Compact frame dedicated motor

A special motor, compact frame technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of the overall complex drive structure of the compact rack, troublesome installation and maintenance operations, and long drive response time, so as to improve the disassembly and maintenance operations. efficiency, improving production and installation efficiency, and accurate fault identification and judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

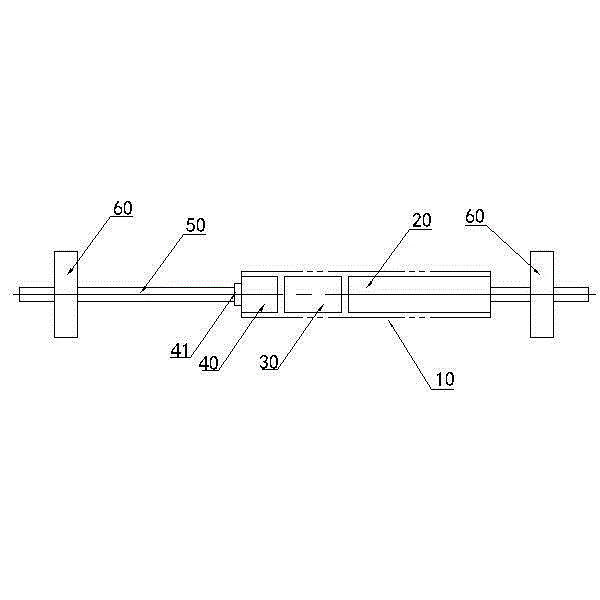

[0015] A special motor for a compact shelf, comprising a motor 20, a speed reducer 30 and a clutch 40, and the motor 20, the speed reducer 30 and the clutch 40 are jointly combined and driven to form an integral structure of a special motor 10 for a tubular compact shelf; the special motor 10 for a tubular compact shelf Among them, the motor 20 is directly connected to the clutch 40 through the planetary gear reduction mechanism of the reducer 30; the output of the clutch 40 is transmitted to the transmission shaft 50, and the drive wheels 60 at both ends of the transmission shaft 50 are realized to drive the compact rack body to move . The motor 20, the speed reducer 30 and the clutch 40 are sequentially arranged and installed in the special motor 10 for the tubular compact rack and connected together through transmission. The motor 20 adopts a deceleration motor to prevent that the driving speed is too fast to cause adverse situations such as moving damage to the compact she...

Embodiment 2

[0017] The motor 20 adopts a 24V DC motor, and the special motor 10 for the tubular compact rack is provided with an AC / DC adjustment control module that converts the 220V AC input into a 24V motor DC power supply. Of course, it is also possible to use a direct 24V external DC power input; the others are the same as in Embodiment 1.

Embodiment 3

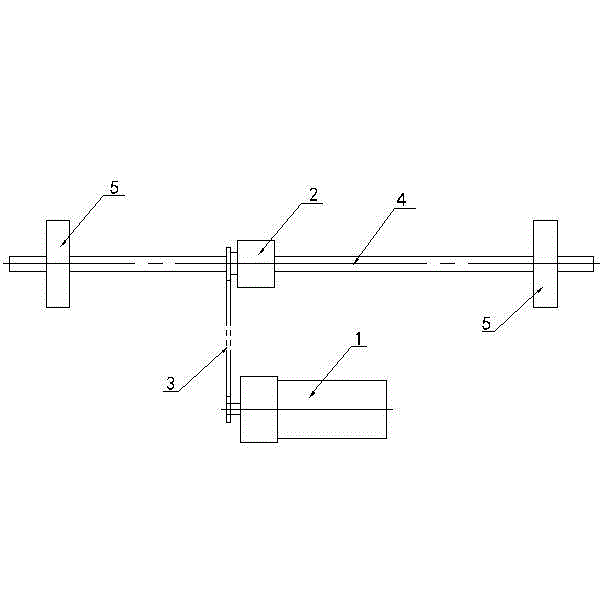

[0019] The special motor 10 for the tubular compact shelf is also provided with one group of spare special motor secondary groups made up of another motor 20 , speed reducer 30 and clutch 40 . When installing and using this moment, on the transmission shaft, a group of transmission gears matched with it can be added to effectively realize the effect of the spare special-purpose motor subgroup driving the transmission compact shelf; other are the same as embodiment 1.

[0020] During use, the output end gear of the special motor 10 for the tubular compact rack of the present invention is on the drive shaft 50, when the compact rack needs to be driven, the output end gear of the special motor 10 for the tubular compact rack is engaged with the drive gear on the drive shaft 50, Realize reliable and efficient driving of the drive wheels of compact racks. When the compact rack is stopped to move, the output gear of the tubular compact rack special motor 10 is separated from the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com