Stock control method based on optimum replenishment period of spare part

A technology of inventory control and spare parts, applied in the field of warehouse management, can solve problems such as shortage of spare parts, chaotic management, backlog of spare parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

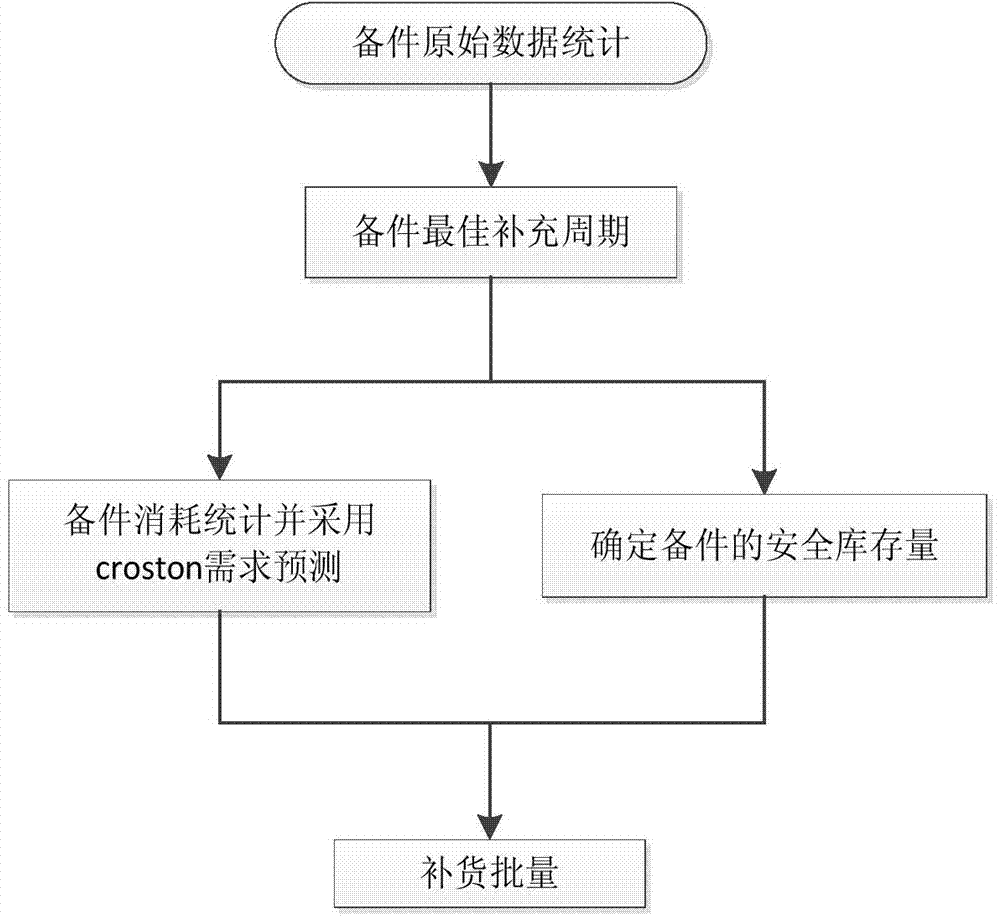

[0020] Establish an inventory control process and build an inventory control model, including:

[0021] Step 1) Calculate the total cost W in the replenishment cycle;

[0022] Among them, the total cost W in the replenishment cycle is calculated, specifically:

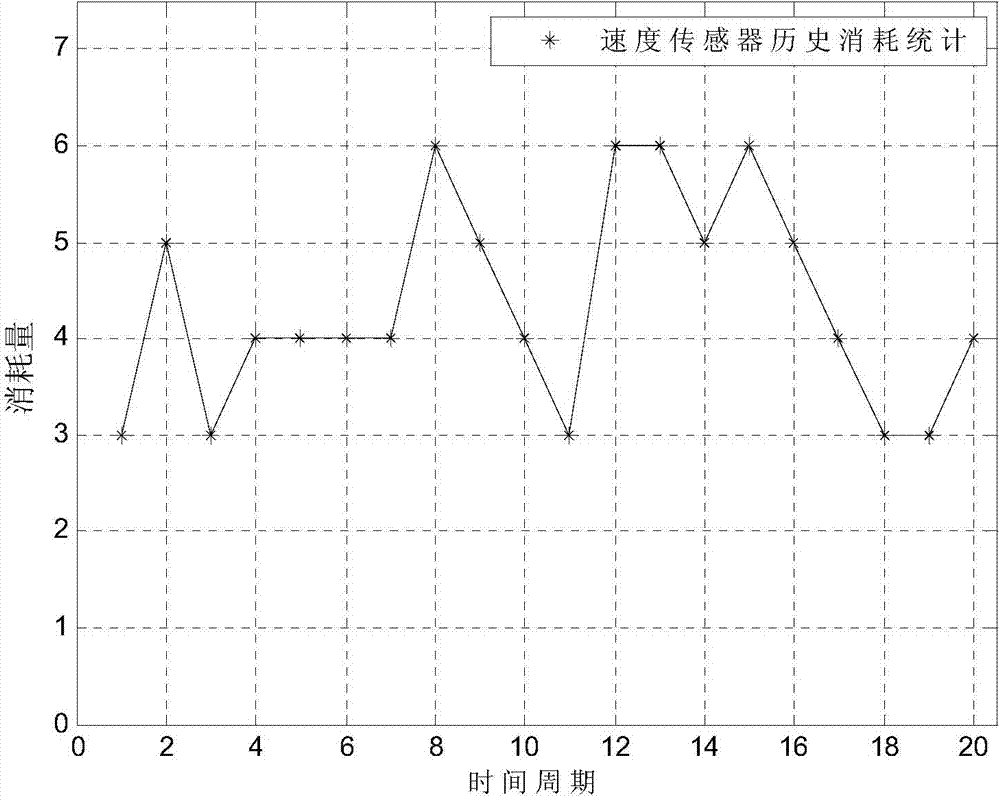

[0023] According to the input formula Calculate the total cost W in the replenishment cycle, where T is the replenishment cycle of spare parts, t is the replenishment cycle between two orders, Ri is the average consumption rate of spare parts, P is the price of spare parts per unit, h is the storage cost of spare parts per unit time, H is other storage costs in the replenishment cycle, E is the storage safety stock, S is the cost of a single purchase, n is the number of purchases in a replenishment cycle, and Q is the batch size of each purchase.

[0024] Step 2) Calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com