Antistatic polyformaldehyde resin

A polyoxymethylene resin, antistatic technology, applied in the field of polymer engineering plastics, can solve the problems of self-strength decline, POM violent decomposition, POM poor thermal stability, etc., to achieve good antistatic and electrical conductivity, overall strength improvement, good The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

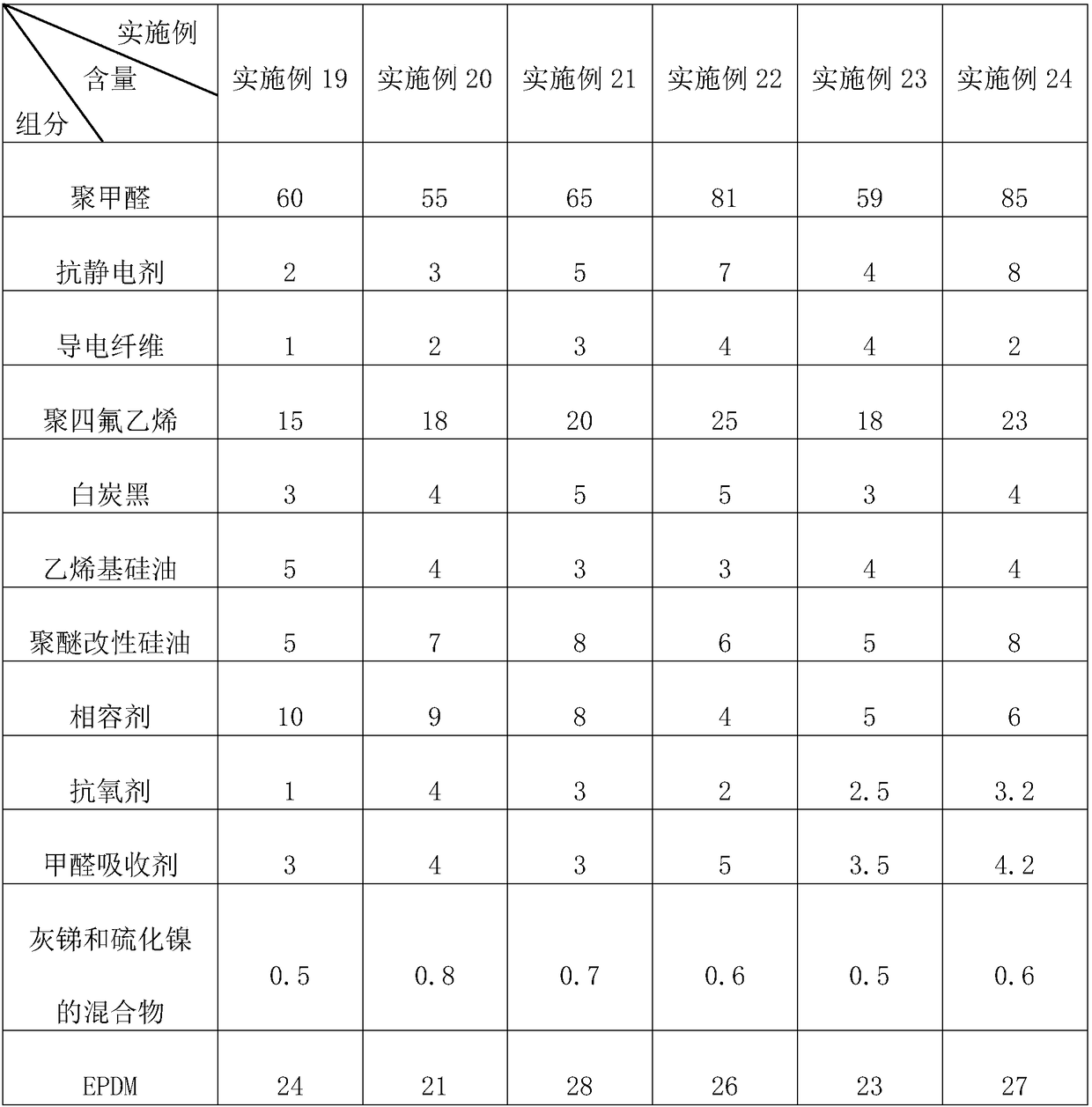

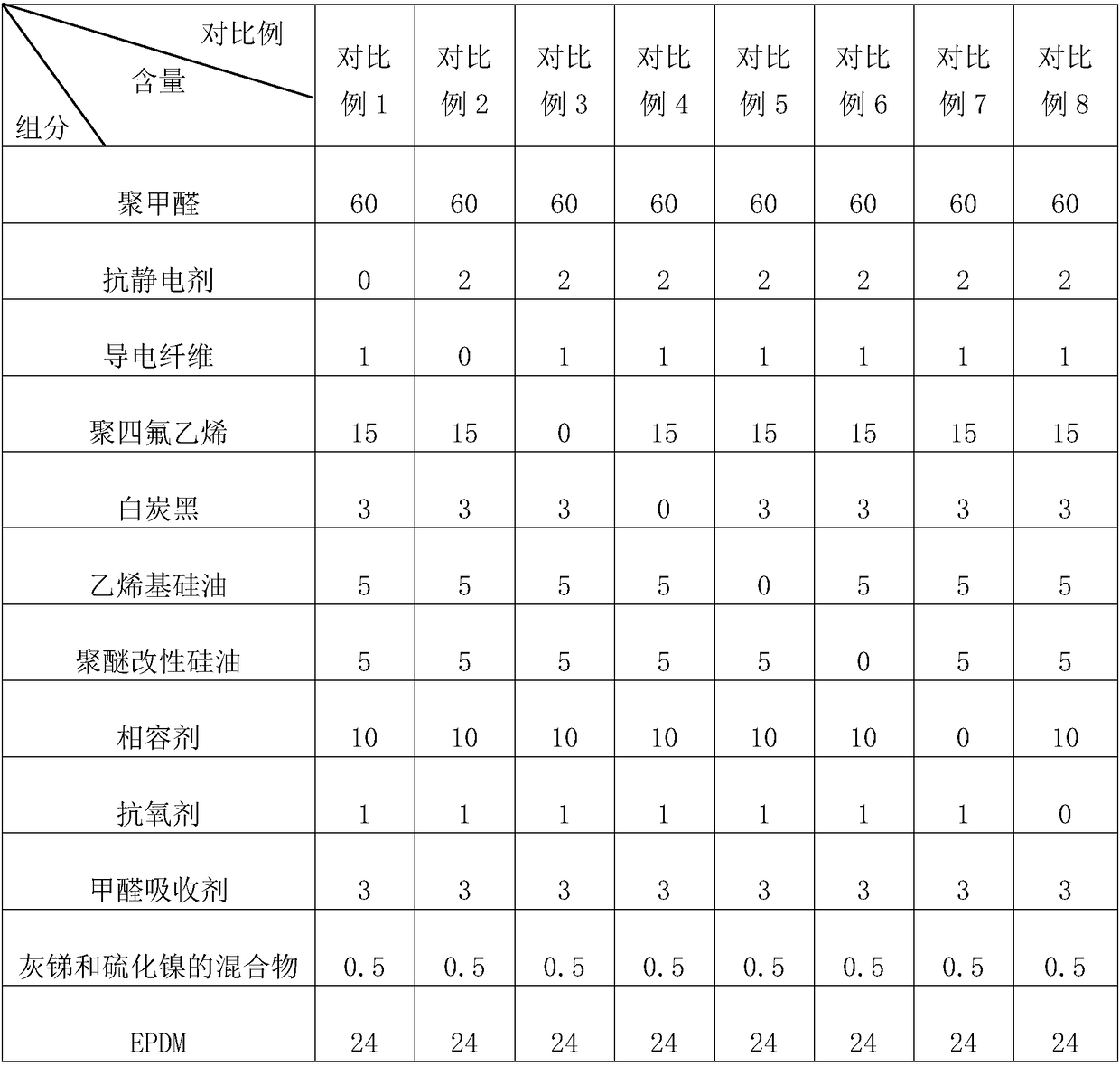

[0023] Example 1-8: An antistatic polyoxymethylene resin, the components included and their corresponding weights are shown in Table 1. The compatibilizer is a polyolefin grafted maleic anhydride copolymer, the antistatic agent is an ethoxylated alkylamine, and the conductive fiber is a carbon fiber.

[0024] Table 1 The components in Examples 1-8 and their corresponding weight tables (kg)

[0025]

Embodiment 9

[0026] Example 9: An antistatic polyoxymethylene resin, which is different from Example 1 in that it also includes 1.5 kg of antioxidant, which is a compound of Inganox245 and Inganox1010.

Embodiment 10

[0027] Example 10: An antistatic polyoxymethylene resin, which is different from Example 1 in that it also includes 3.8 kg of antioxidant, which is a compound of Inganox245 and Inganox1010.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com