Method for obtaining sludge pyrolytic oil with different uses in circulating fluidized bed reactor

A circulating fluidized bed and reactor technology, applied in pyrolysis treatment of sludge, petroleum industry, by-product vaporization, etc., can solve the problem of reducing the output of high calorific value component oil, and achieve the effect of improving the effect of gas-solid heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

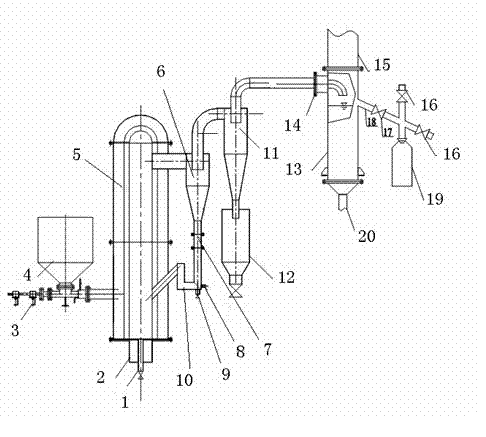

[0023] Refer below figure 1 , to specifically illustrate the present invention.

[0024] A method for obtaining sludge pyrolysis oil for different purposes in a circulating fluidized bed reactor. The method uses an adjustable rate circulating fluidized bed as the reactor for pyrolyzing sludge, and the high solid circulation rate is maintained at 30-50. The low solid circulation ratio is kept at 1-29; the solid circulation ratio of the circulating fluidized bed is controlled by adjusting the opening frequency and opening time of the slagging valve of the adjustable ratio circulating fluidized bed. details as follows:

[0025] 1) The sludge enters from the bottom side of the adjustable rate circulating fluidized bed, and the fluidization air enters through the bottom air chamber of the adjustable rate circulating fluidized bed. The adjustable rate circulating fluidized bed includes furnace slag discharge pipe 1, air chamber 2, Feeding screw 3, sludge silo 4, circulating fluidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com