Forecasting method for descending depth of material surface of blast furnace during furnace shutting down

A prediction method and a technology for reducing the material surface, which are applied in the field of blast furnace ironmaking, can solve problems that affect the safety of the shutdown of the blast furnace, increase the maintenance period and cost of the blast furnace, and easily form explosive gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

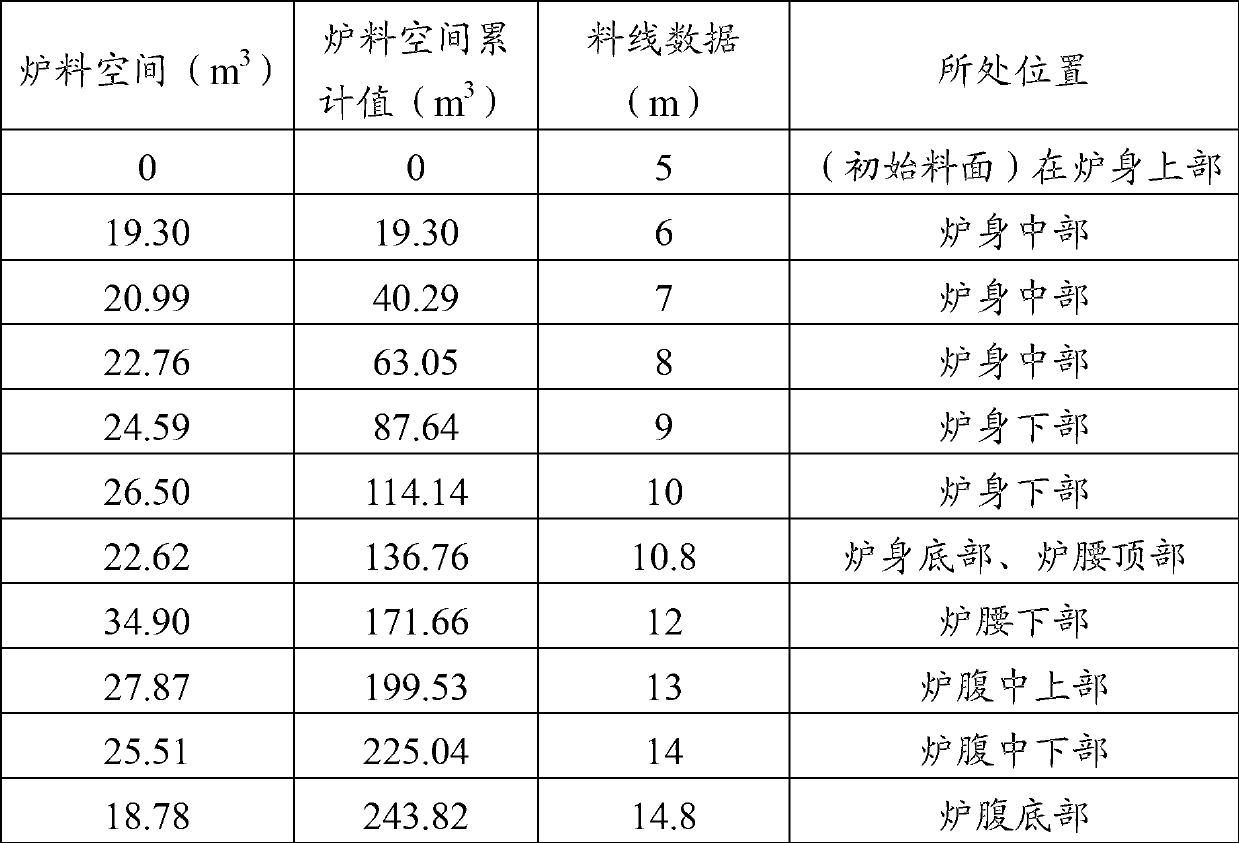

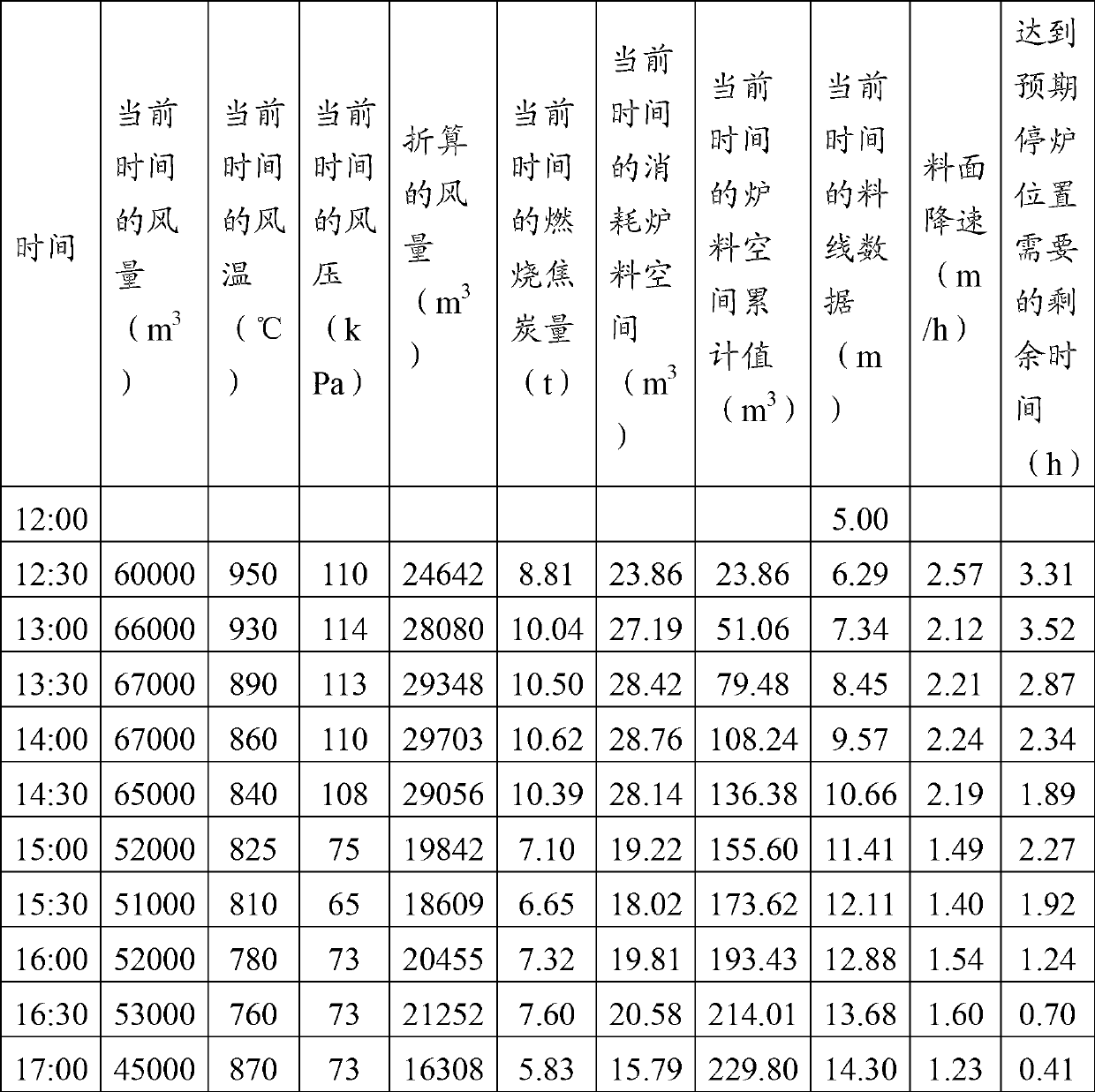

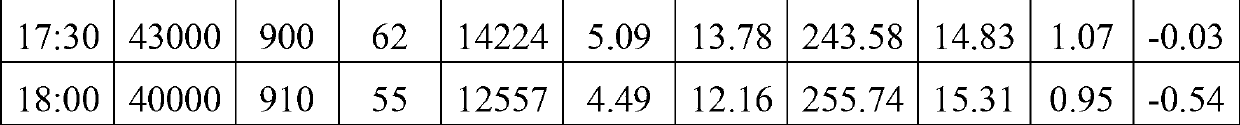

[0038] Set n material lines in the blast furnace and n material line data respectively corresponding to the n material lines, where n≥3 and is a positive integer. n can be a positive integer of ≥4, ≥5, ≥6, ≥7, ≥8, ≥9, ≥10, ≥11, ≥12 or ≥13.

[0039] The initial material level of the blast furnace shutdown is at the furnace throat or the upper part of the furnace body, which is the position where the blast furnace lowering level starts, that is, the first material line among the n material lines. The first material line corresponds to the first material line data among the n pieces of material line data. The first material line data is along the direction of blast furnace height, the distance between the first material line (that is, the position where the blast furnace descending surface starts) and the reference line (above the first material line).

[0040] The second material line to the nth material line are sequentially below the first material line. The i-th material li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com