Drum-type hydraulic turner

A turning and throwing machine and drum-type technology, which is applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problems of high price, complexity, and low efficiency of mechanical transmission machinery, so as to improve reliability and reduce The effect of the intermediate transmission link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

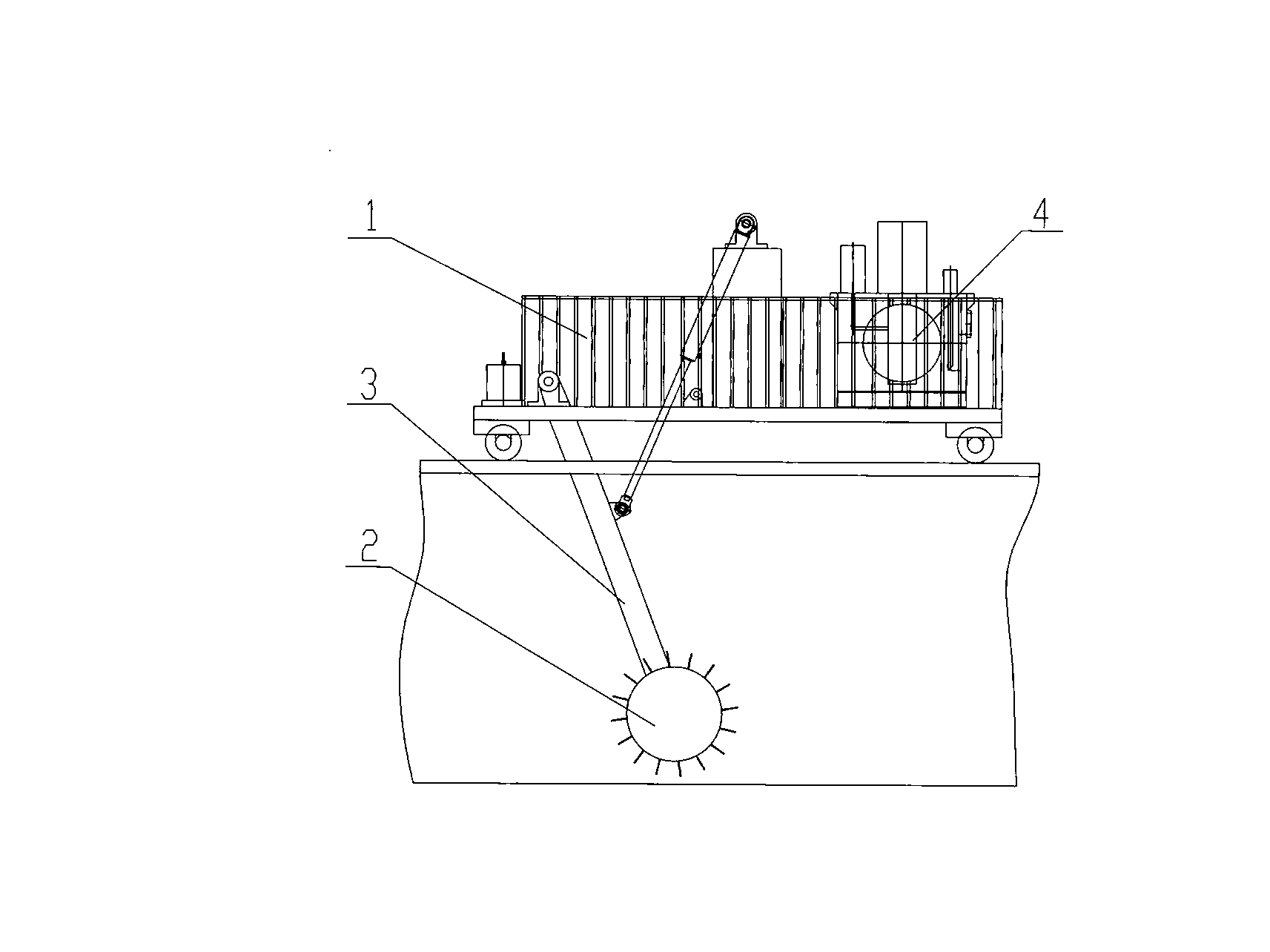

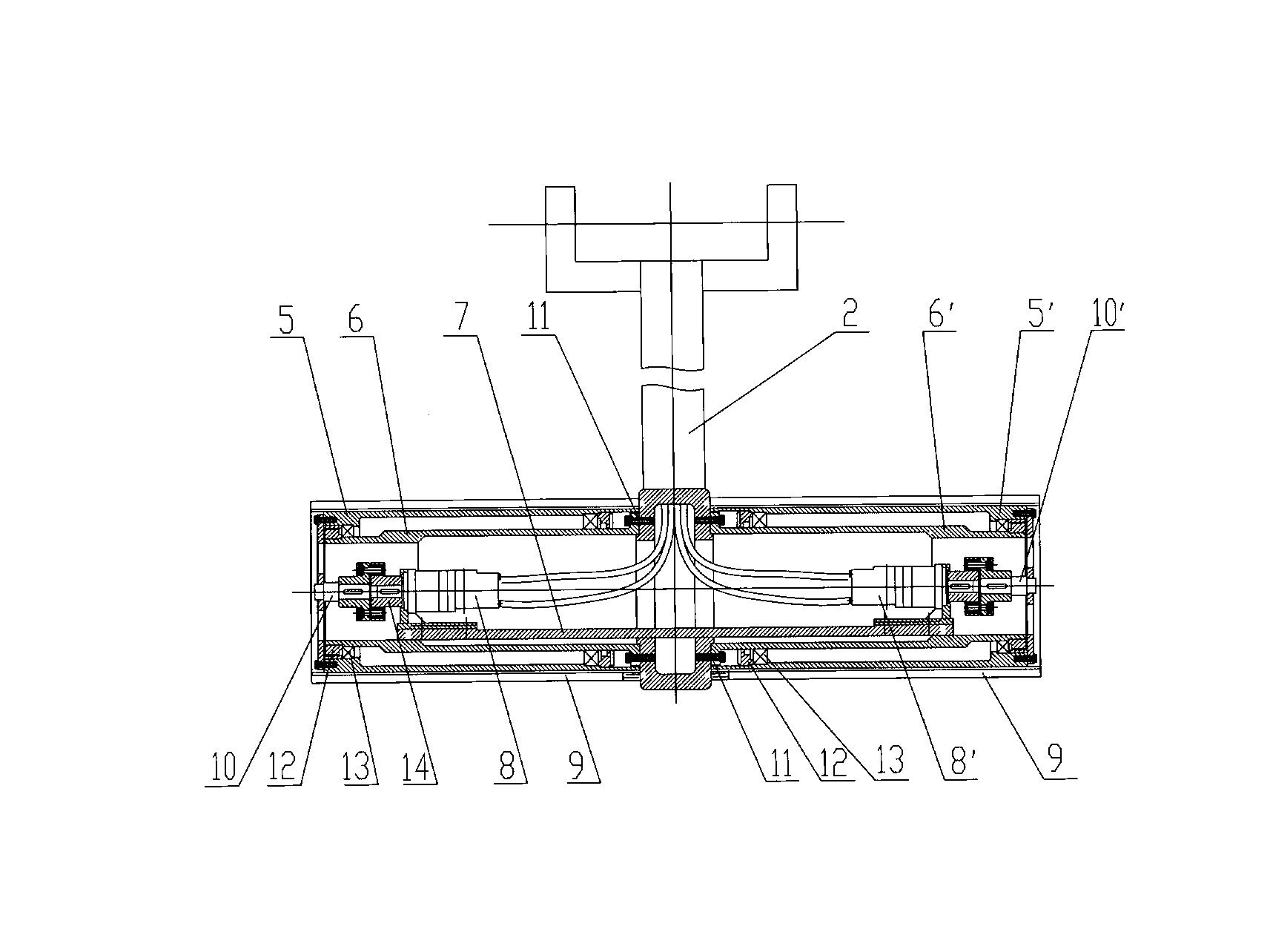

[0015] Examples such as figure 1 , figure 2 As shown, a drum type hydraulic turning and throwing machine includes a frame 1, a boom 3 connected to the frame 1, and a hydraulic device 4 installed on the frame 1, connecting the lower part of the boom 3 in the middle The roller device 2. The roller device 2 comprises a left roller 5 and a right roller 5', a left hydraulic motor 8 and a right hydraulic motor 8'; a plane blade 9 is arranged on the outside of the left roller 5 and the right roller 5', and the plane blade 9 is arranged along the left roller 5 and the right roller. 5' are axially symmetrically distributed and rectangular; the left sleeve 6 and the right sleeve 6' are respectively arranged inside the left drum 5 and the right drum 5', and the installation platform 7 is welded inside the left sleeve 6 and the right sleeve 6' , the left hydraulic motor 8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com