Multistage parallel heavy-load electric cylinder

An electric cylinder, a first-class technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of large-scale vertical launch, large impact of level change, etc., to improve transmission efficiency and transmission speed, large load capacity, increase Effect of Bending and Torsional Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0022] The invention provides a multi-stage parallel heavy-duty electric cylinder.

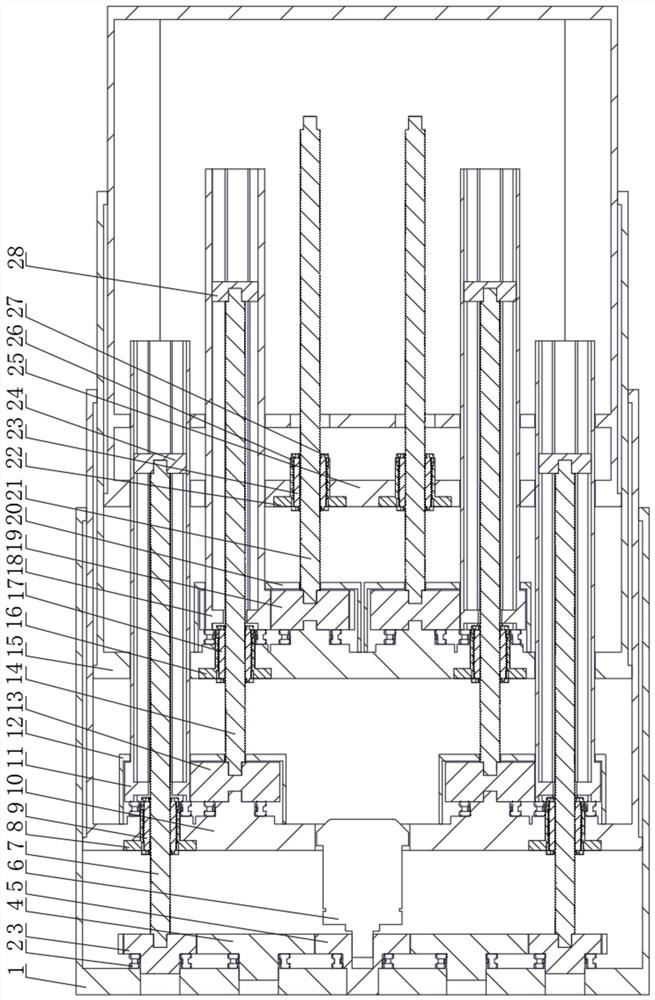

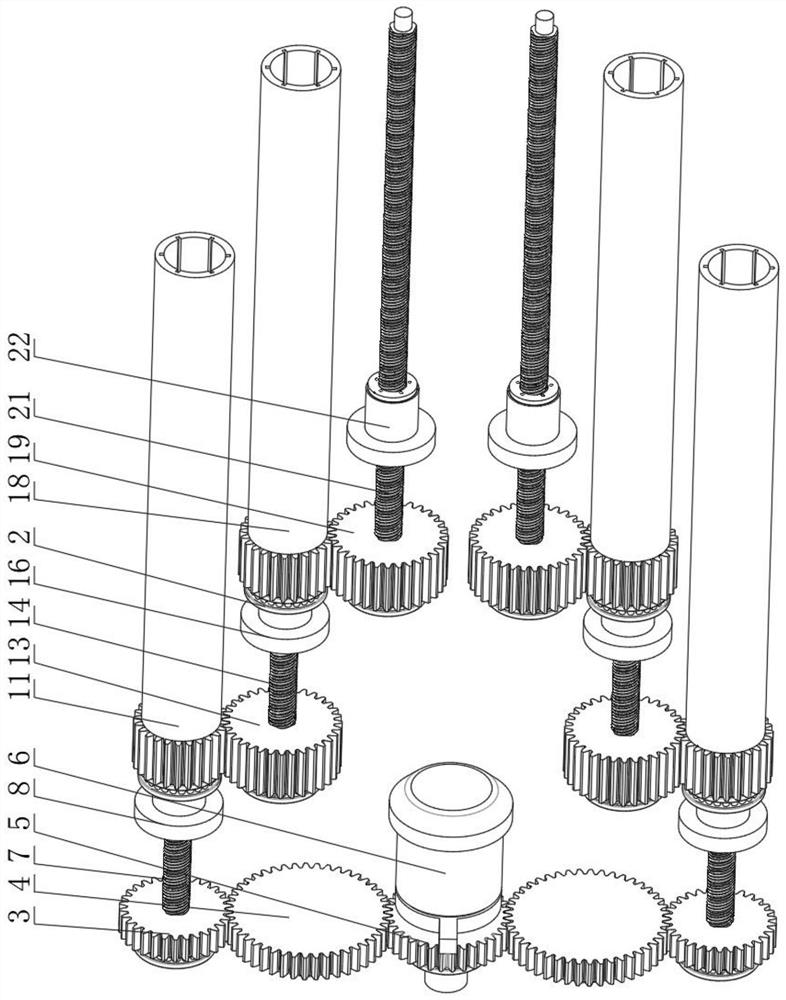

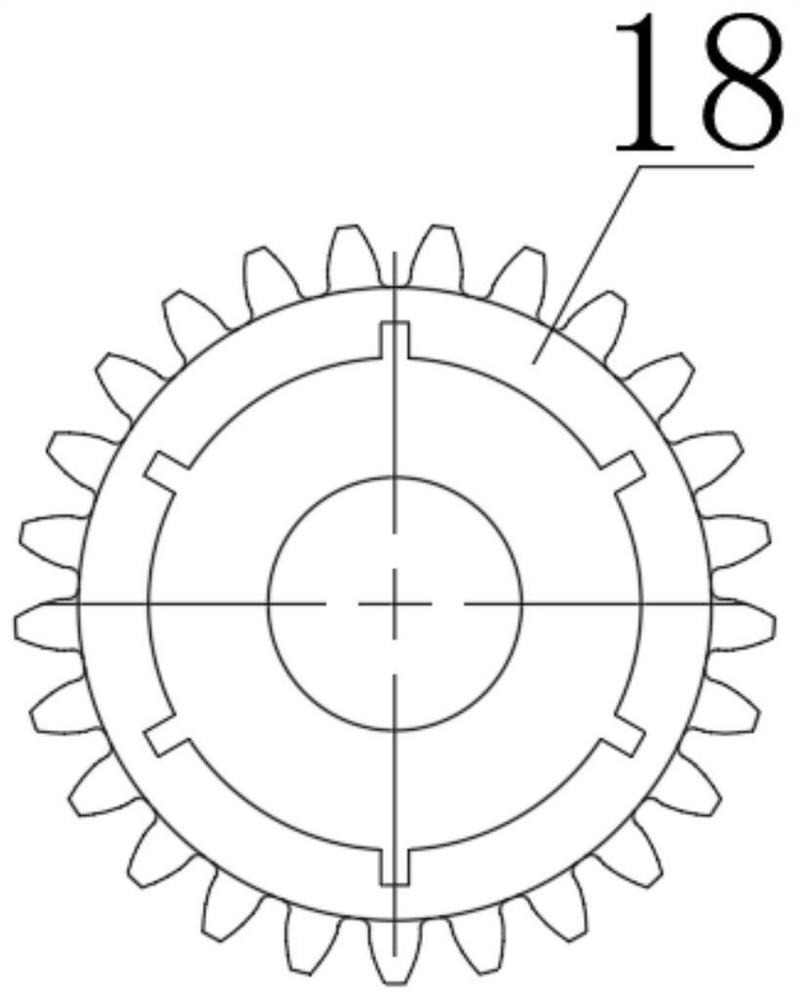

[0023] Such as figure 1 , figure 2 and image 3As shown, the electric cylinder includes base cylinder 1, thrust cylindrical roller bearing 2, primary input gear 3, reduction gear 4, motor output gear 5, servo motor 6, primary planetary roller screw shaft 7, primary Nut 8, roller A9, primary cylinder 10, transmission cylinder A11, protective cover A12, secondary input gear 13, secondary planetary roller screw shaft 14, secondary cylinder 15, secondary nut 16, roller B17, drive cylinder B18, tertiary input gear 19, protective cover B20, tertiary planetary roller screw shaft 21, tertiary nut 22, roller C23, spline A24, tertiary cylinder 25, inner ring gear 26, Roller c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com