Plunger pump driven by linear motor

A linear motor and driven technology, applied in the field of plunger pumps, can solve problems such as large friction and wear, unstable discharge pressure, and low system efficiency, and achieve the effects of reduced friction and wear, convenient maintenance, and high system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

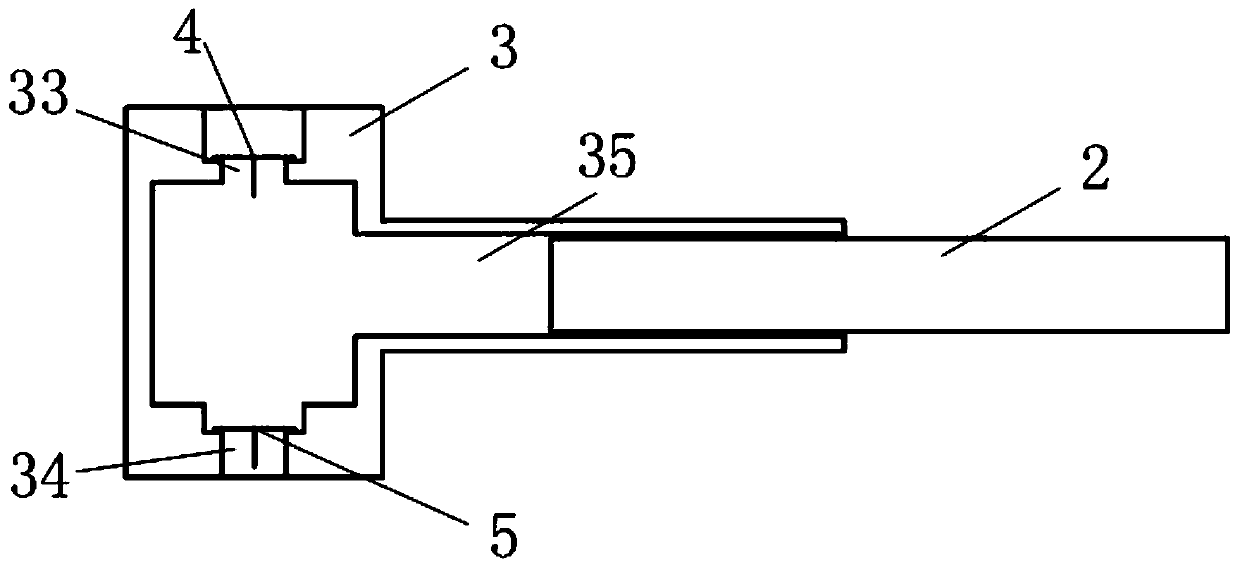

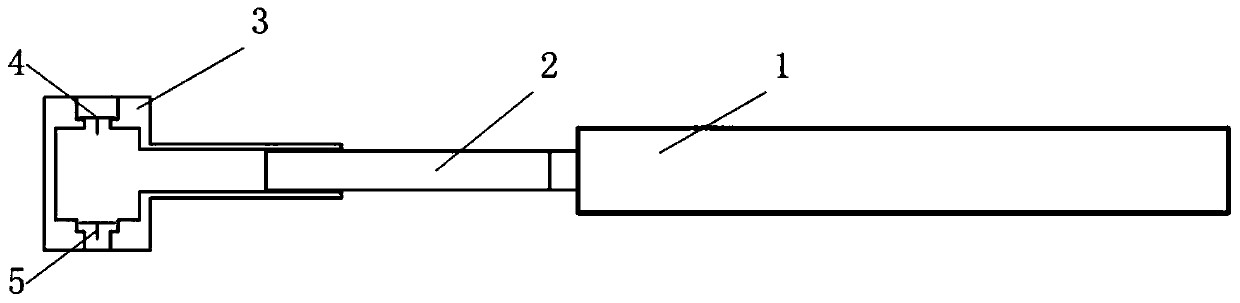

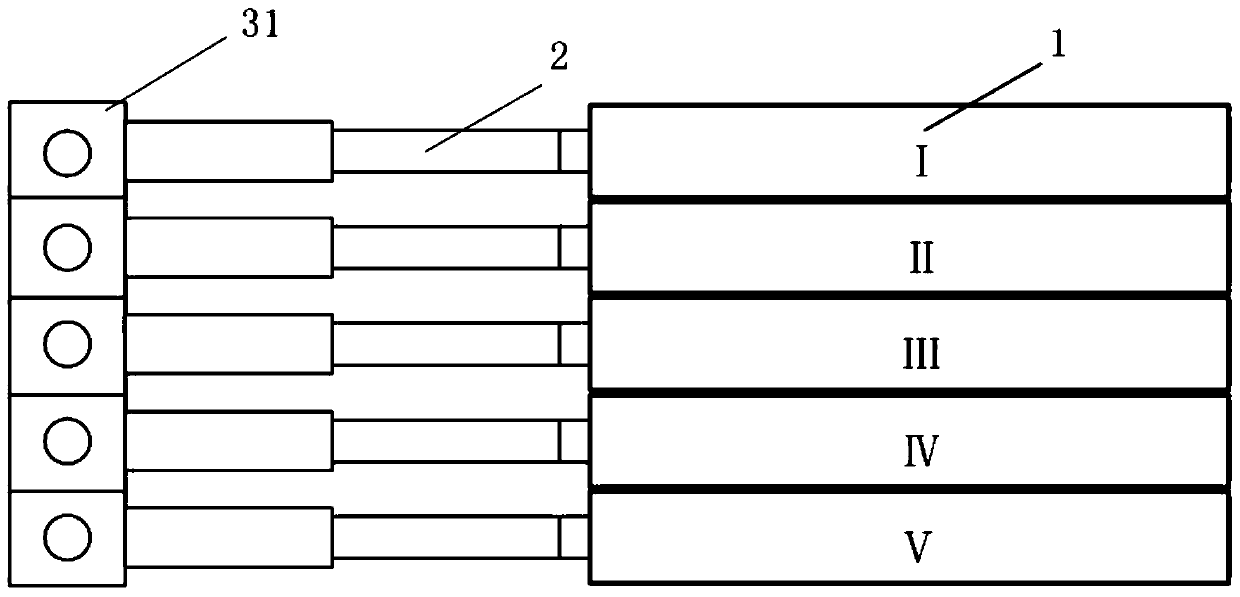

[0023] Such as Figures 1 to 10 As shown, a linear motor-driven plunger pump includes a linear motor and a liquid end assembly, the linear motor is a single-acting linear motor 1 or a double-acting linear motor 9, and the linear motor and the liquid end assembly The fluid end assembly includes a plunger 2, a valve box 3, an upper valve body 4 and a lower valve body 5, and the valve box 3 is a single-cylinder combined valve box 31 or a multi-cylinder valve box 32. The single-cylinder combined valve box 31 includes a two-cylinder combined valve box, a three-cylinder combined valve box, a four-cylinder combined valve box, a five-cylinder combined valve box, a six-cylinder combined valve box and a seven-cylinder combined valve box. box. The multi-cylinder valve box 32 includes a two-cylinder valve box, a three-cylinder valve box, a four-cylinder valve box, a five-cylinder valve box, a six-cylinder valve box and a seven-cylinder valve box. Each cylinder of the valve box 3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com