Method for pyrolyzing municipal sludge and preparing biological oil and active carbon simultaneously

A technology of low-temperature pyrolysis and municipal sludge, which is applied in the fields of pyrolysis treatment of sludge, petroleum industry, by-product vaporization, etc. It can solve the problems of high cost and obtain single resource products, so as to improve quality and reduce residence time , the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

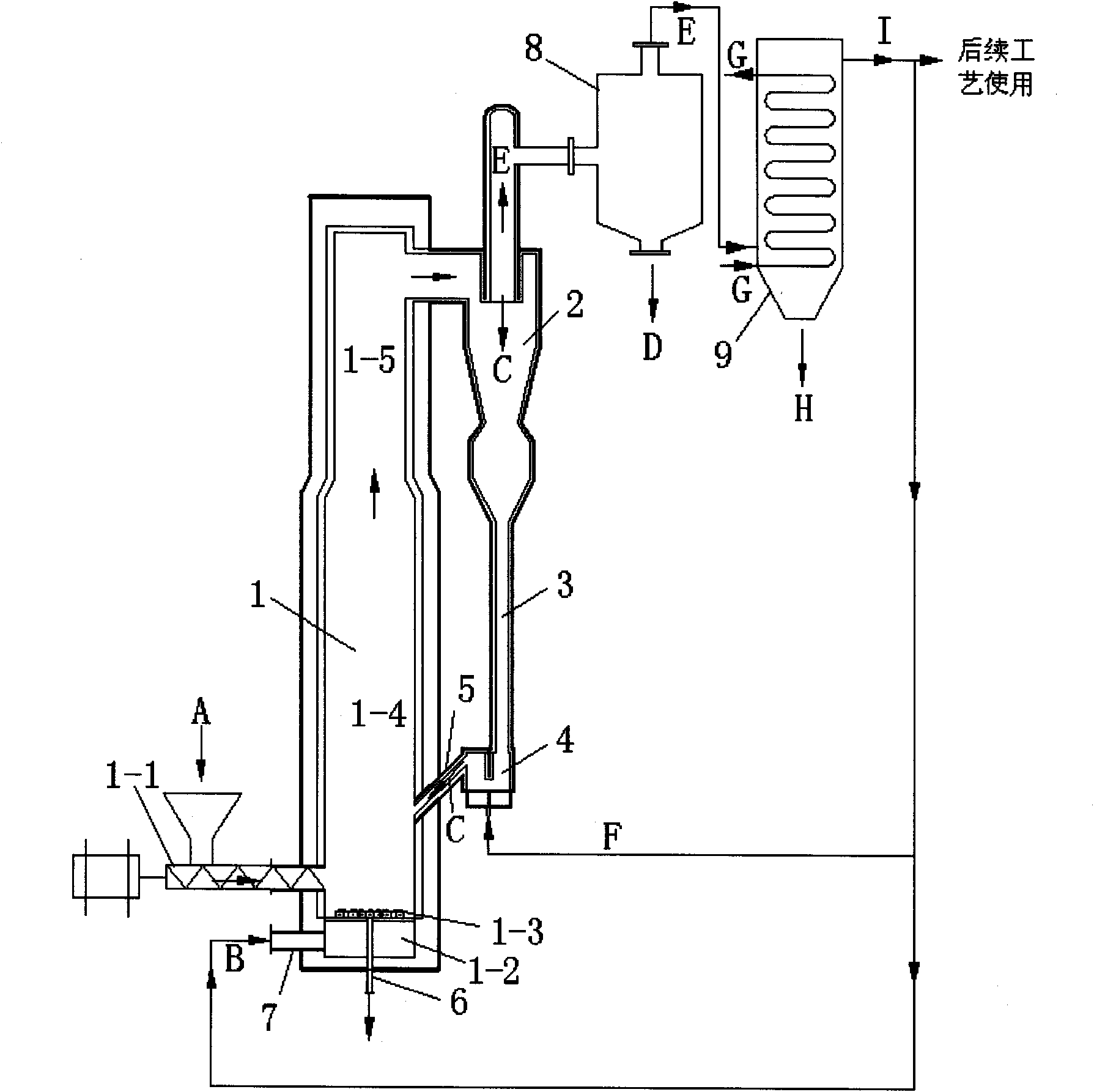

[0022] The device of the present invention is mainly composed of a pyrolysis reactor 1, a cyclone separator 2, a feeder 4, a ceramic filter 8 and a condenser 9.

[0023] The sludge A is fed into the turbulent fluidization zone 1-4 of the pyrolysis reactor 1 through the screw feeder 1-1. The average particle size of dry sludge in the turbulent fluidization zone is 0.5-1mm, the average particle size of the bed material is 1-2mm, the particle volume density is 0.3-0.4, the material layer height is 1-2m, the temperature is 400-500°C, and the gas velocity is 1-1.5 m / s. A slagging pipe 6 is provided at the bottom of the pyrolysis reactor 1 . The fluidizing wind B enters the air chamber 1-2 through the air inlet 7, and enters the turbulent fluidizing zone 1-4 after being rectified by the air distribution plate 1-3. Sludge A rapidly heats up in the anoxic environment in the turbulent fluidization zone 1-4 to form pyrolytic charcoal C and pyrolysis gas E, and enters the rapid flow zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com