Anti-blocking power mechanism of spherical compressor

A technology of spherical compressors and power mechanisms, which is applied in the direction of machines/engines, mechanical equipment, and swing piston pumps, can solve the problem that spherical compressors cannot adapt to microstructures, the advantages of spherical compressor surface seals are reduced, concave slideways and Guide pin wear and other problems, to achieve good coolant lubrication effect, stable and reliable operation of the mechanism, and prevent the mechanism from being stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

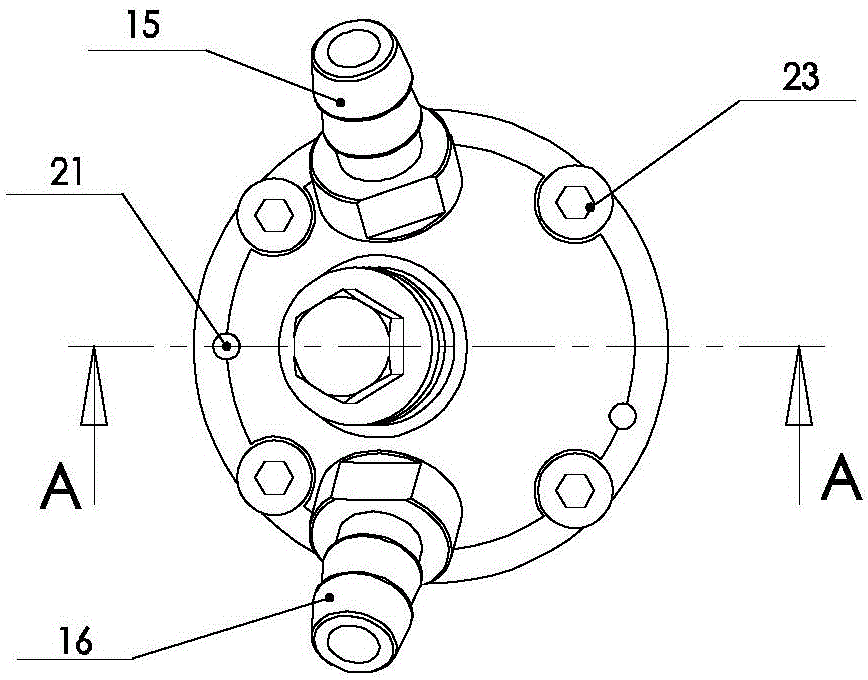

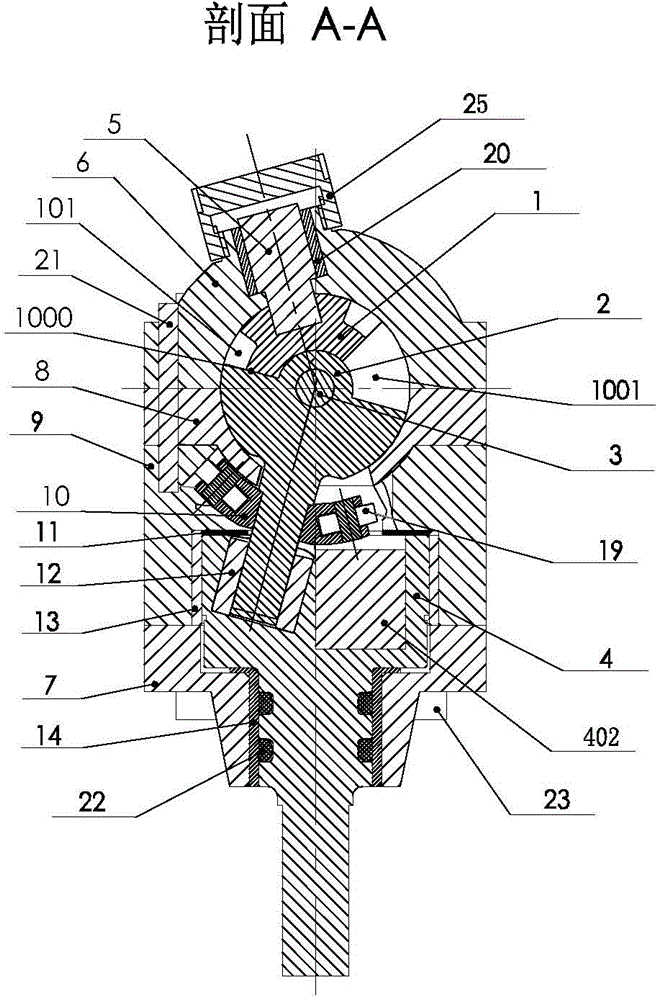

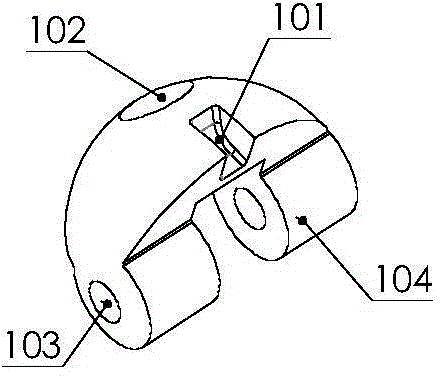

[0042] Such as figure 1 , figure 2 As shown, the spherical compressor includes a piston 1, a turntable 2, a center pin 3, a main shaft 4, a cylinder head 6, a cylinder body 8, a cylinder body seat 9 and a main shaft support 7, a cylinder head 6, a cylinder body 8, a cylinder body seat 9, The main shaft support 7 is connected successively by connecting screws 23 to form a casing of a spherical compressor; Figure 5 , Figure 6 and Figure 7 As shown, the cylinder head 6 and the cylinder body 8 have a hemispherical inner surface, and are connected by connecting screws 23 to form a spherical inner cavity of a spherical compressor. The cylinder block seat 9 is connected to the lower part of the cylinder body 8 by connecting screws 23. In order to ensure that the spherical surfaces fit together The positioning is accurate, and positioning pins 21 are arranged at the connecting parts of the cylinder head 6, the cylinder body 8 and the cylinder body seat 9.

[0043] in such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com