High-efficiency resonator manufacturing device

A technology for manufacturing devices and resonators, which is applied in the field of high-efficiency resonator manufacturing devices, can solve the problems of high production costs and heavy labor, and achieve the effect of reducing labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

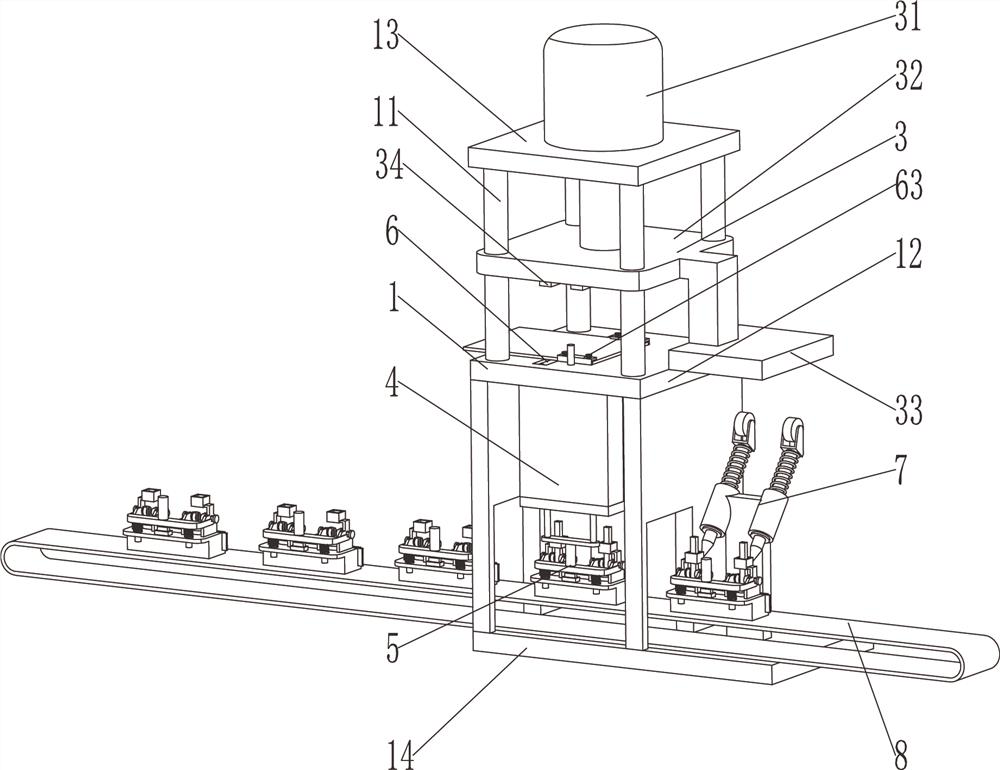

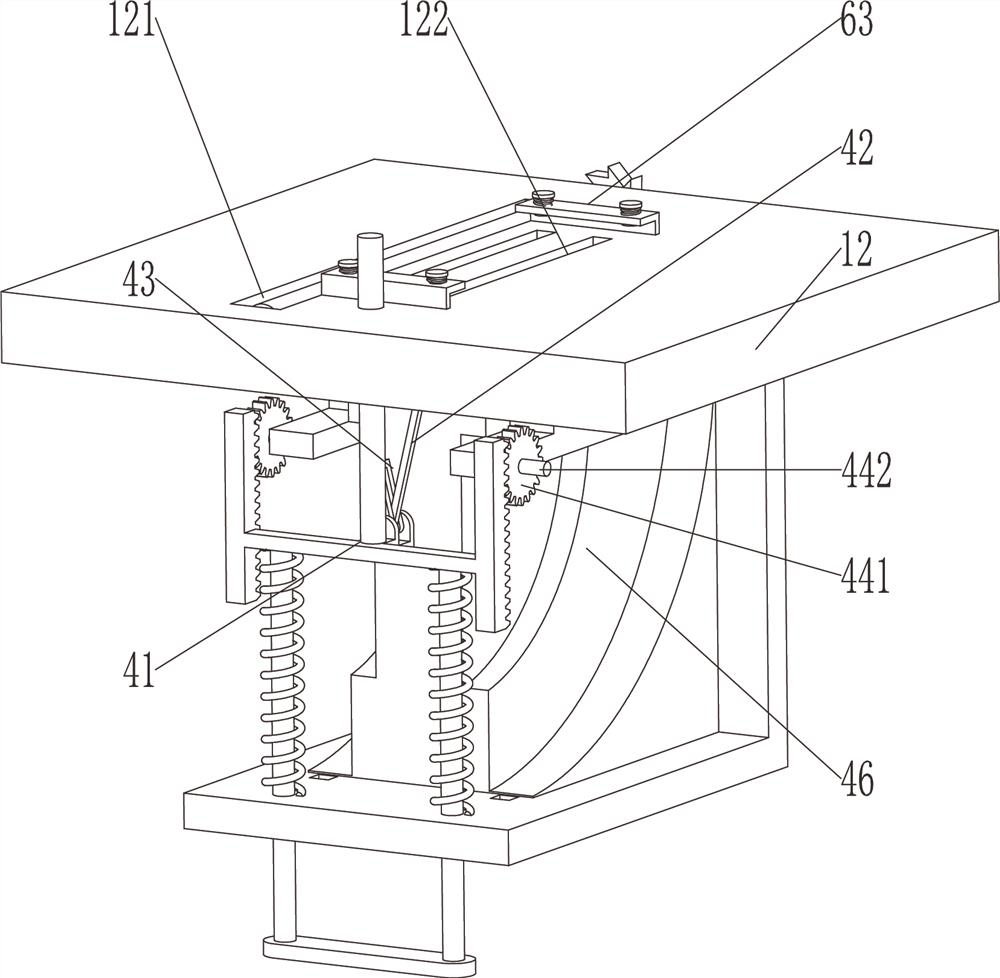

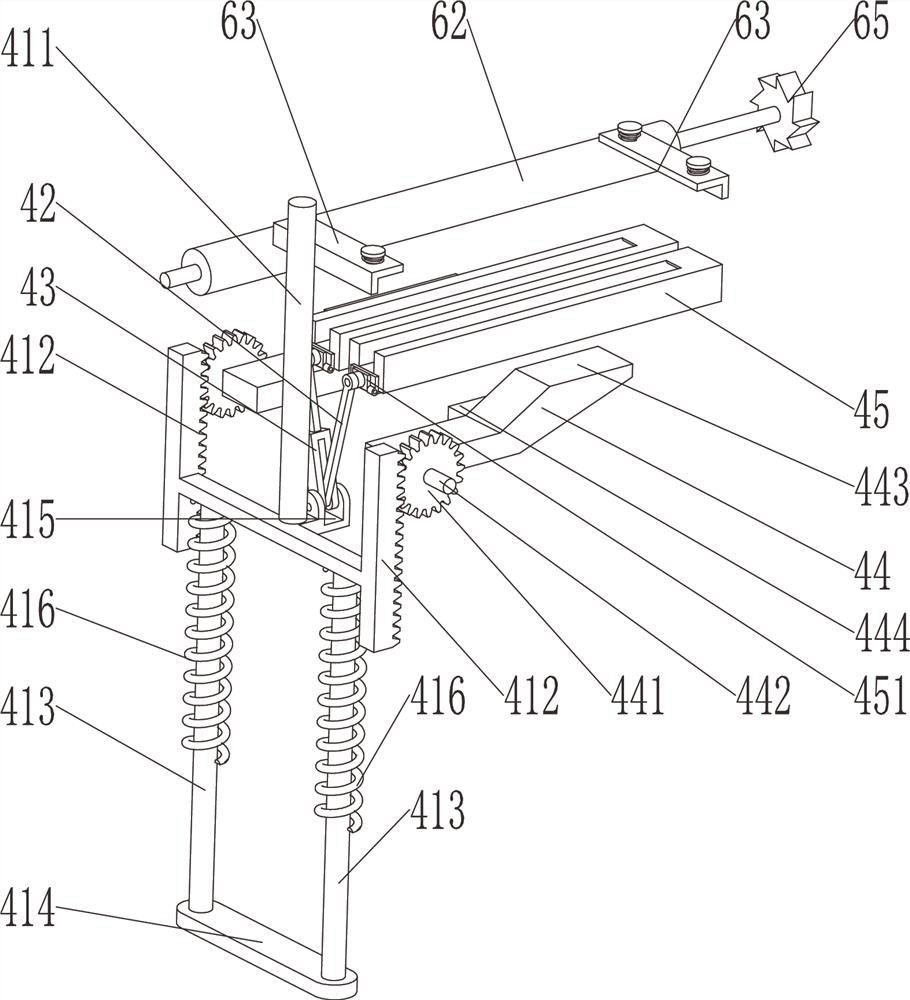

[0025] see Figure 1-Figure 5 , a high-efficiency resonator manufacturing device, including a base 1, a stamping part 3 and a distribution mechanism 4, the base 1 includes a cavity plate 12, an upper top plate 13 and a lower bottom surface 14, the cavity plate 12 and the upper top plate 13 Several guide rods 11 are provided, and the stamping part 3 includes a stamping power part 31, a stamping sliding plate 32, a shifting tooth combination 35 and a linkage plate 33, and the stamping sliding plate 32 is slidably arranged on the guide rod 11, and the stamping power The component 31 is arranged on the top of the base 1, and its telescoping rod is connected with the stamping sliding plate 32, wherein it provides the power to slide up and down for the stamping sliding plate 32, the bottom of the stamping sliding plate 32 is provided with a punch 34, the cavity plate 12 A punching hole 122 is arranged on the top, and such a resonator is a double-pin design, so there are two punches ...

Embodiment 2

[0032] see Figure 1-Figure 9, a high-efficiency resonator manufacturing device, including a base 1, a stamping part 3, a welding mechanism 7, a feeding mechanism 6, a distribution mechanism 4, a conveying mechanism 5 and a clamping device 5, the base 1 includes a cavity plate 12, an upper The top plate 13 and the lower bottom surface 14, the cavity plate 12 and the upper top plate 13 are provided with several guide rods 11, and the stamping part 3 includes a stamping power part 31, a stamping sliding plate 32, a shifting tooth combination 35 and a linkage plate 33. The stamping sliding plate 32 is slidingly arranged on the guide rod 11, the stamping power part 31 is arranged on the top of the base 1, and its telescopic rod is connected with the stamping sliding plate 32, wherein it provides the power for the stamping sliding plate 32 to slide up and down, A punch 34 is provided at the bottom of the stamping sliding plate 32, and a punching hole 122 is arranged on the cavity p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com