Electric drill device capable of measuring while drilling

A technology of measurement while drilling and electric drilling, which is applied in the direction of positioning measurement in boring machines/drilling machines, portable mobile devices, drilling/drilling equipment, etc. Disposal, reduced service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

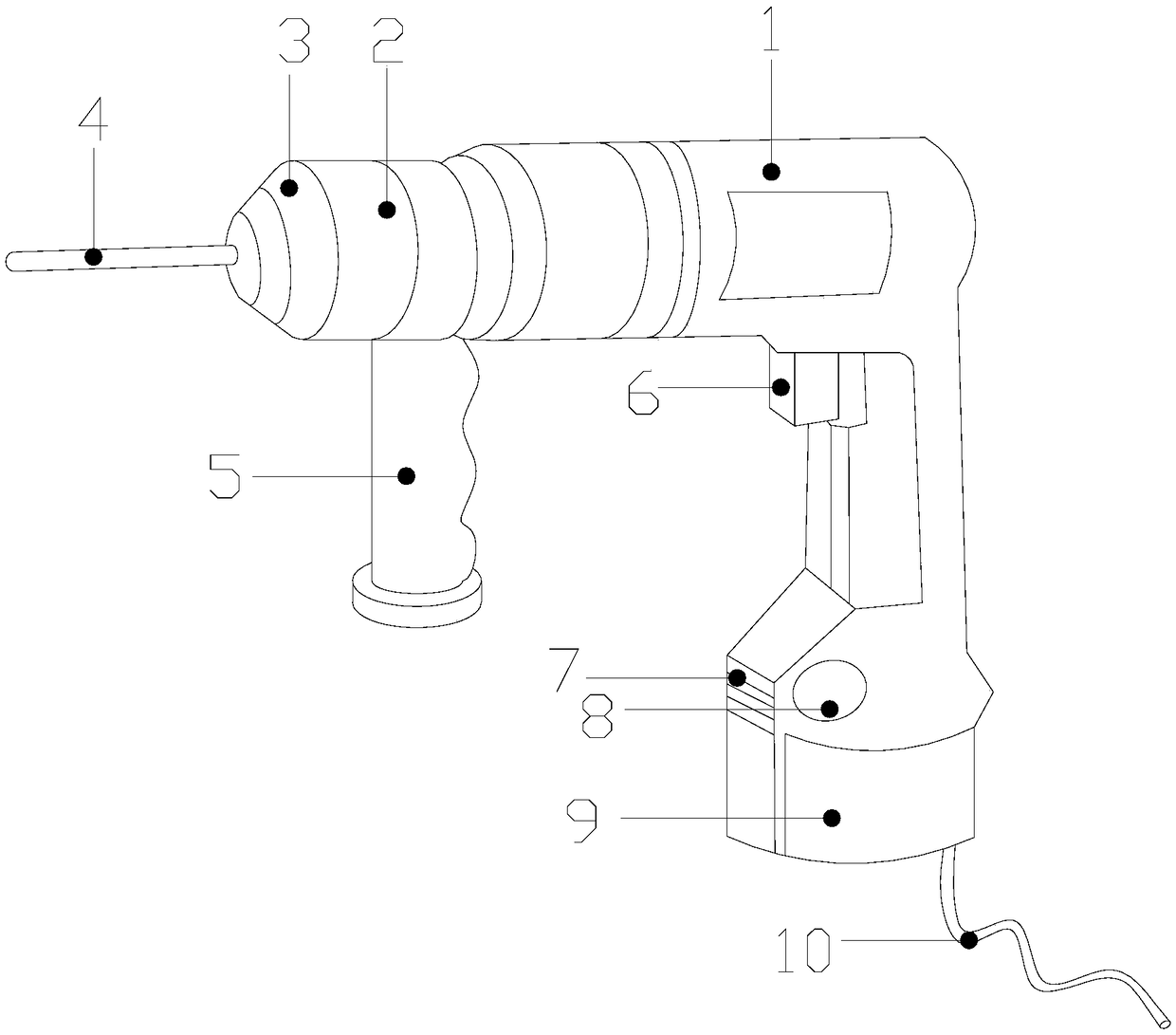

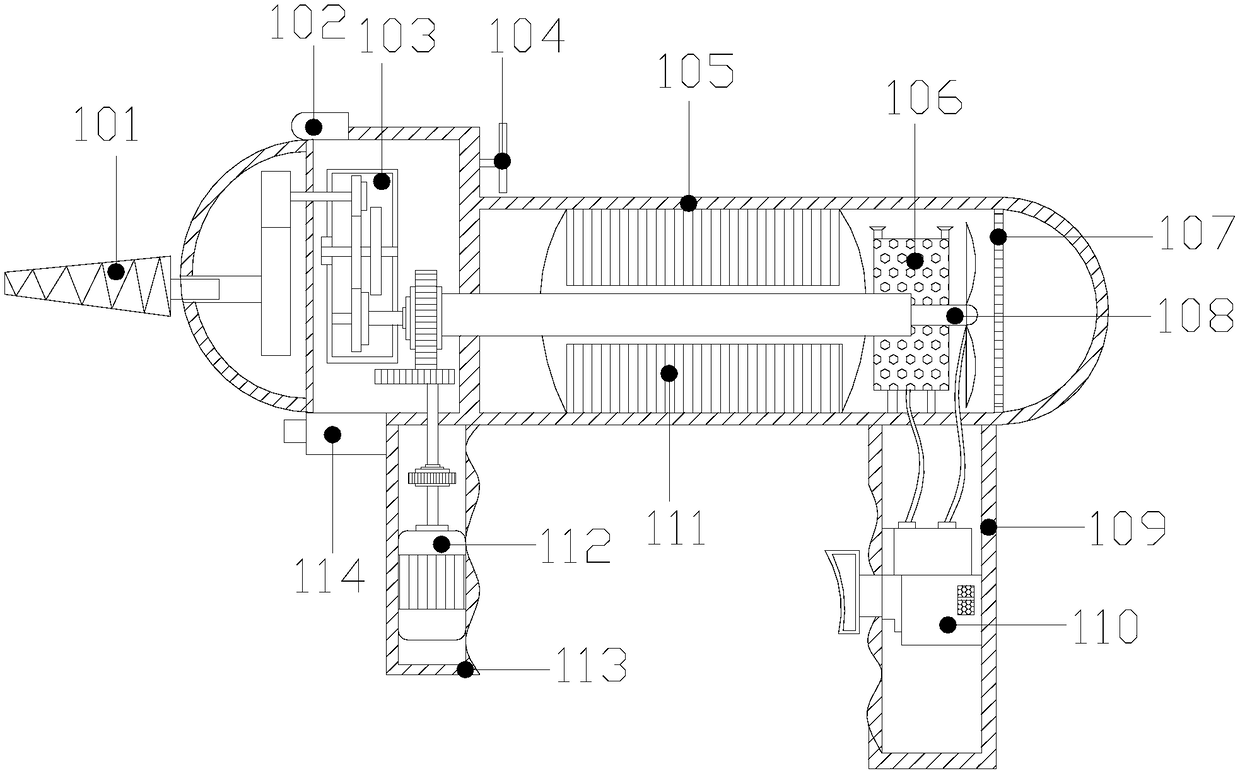

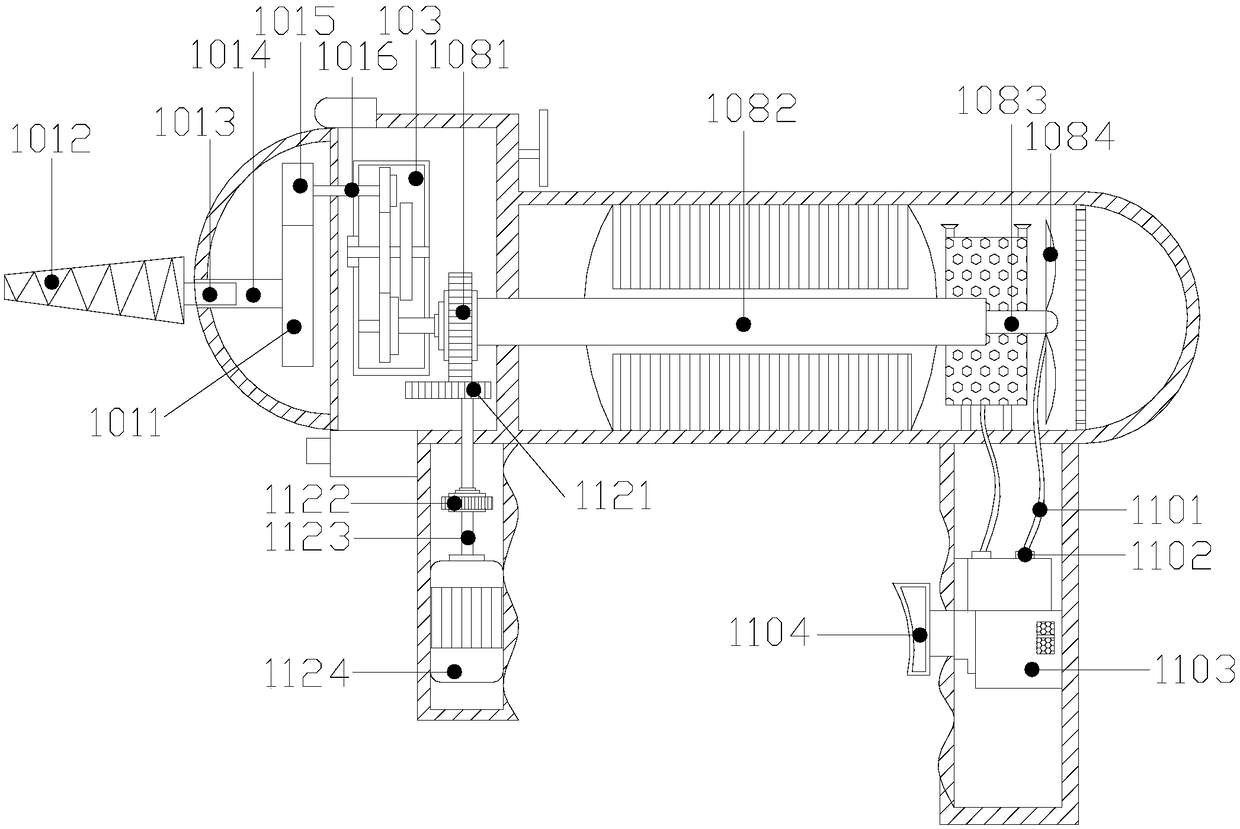

[0022] like Figure 1-Figure 5As shown, the present invention provides a kind of electric drill device of measuring while drilling, and its structure comprises high-efficiency motorized mechanism 1, dust suction pipe 2, dust suction port 3, drill bit 4, handle 5, power switch 6, exhaust port 7, vacuum cleaner 8. Dust box 9, power cord 10, the right side of the dust suction pipe 2 is fixedly welded to the left side of the high-efficiency motorized mechanism 1 and the two are fitted together, and the right side of the dust suction port 3 is fixedly fastened to the dust The left side of the suction pipe 2 and the two are integrally formed structures. The drill bit 4 is welded transversely to the left side of the dust suction port 3 and communicates with each other. The upper end of the handle 5 is fixedly welded to the lower end of the dust suction pipe 2 and passed through the positioning pin. Fixedly connected, the power switch 6 is horizontally embedded in the top left side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com