Voice coil motor and assembly process thereof

A technology of voice coil motor and assembly process, which is applied in the direction of electromechanical devices, electric components, and manufacturing motor generators, etc. It can solve problems such as unpopularization of application fields, large spring torque, deformation of upper and lower shrapnel, etc., to improve life and activity. The effect of increasing space and enhancing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

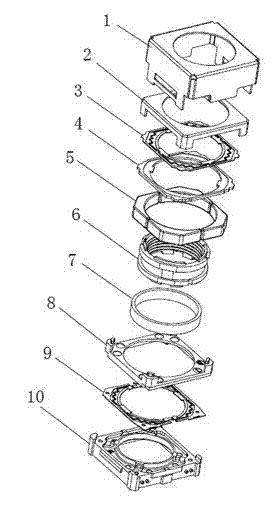

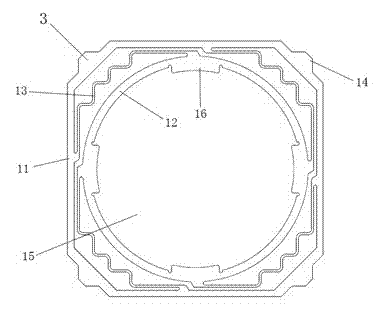

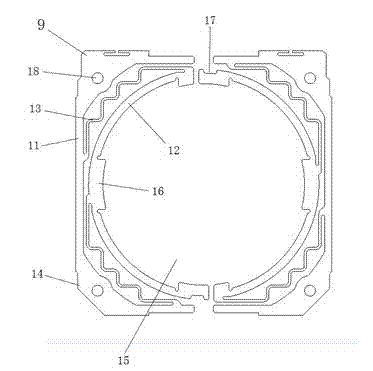

[0018] Such as Figure 1-3 As shown, a voice coil motor flat shrapnel includes upper and lower flat shrapnels (3, 8) with the same overall shape and structure, the upper flat shrapnel (3) has an integrated structure, and the lower flat shrapnel (8) is Split structure; the upper and lower plate springs (3, 8) are used as a set, fixed by dispensing glue or spot welding on the protrusions and the holes on the protrusions; the upper and lower plate springs (3, 8) include inner Frame (12), outer frame (11) and elastic part (13); said elastic part (13) is 4 or 6 equisine wave-shaped elastic chords, evenly distributed in the inner frame (12) of the flat shrapnel Between and the outer frame (11), one end of the elastic part (13) is connected to the inner edge of the outer frame (11), and the other end is connected to the outer edge of the inner frame (12). Make the force uniform and improve the stability.

[0019] The inner frame (12) of the upper and lower plate springs (3, 8) is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com