L-shaped ceramic frame photovoltaic building assembly and L-shaped ceramic frame sintering process

A photovoltaic building and frame technology, applied in photovoltaic modules, photovoltaic power generation, sustainable buildings, etc., can solve the problems of difficult integrated installation of solar cell modules and buildings, inability to achieve integrated connection, and high comprehensive cost of power generation systems. The effect of enhanced market acceptance, increased aesthetics, and large component area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

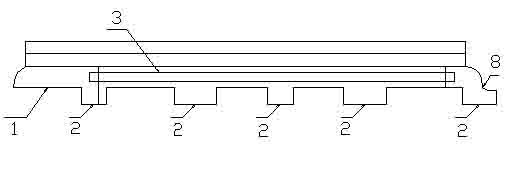

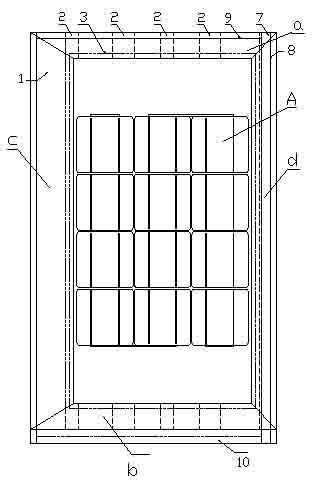

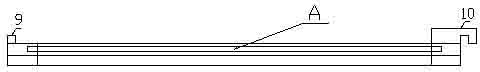

[0056] In order to achieve the purpose of the invention, referring to the four-sided shape of ordinary sintered flat tiles and the process requirements for encapsulating solar cell modules A, the functions of tiles and the frame functions of encapsulating solar cell modules are combined. To this end, the ceramic frame is specially designed, the left and bottom of the four sides are made into an integrated L-shaped frame, and the right and top sides are made into an inverted "L-shaped" frame. The ends of the L-shaped and inverted "L"-shaped frames are inwardly inclined at an angle of 45°, and silicone adhesive is used to make the corners of the two sides closely connected. In the "L"-shaped and inverted "L" The inner side of the ceramic frame is equipped with an axial groove 3 that can be inserted into the packaged photovoltaic module A. Through the joint action of plugging and silica gel adhesive, the photovoltaic module and the ceramic frame are closely connected and play a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com