Transformer tap switch flexible to install and transformer applying same

A tap changer and transformer technology, applied in the field of transformers, can solve the problems of inability to install, the wiring position is far away, and the length of the coil lead is increased, and achieves the effects of convenient installation and operation, convenient location setting, and simple transmission structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

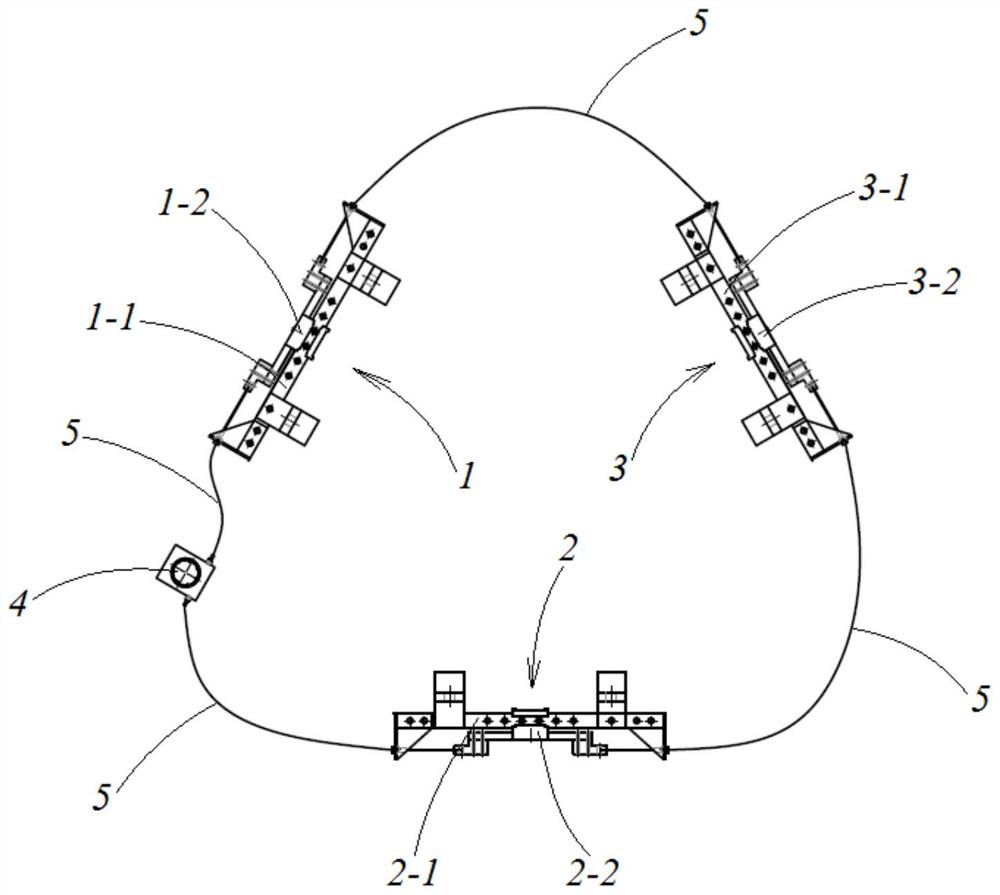

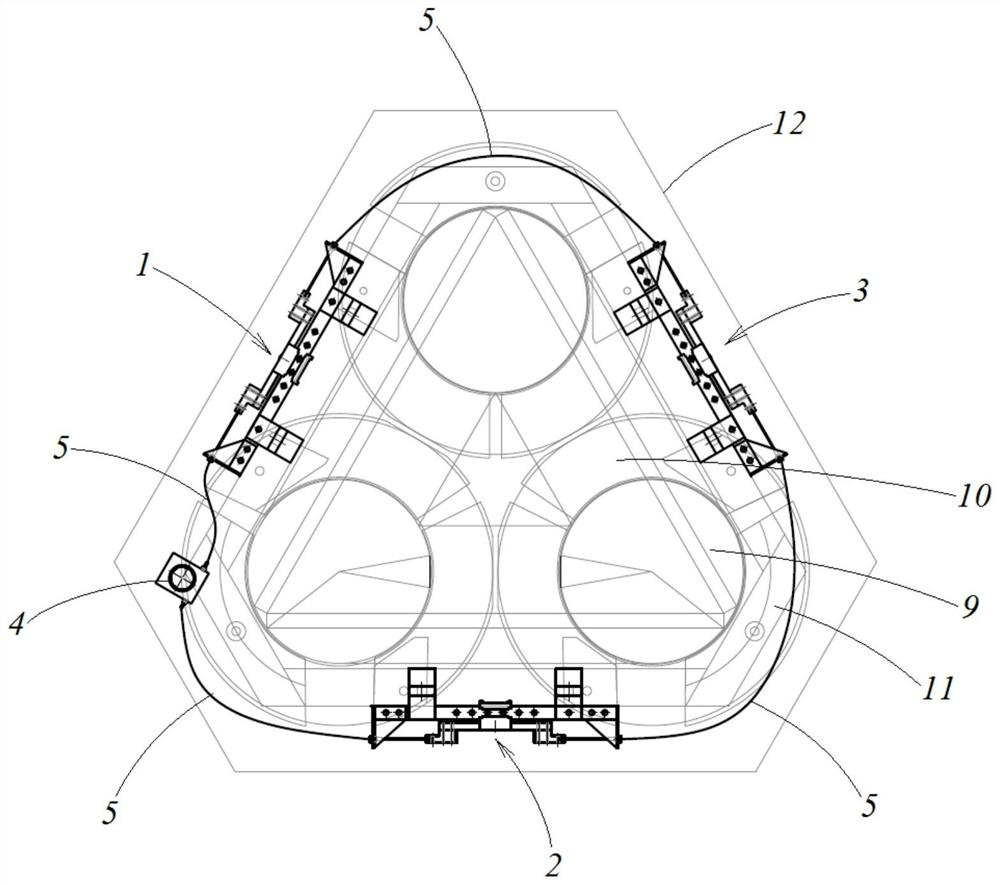

[0047] combine figure 1 As shown, a transformer tap changer with flexible installation in this embodiment includes a first tap mechanism 1, a second tap mechanism 2, a third tap mechanism 3, a switch operating mechanism 4 and a transmission bushing line 5. A tap mechanism 1, a second tap mechanism 2 and a third tap mechanism 3 all include a static contact assembly and a moving contact assembly, and the moving contact assembly and the static contact assembly are relatively sliding and switchable; specifically, the first The tap mechanism 1 includes a first static contact assembly 1-1 and a first movable contact assembly 1-2 that slides relative to the first static contact assembly 1-1, and the second tap mechanism 2 includes a second static contact assembly 1-2. The head assembly 2-1 and the second moving contact assembly 2-2 that is relatively slidingly matched with the second static contact assembly 2-1, and the third switching mechanism 3 includes the third static contact as...

Embodiment 2

[0057] A transformer tap changer with flexible installation and a transformer using it in this embodiment have the same basic structure and working principle as Embodiment 1, except that:

[0058] In this embodiment, the above-mentioned switch operating mechanism 4 is a slide type operating mechanism. Specifically, when the switch operating mechanism 4 is a sliding type operating mechanism, the switch operating mechanism 4 includes a switch base and a sliding body relatively slidably arranged in the switch base. The ends of the flexible wire cores are connected, and the end of the flexible sleeve in the corresponding drive sleeve line 5 is fixedly installed on the switch base. There is a push-pull part on the sliding body, and there is also a gear position mark and a gear position positioning mechanism on the switch base. The flexible core in the transmission sleeve line 5 on one side is driven by the push-pull sliding body, and the transmission sleeve line 5 on the other side...

Embodiment 3

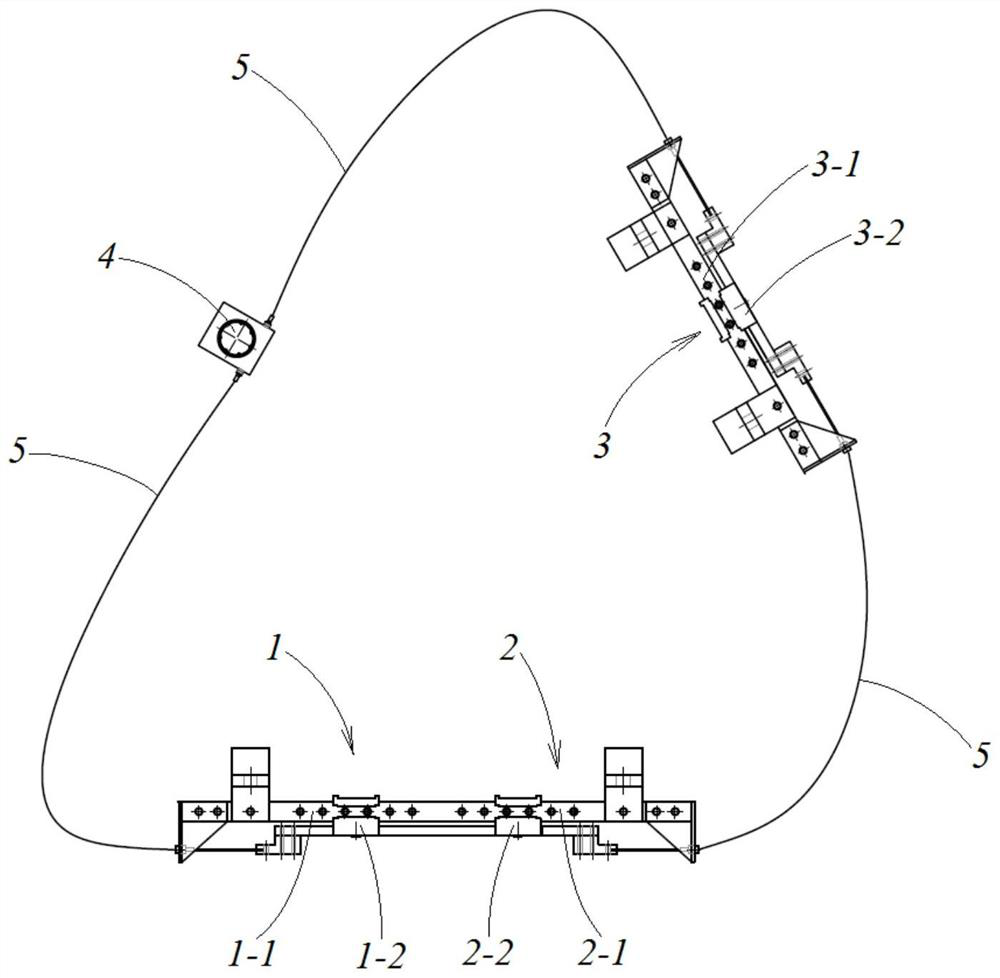

[0060] Such as image 3 and Figure 4 As shown, a flexible transformer tap changer of this embodiment and a transformer using it have the same basic structure and working principle as that of Embodiment 1, except that:

[0061] In this embodiment, any two of the first tap mechanism 1, the second tap mechanism 2, and the third tap mechanism 3 are connected as an integral structure, and pass through the transmission sleeve with the other and the switch operating mechanism 4 end to end. The transmission connection of the pipeline 5 is formed by synchronously controlling the moving contact assembly in the first tap mechanism 1, the second tap mechanism 2 and the third tap mechanism 3 to slide relative to the corresponding static contact assembly through the switch operating mechanism 4. Closed-loop tap-changer in the connection position of moving and static contacts.

[0062] Specific as image 3 , Figure 5 and Figure 6 As shown, the first tap-changing mechanism 1 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com