Device for obtaining sludge pyrolysis oil of different purposes in circulating fluidized bed reactor

A circulating fluidized bed and reactor technology, which is applied in the pyrolysis treatment of sludge, petroleum industry, by-product vaporization, etc., can solve the problems of reducing oil production of high calorific value components, and achieve the effect of improving gas-solid heat transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

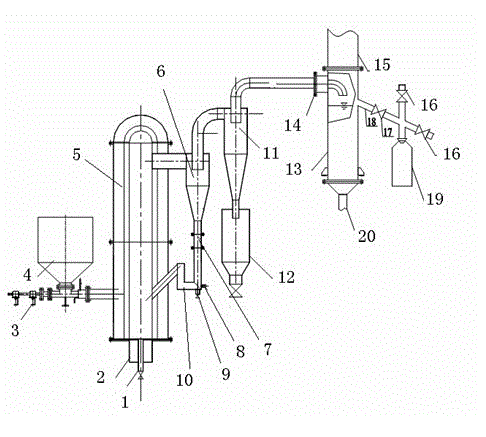

[0018] Refer below figure 1 , to specifically illustrate the present invention.

[0019] A device for obtaining sludge pyrolysis oil for different purposes in a circulating fluidized bed reactor, including a furnace slagging pipe 1, an air chamber 2, a feeding screw 3, a sludge silo 4, a circulating fluidized bed body 5, and a second First-stage cyclone separator 6, expansion joint 7, loose air pipe 8, feeder slagging valve 9, feeder 10, second-stage cyclone separator 11, carbon residue storage tank 12, spray tower liquid storage section 13 , spray tower air inlet 14, spray tower main body 15, upper oil dredging valve 16, upper oil oil collection pipeline valve 17, upper oil oil collection pipeline 18, upper oil oil collection bottle 19, lower oil discharge port 20. The sludge silo is connected to the lower end of the circulating fluidized bed body through a feeding screw, the first-stage cyclone separator is connected to the upper part of the circulating fluidized bed body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com