Turntable rotation synchronization mechanism used for spherical compressor

A spherical compressor and rotational synchronization technology, applied in the components of pumping devices for elastic fluids, machines/engines, and rotary piston/oscillating piston pump components, etc. Problems such as the power of piston rotation to achieve the effect of not easy to stick and solve the problem of dead center

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

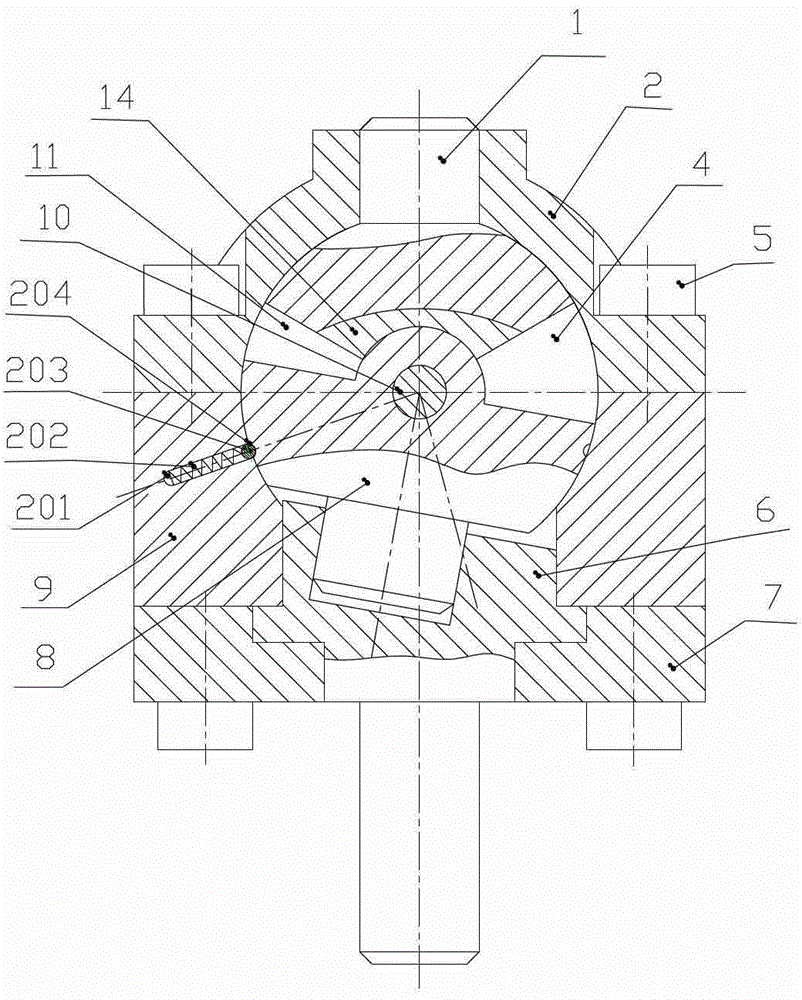

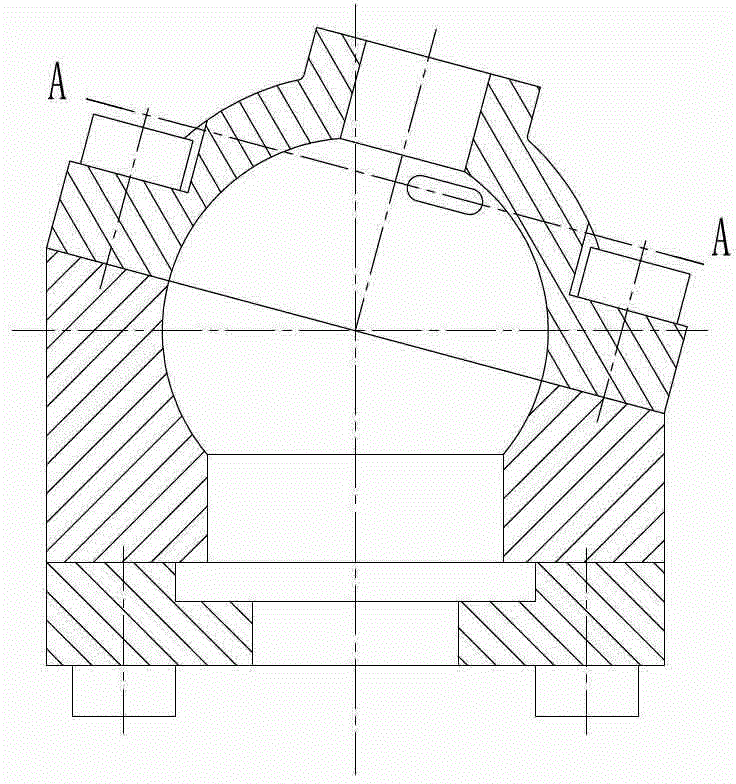

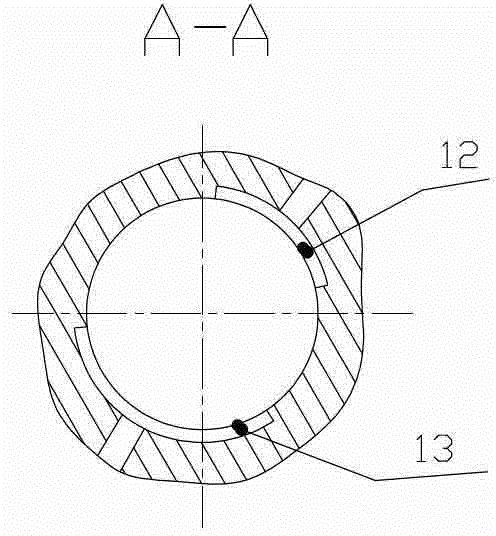

[0026] Such as figure 1 Shown is the structural diagram of the compressor of the embodiment of the present invention. The spherical compressor includes a cylinder 9, a cylinder head 2, a piston 1, an insert 14, a turntable 8, a main shaft 6, a main shaft support 7 and a center pin 10, and the cylinder 9 and The cylinder head 2 is connected by connecting screws 5 to form a spherical inner cavity; Figure 7 , Figure 8 As shown, the piston 1 has a spherical top surface, a piston shaft extending from the center of the spherical top surface, two side surfaces at a certain angle, an air passage 3 and a piston pin seat formed at the lower part of the two sides of the piston 1, the piston pin seat is half Cylindrical structure, with a groove in the middle of the semi-cylindrical, and a through pin hole in the axial direction; the cylinder head 2 is provided with a shaft hole matching the piston shaft, and the piston 1 can rotate freely in the shaft hole around the piston shaft. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com