobic zone and the solid-liquid separation zone of the gas device group are combined to build an oxidation ditch, and the anaerobic zone is set at the front end of the main ditch, which is characterized in that it is in the middle of the ditch body between the anaerobic zone 1 and the end wall 9 at the end of the main ditch. The lower part is equipped with a horizontal partition 11 that divides the main channel into upper and lower channels and leaves channels at the front and rear; the aerobic zone is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com