Method for carrying out gas-solid fluidized bed reaction

A fluidized bed reactor and circulating fluidized bed technology, applied in chemical instruments and methods, chemical recovery, organic chemistry, etc., can solve the problems of increasing separation costs and solid waste treatment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

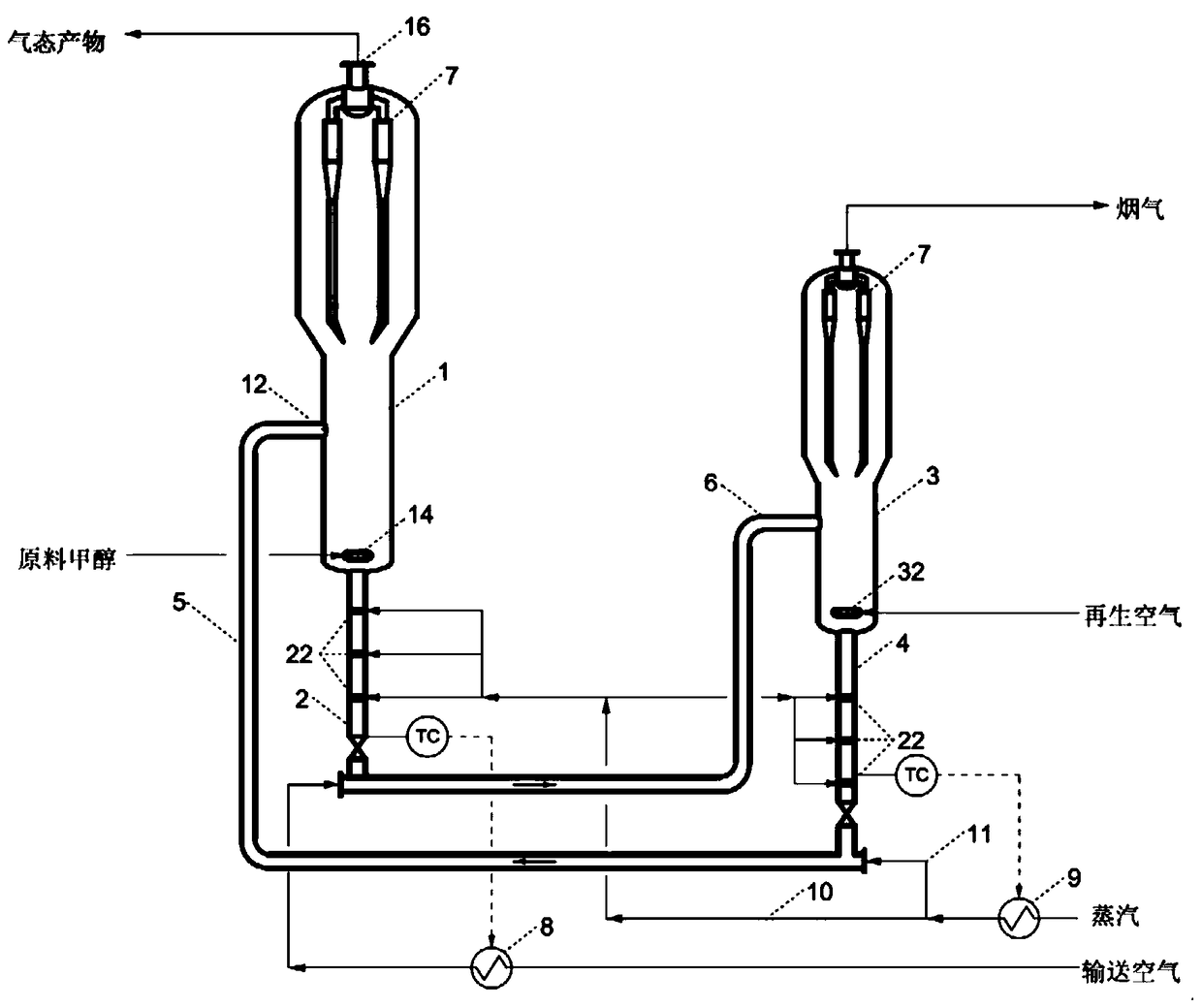

[0071] In this example, according to figure 1 The reaction system is constructed in the manner shown, wherein the volume of the fluidized bed reactor 1 is 100m 3 , The volume of the regenerator is 30m 3 , The stripping section of the raw catalyst and the stripping section of the regenerated catalyst have a diameter of 0.85m and a length of 5 meters, and the inner diameter of the raw delivery pipe and the regenerated delivery pipe is 0.50m and a length of 25m. The catalyst used in the present invention is the ZSM-5 catalyst synthesized according to the embodiment 1 method of Chinese patent application number CN104069888A patent literature, particle size is 10~120 μ m, average particle diameter 75 μ m, catalyzer once loading capacity 240 tons, catalyst circulation 2.4 tons / Time.

[0072] The raw material used is a mixed gas of methanol and water vapor with a mass ratio of 0.35, the temperature of the mixed gas is 510°C, the pressure is 0.12MPa, and the mass space velocity cal...

Embodiment 2

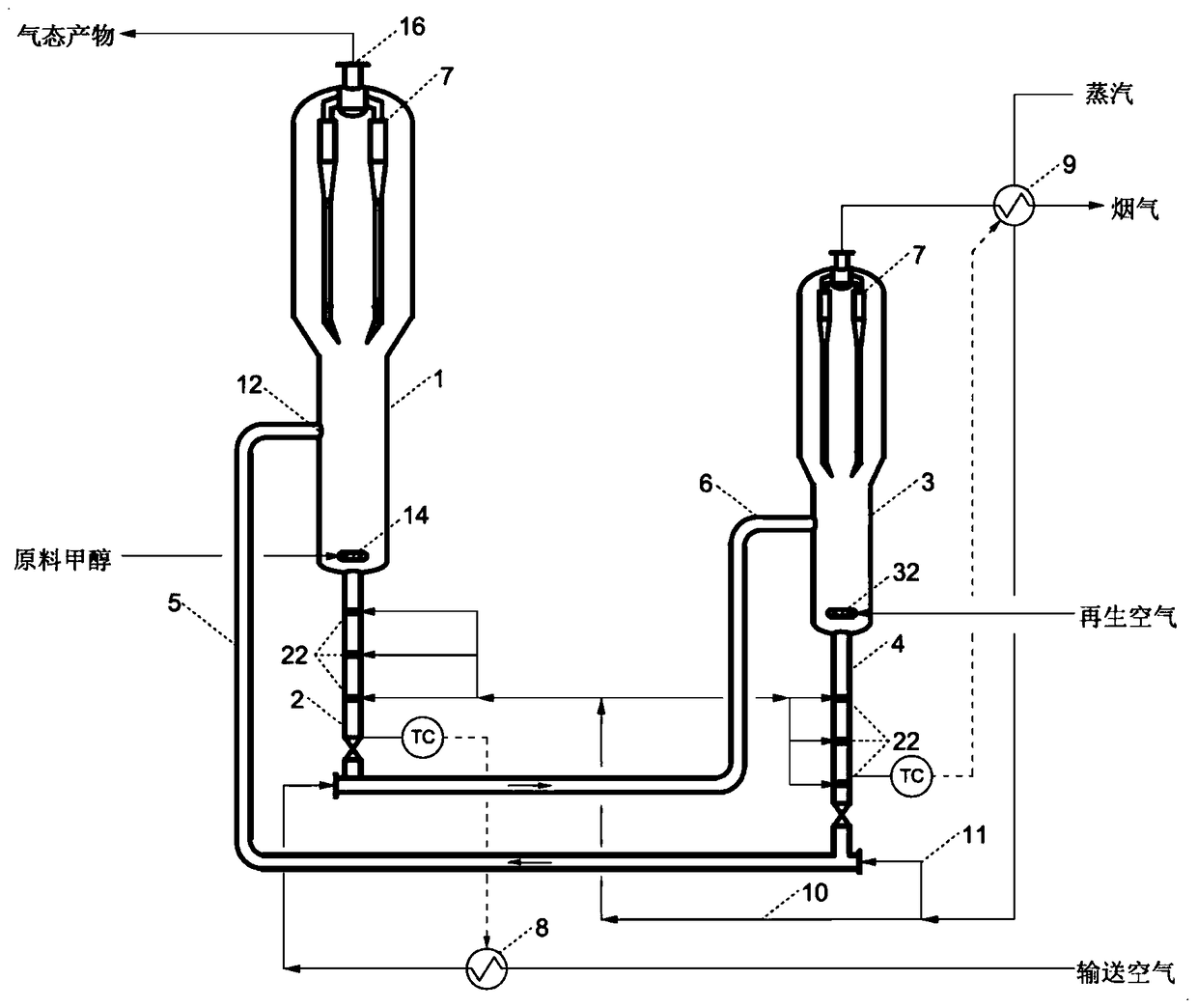

[0076] In this example, according to figure 2 The reaction system was constructed in the manner shown, and the conditions of Example 2 were the same as those of Example 1 except that the heating mode of the steam heater 9 was different. The difference is that the heat source of the steam heater 9 is provided by high-temperature flue gas, and the heating capacity of the heater is controlled by the temperature of the regenerative stripping section, so that the temperature of the heated steam reaches 475°C.

[0077] In this embodiment, the temperature difference between the gas and the contacting catalyst is less than 50° C., under this condition, the wear of the catalyst is 0.0252% / h, and 97.9 tons of catalyst can be saved every year. See Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com