Magnetic type recycling pyrolyzer for preparing biomass activated carbon

A technology of activated carbon and pyrolyzer, applied in the field of magnetic circulation pyrolyzer, can solve the problems of low energy utilization efficiency, complex structure and high energy consumption, and achieve the advantages of improving equipment processing capacity, saving energy and reducing production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

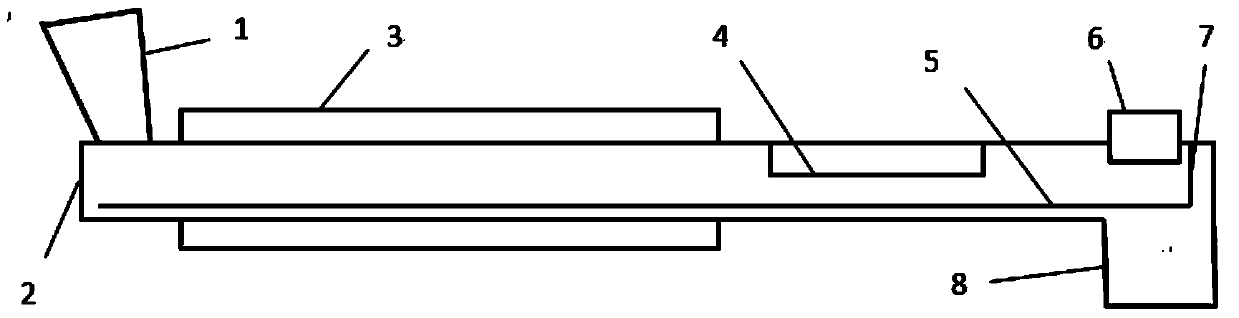

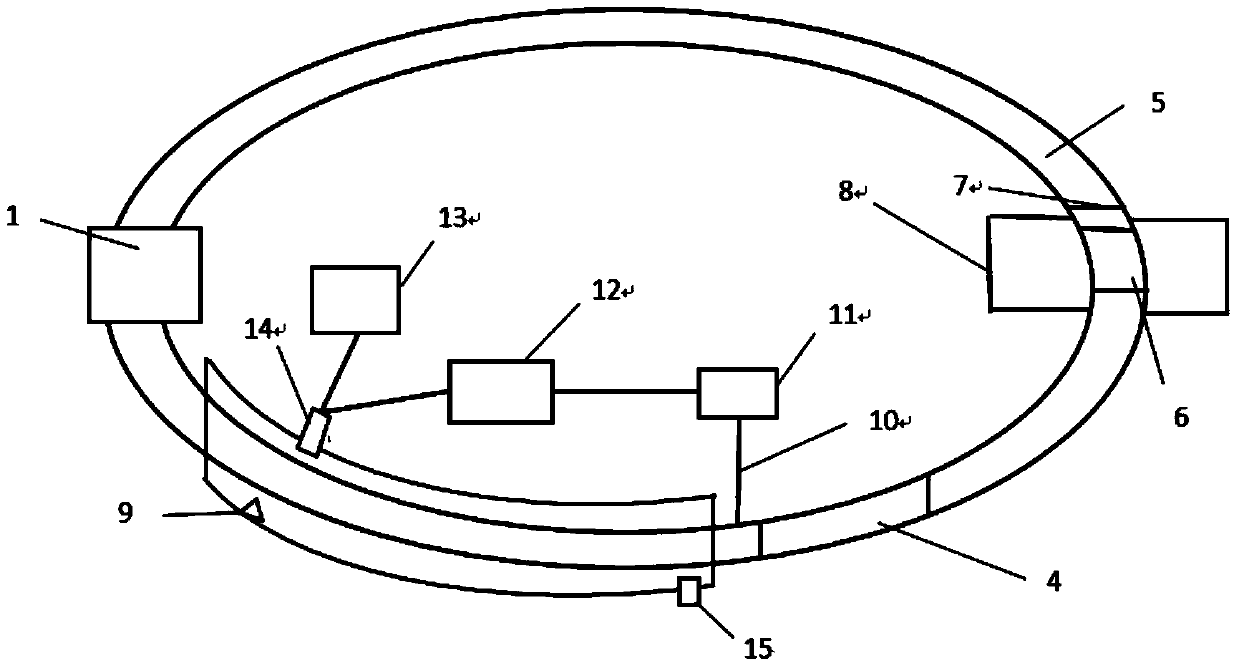

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] A magnetic circulating pyrolyzer for preparing biomass activated carbon, using a circular pipe with a rectangular cross section, laying a conveyor belt at the bottom to transfer biomass rice husks mixed with iron-based catalysis, and the rice husks pass through during the transfer process The combustion chamber outside the pipeline is thus pyrolyzed, and then the gas in the pyrolysis product is sucked away by the air pump, and after passing through the cyclone separator, the remaining gas is mixed with air and injected into the combustion chamber, where it is burned to realize energy recycling. The solid product passes through the part where the magnet is placed on the top, and the iron-based catalyst is recovered by the magnet, and the remaining solid is blocked by the baffle, and blown down by the fan at the top to the ash tank at the lower part.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com