Fully sealed compact dustproof linear motor moving platform

A technology of linear motors and motion platforms, which is applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of difficulty in frequent disassembly and maintenance, and adsorption of iron chips, etc., to reduce sliding friction, increase effective force, reduce The effect of exercise resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

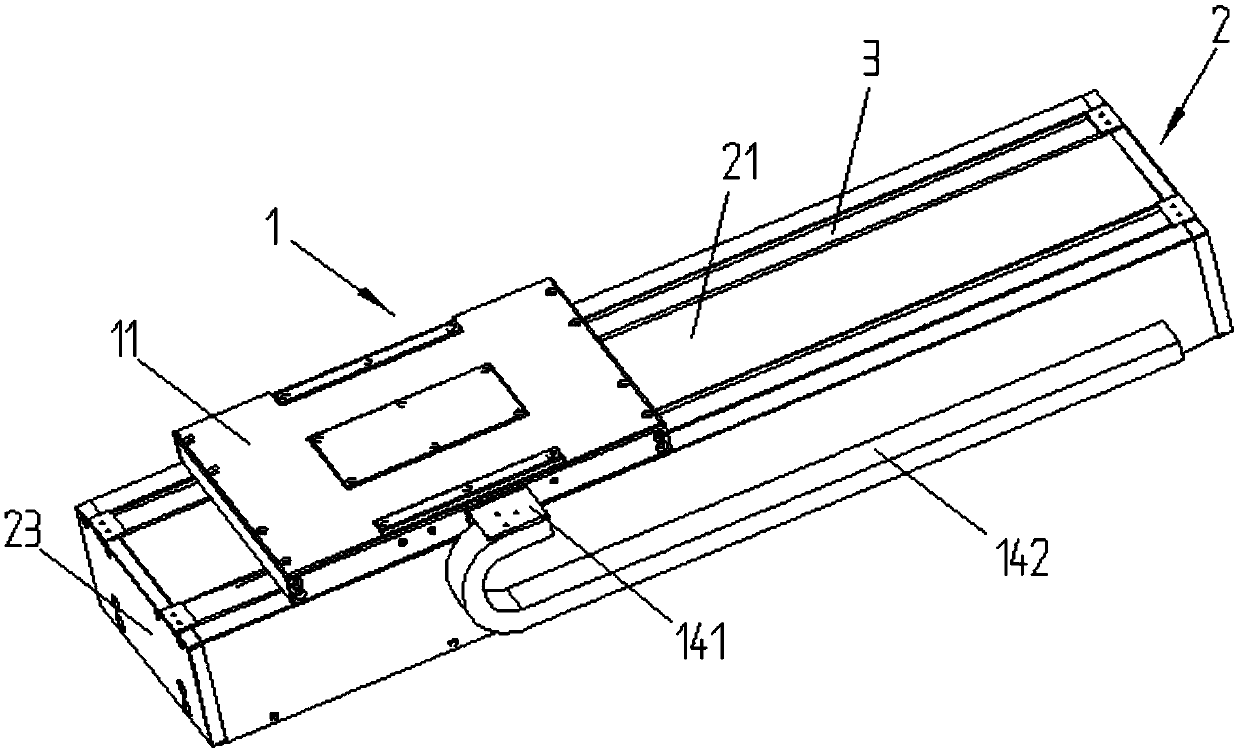

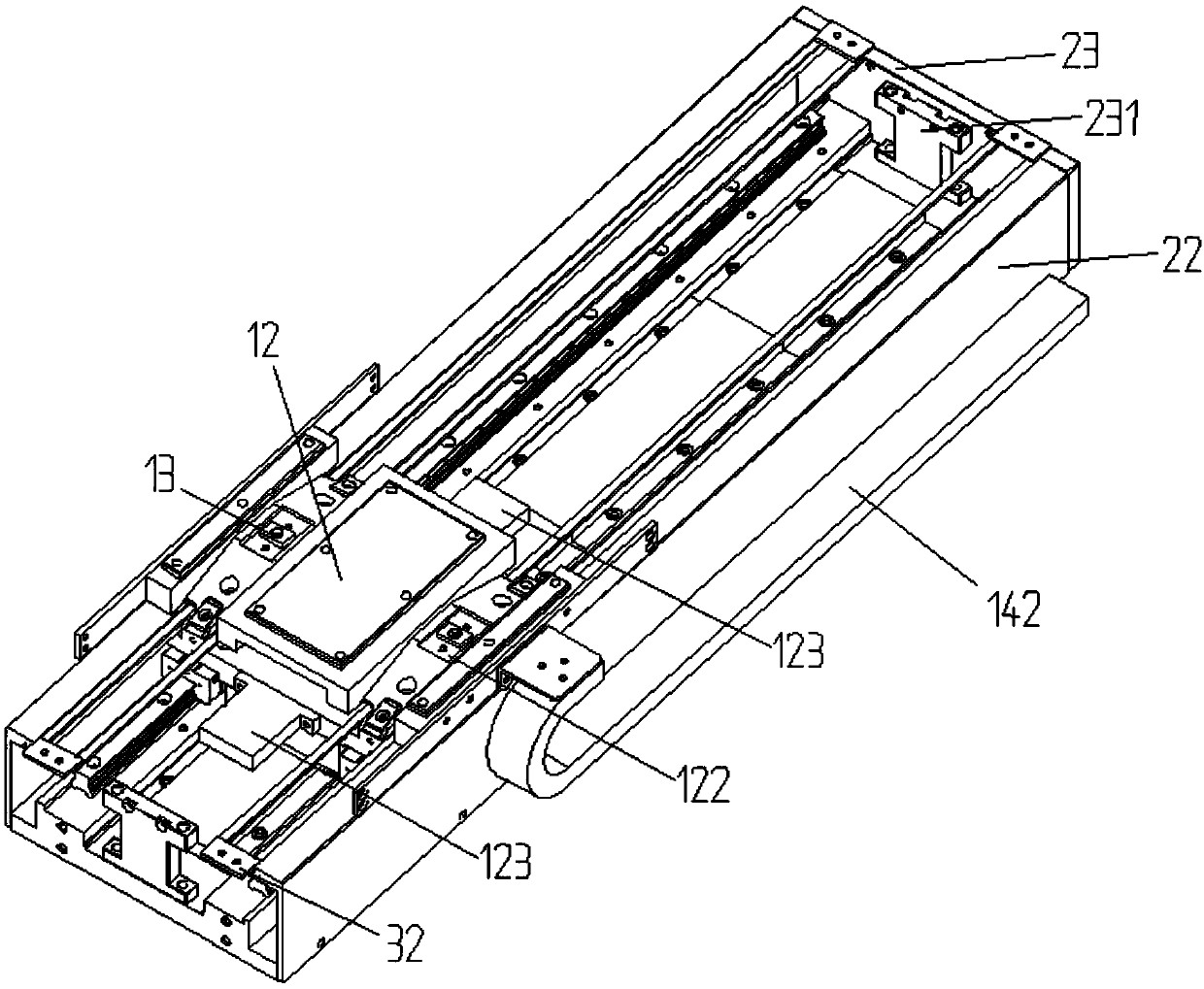

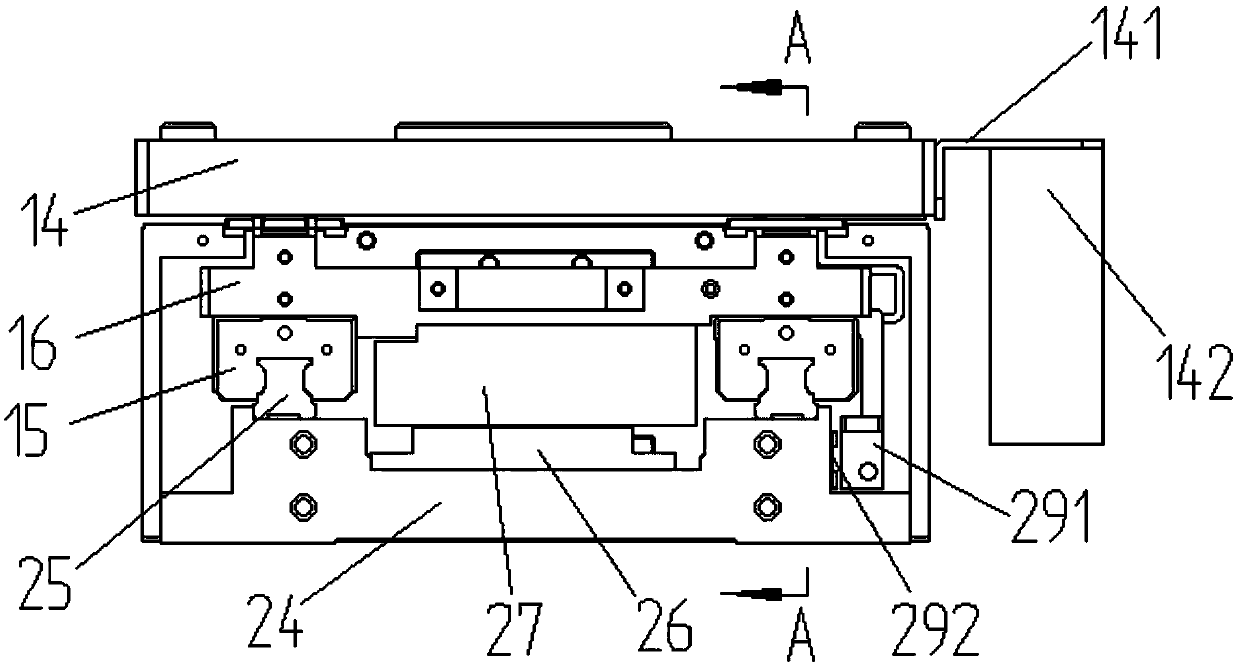

[0025] as attached Figure 1-5 As shown, a fully-sealed compact dust-proof linear motor motion platform includes a sliding mechanism 1, a closed base module 2 and a magnetic conductive steel belt 3; the magnetic conductive steel belt 3 is arranged on the closed base module 2 On the surface; U-shaped holes 31 are provided at both ends of the magnetic conductive steel belt 3, and are fixed with pressing blocks 32; the magnetic conductive steel belt 3 passes through the sliding mechanism 1, and the sliding mechanism 1 follows the magnetic conductive steel belt 3. sliding; the closed base module 2 includes an upper cover plate 21 , an L-shaped side cover plate 22 , an end plate 23 , a base 24 , a guide rail 25 and a stator 26 ; the magnetic conductive steel strip 3 is arranged on the upper cover plate 21 two sides; the L-shaped side cover plate 22 is arranged on the side of the magnetically conductive steel belt 3; the upper cover plate 21 and the L-shaped side cover plate 22 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com