Double-edge arc-shaped permanent magnet synchronous motor used for large turntable

A permanent magnet synchronous motor, a large-scale technology, applied to synchronous motors with stationary armatures and rotating magnets, the shape/style/structure of winding conductors, and stationary components of magnetic circuits, etc. It can improve the transmission accuracy and transmission efficiency, reduce the difficulty of processing and transportation, and reduce the local deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

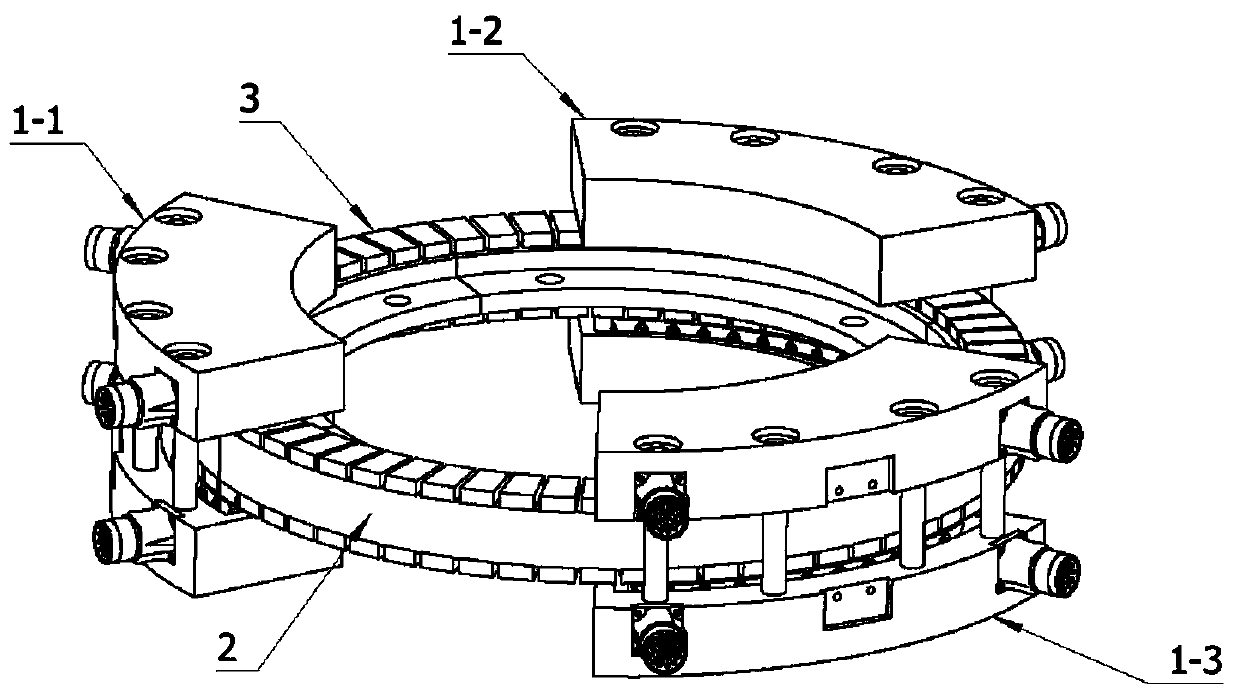

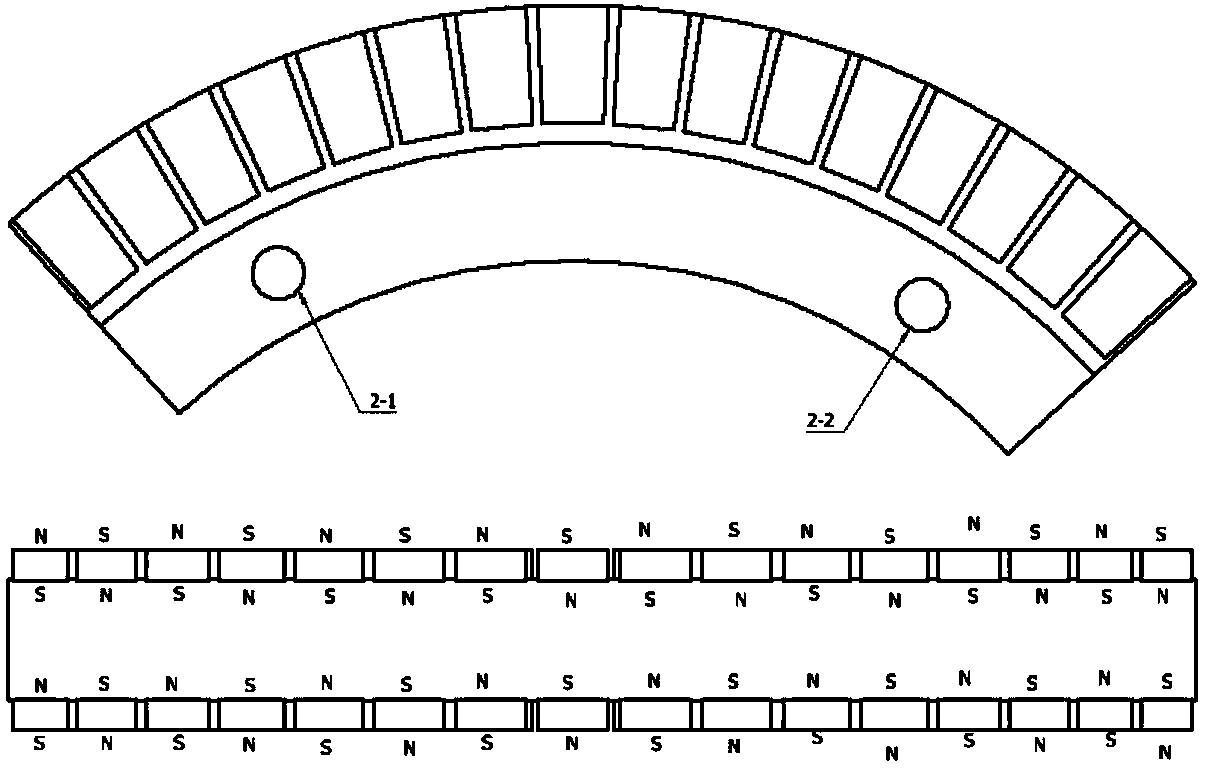

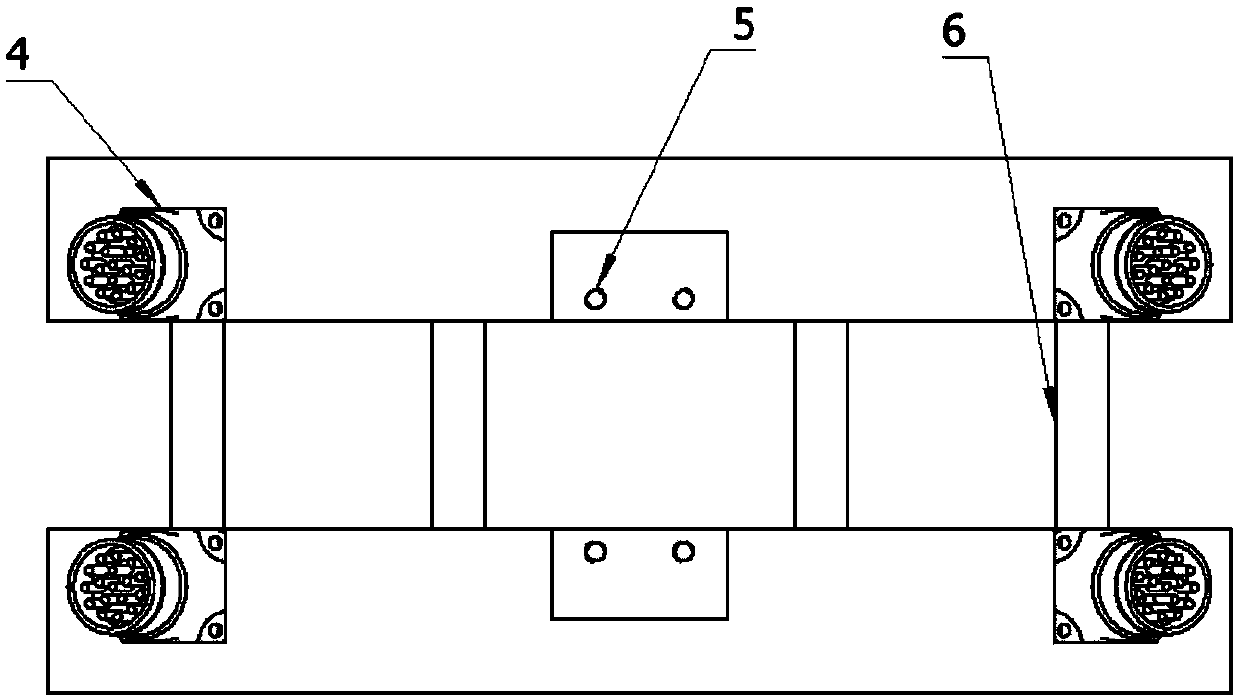

[0017] Such as figure 1 An example overall structure of a double-sided arc-shaped permanent magnet synchronous motor used in a large turntable according to the present invention is shown. The motor is mainly composed of three stator groups 1-1, 1-2, 1-3, and a rotor. Each stator group has exactly the same structural form, consisting of two upper and lower stator parts, and the upper and lower stator groups are connected and positioned by the connecting piece 6 . Such as image 3 , 4 , Each stator group shown in 5 is composed of two identical stator pieces, connecting piece 6, iron core positioning piece 11, coil winding 12, iron core unit 13, and stator shell. refer to Figure 4 , Figure 5 , Figure 7 As shown, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Remanence | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com