Pyrolysis and combustion coupled circular reaction method and device

A combustion cycle and reaction device technology, used in the production of combustible gas, direct heating and dry distillation, preparation of liquid hydrocarbon mixtures, etc. The effect of large production capacity of equipment, small heat loss of equipment and enhanced pyrolysis capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

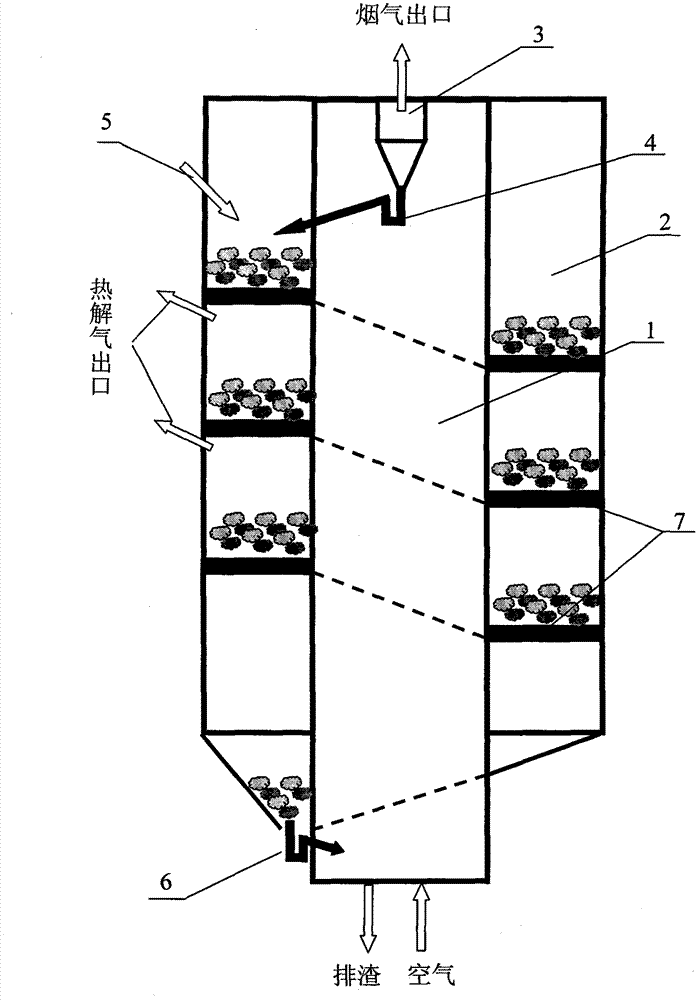

[0041] The pyrolysis coupled combustion cycle reaction device is an integrated device with a double sleeve structure in which the inner cylinder is a combustion chamber. figure 1 As shown, it includes: feeding mechanism 5, fluidized bed combustion chamber 1, pyrolysis chamber 2, gas-solid separation mechanism 3, flue gas outlet, upper feeding mechanism 4, lower feeding mechanism 6, pyrolysis gas outlet, air inlet and the slag outlet, wherein the fluidized bed combustion chamber 1 is the inner cylinder of the device, the annular space between the inner cylinder and the outer cylinder is the pyrolysis chamber 2, and the upper part of the fluidized bed combustion chamber 1 is provided with a gas-solid separation mechanism 3, and its gas phase The outlet is connected to the flue gas outlet, and its solid phase outlet is connected to the upper part of the pyrolysis chamber through the upper feeding mechanism 4. The upper part of the pyrolysis chamber is provided with a feeding mecha...

Embodiment 2

[0044] This embodiment is an improved device of embodiment 1, such as figure 1 As shown, except that a spirally descending plate structure guide member 7 is set in the pyrolysis chamber 2, the remaining parts are the same as in Embodiment 1. One side of the guide member is connected with the wall surface of the fluidized bed combustion chamber, and the other side is connected with the wall surface of the pyrolysis chamber.

[0045] In this embodiment, since the flow guide member 7 connected with the high-temperature wall of the fluidized bed combustion chamber is arranged in the pyrolysis chamber, the following beneficial effects will be produced: 1. The wall of the pyrolysis chamber constitutes the solid flow channel. Because the flow guide member has good thermal conductivity, these three walls are in a high temperature state, which strengthens the indirect heating process of the solid material in the pyrolysis chamber; The height of the solid material in the above-mentione...

Embodiment 3

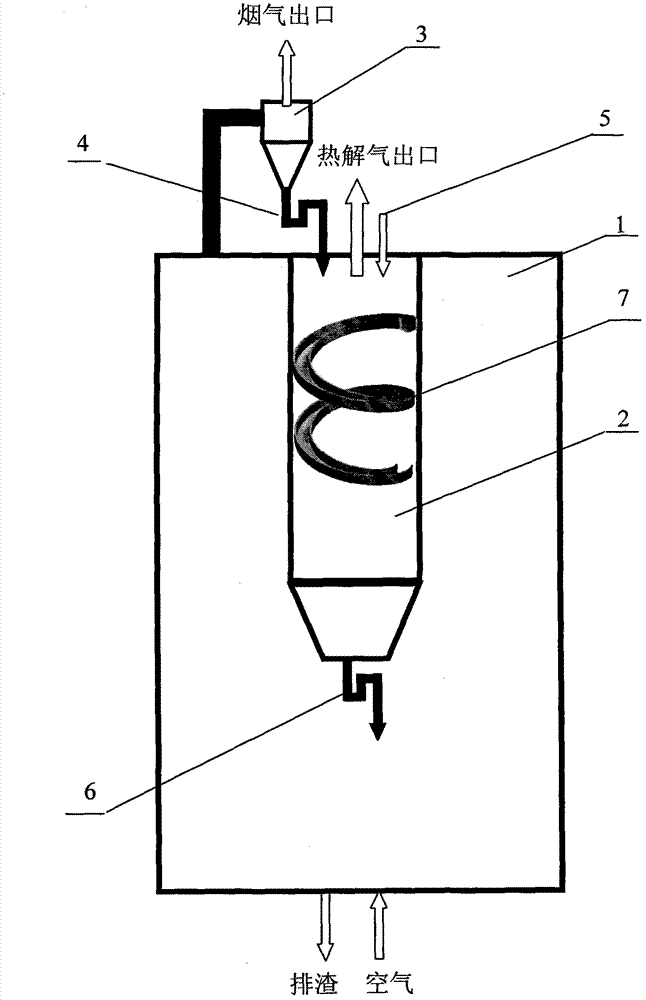

[0047] The pyrolysis coupled combustion cycle reaction device is an integrated device with a double-sleeve structure whose inner cylinder is a pyrolysis chamber, such as figure 2 As shown, it includes: feeding mechanism 5, fluidized bed combustion chamber 1, pyrolysis chamber 2, gas-solid separation mechanism 3, flue gas outlet, upper feeding mechanism 4, lower feeding mechanism 6, pyrolysis gas outlet, air inlet and the ash outlet, wherein the pyrolysis chamber 2 is the inner cylinder of the device, the annular space between the inner cylinder and the outer cylinder is the fluidized bed combustion chamber 1, and the upper part of the fluidized bed combustion chamber 1 is provided with a gas-solid separation mechanism 3, and its inlet It is connected to the fluidized bed combustion chamber, its gas phase outlet is connected to the flue gas outlet, and its solid phase outlet is connected to the upper part of the pyrolysis chamber through the upper feeding mechanism 4. The pyrol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com