Runoff long-bag low-pressure pulse bag type dust collector

A technology of bag filter and low-pressure pulse, which is applied in chemical instruments and methods, climate change adaptation, climate sustainability, etc. It can solve the problem of excessive scouring of filter bags, poor sealing of flue ducts, and susceptibility to interference from weather factors, etc. problem, to achieve uniform flow rate and avoid flue gas scouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

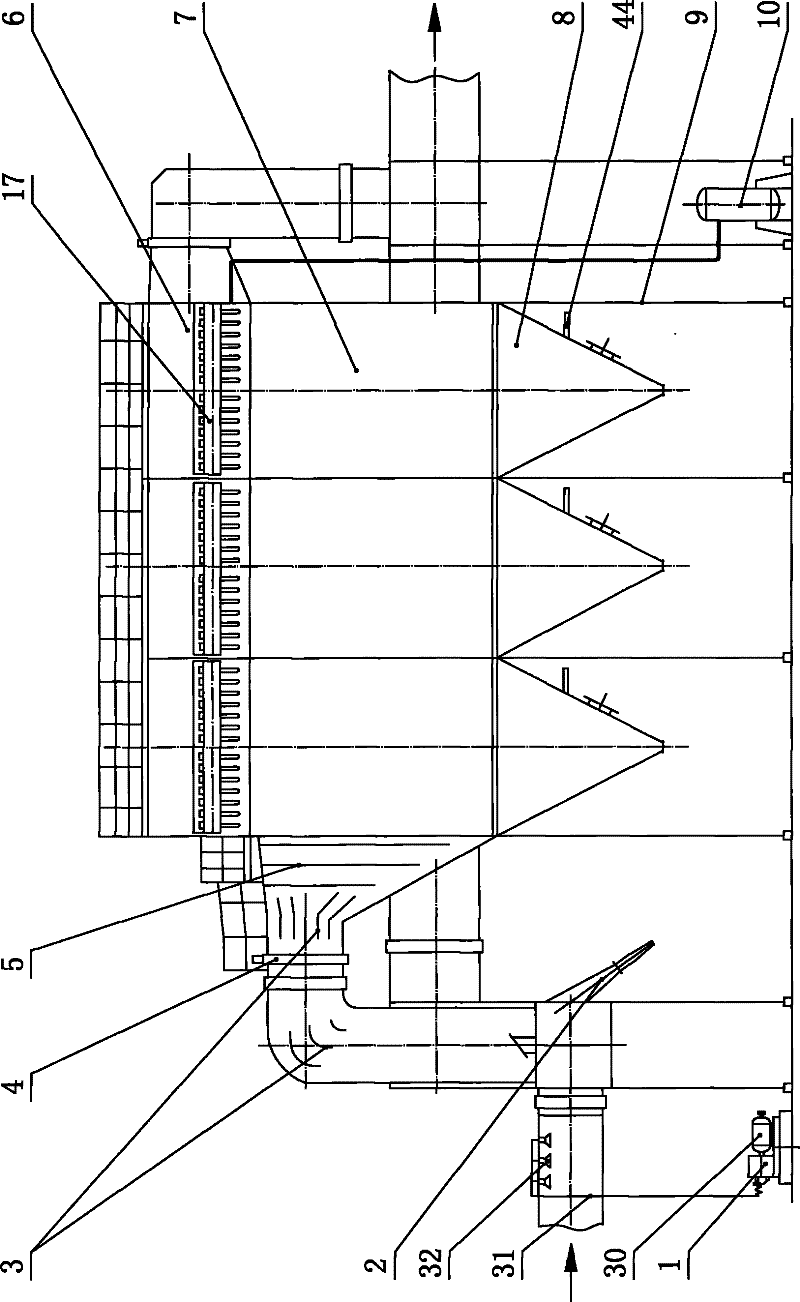

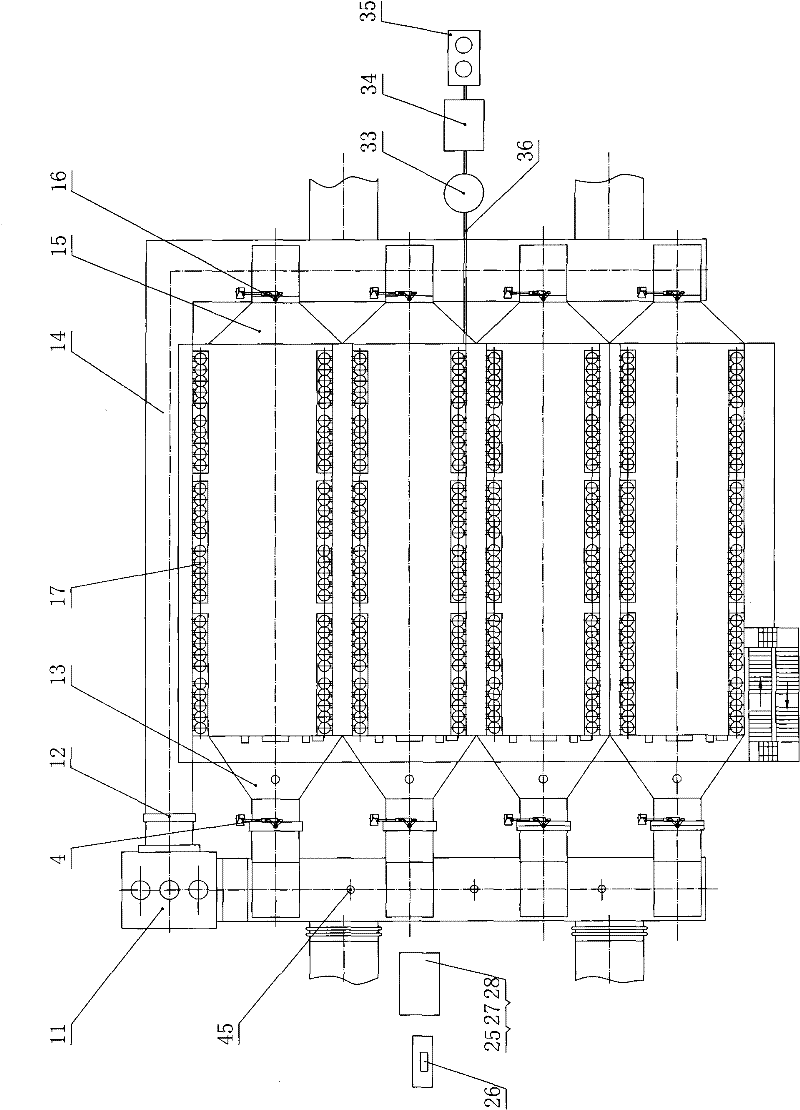

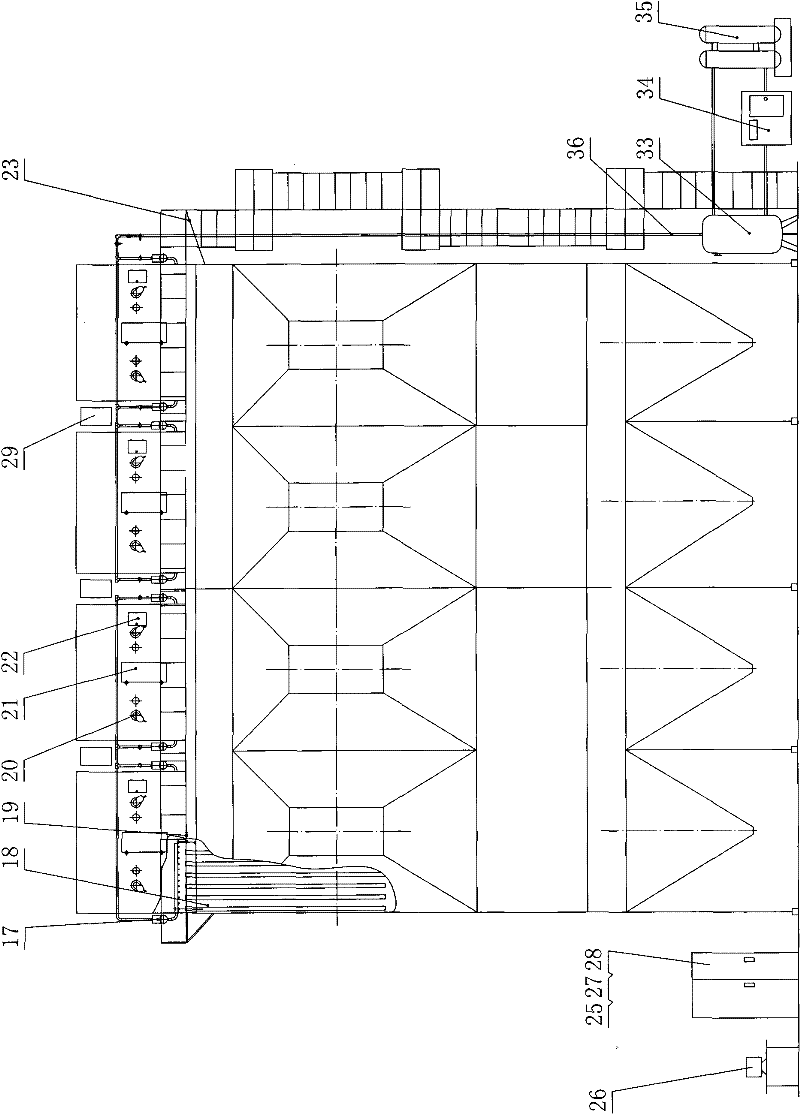

[0059] The radial-flow long-bag low-pressure pulse bag filter consists of: a group of single bag filter and its controller, the controller includes a PC cabinet 25, and the PC cabinet is respectively connected to an industrial control computer 26, Program logic controller 27, motor control center 28, field control box 29; The temperature sensor 44 that is respectively installed on the inlet flue of described single bag filter, is respectively installed in the collection of described single bag filter The material level sensor 45 on the ash hopper, and the differential pressure sensor 22 respectively installed on the clean air chamber housing of the single bag filter and the dust air chamber housing of the single bag filter , the single bag filter is a parallel structure.

Embodiment 2

[0061] The aforementioned radial-flow long-bag low-pressure pulse bag filter, the single bag filter includes a steel bracket 9, the dust and gas chamber 7 is installed on the steel bracket, and one end of the dust and gas chamber is connected to The air intake smoke box 13, the other end is connected to the air outlet smoke box 15, the dust chamber is connected to the clean air chamber 6 above, the ash collecting hopper 8 is connected to the bottom, and the dust chamber shell is connected to flower plate 19, the flower plate is connected to the filter bag device 18, the inlet smoke box is connected to the inlet flue 23 and the inlet stop valve 4 respectively, and the outlet smoke box is connected to the outlet flue 24 and the An outlet stop valve 16, the inlet flue and the outlet flue are respectively connected to the bypass flue 14, the clean air chamber is connected to the injection system 17, and the injection system is connected to the air supply system 10, The inlet flue ...

Embodiment 3

[0063] For the radial-flow long-bag low-pressure pulse bag filter described above, the injection system includes a pulse valve 37, the pulse valve is connected to the air bag 38, the air bag is connected to the blowing pipe 39, and the blowing pipe is connected to Nozzle 40. The blowing system adopts the uniform flow blowing technology, the nozzle diameter is φ50, and the length is 60mm. , φ22, φ23, φ24, φ26 and other different pore diameters, so that the intensity of the blowing airflow entering each filter bag is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com