Solid heat carrier furnace with controllable solid circulation amount in anaerobic pyrolysis environment

A technology of solid heat carrier and circulating volume, applied in coke ovens, direct heating dry distillation, special form dry distillation, etc., can solve problems such as low accuracy of returning material, system failure, and hindering the development of solid heat carrier pyrolysis domestic waste technology, etc. To achieve the effect of anaerobic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

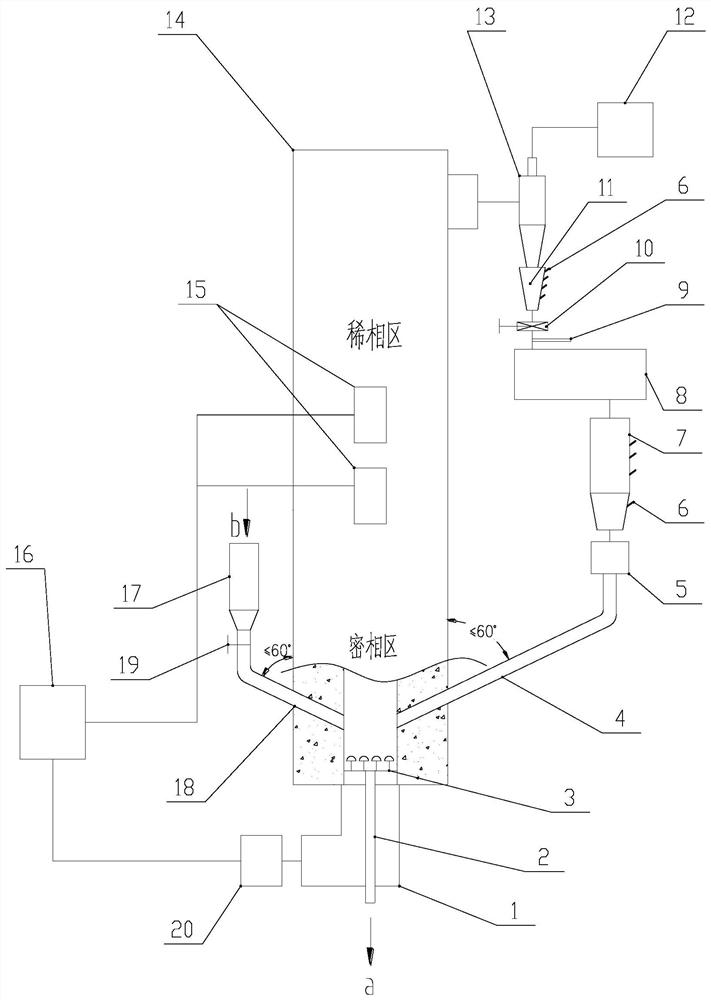

[0030] A solid heat carrier furnace with controllable solid circulation in an anaerobic pyrolysis environment, comprising a furnace body 14, a slag discharge pipe 2 and an air distribution device 3 are arranged at the bottom of the furnace body 14. Heat carrier feeding equipment 17 is arranged on the back wall of the furnace body 14 , and the lower part of the heat carrier feeding device 17 is provided with a feeding control valve 19 and a feeding inclined pipe 18 , and the feeding inclined pipe 18 is connected with the furnace body 14 . The top front wall of the furnace body 14 is connected with the cyclone separator 13 . The lower part of the cyclone separator 13 is sequentially connected with the buffer bin 11, the feeding controller 10, the solid flow meter 9, the reactor 8, the intermediate bin 7, the feeding equipment 5, and the feeding pipe 4, and the feeding pipe 4 is connected with the furnace body 14 , forming a circulation channel for the solid heat carrier circuit....

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com