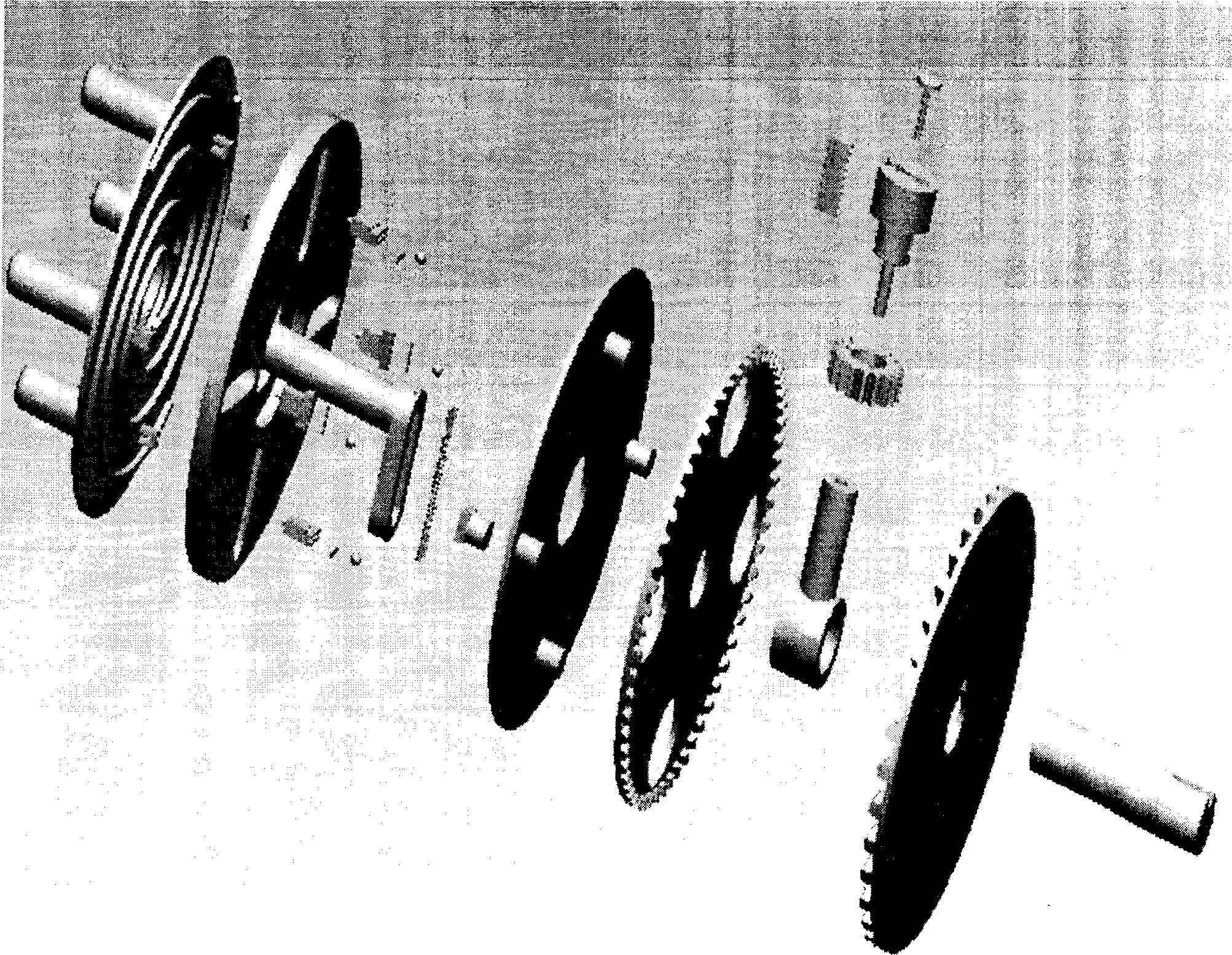

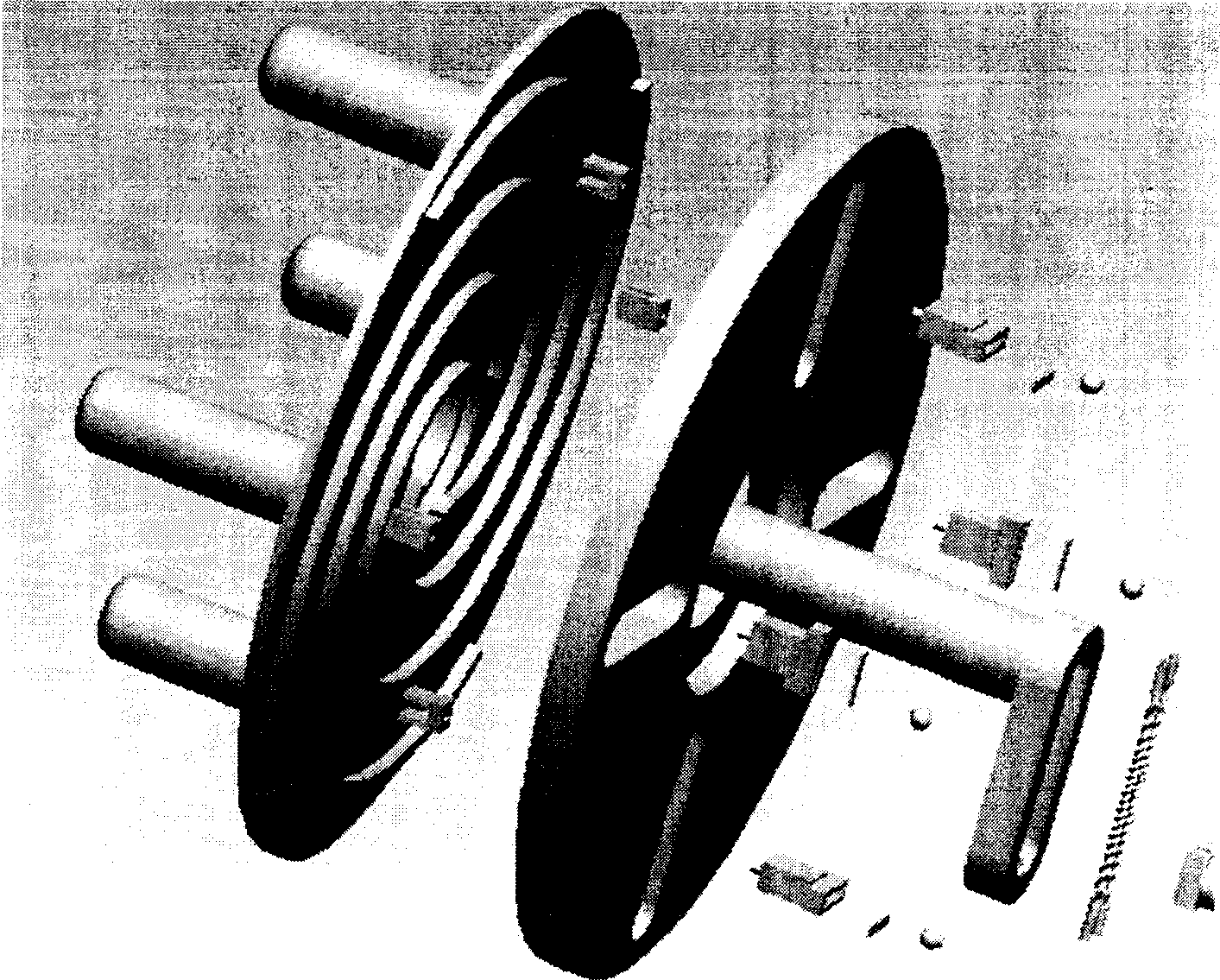

Clutch type stepless speed variator

A technology for variable speed ratios and occasions, applied in belts/chains/gears, mechanical equipment, transmissions, etc., can solve the problem of wide range of air pressure stepless speed change, and achieve avoidance of gearing, good adaptability, and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

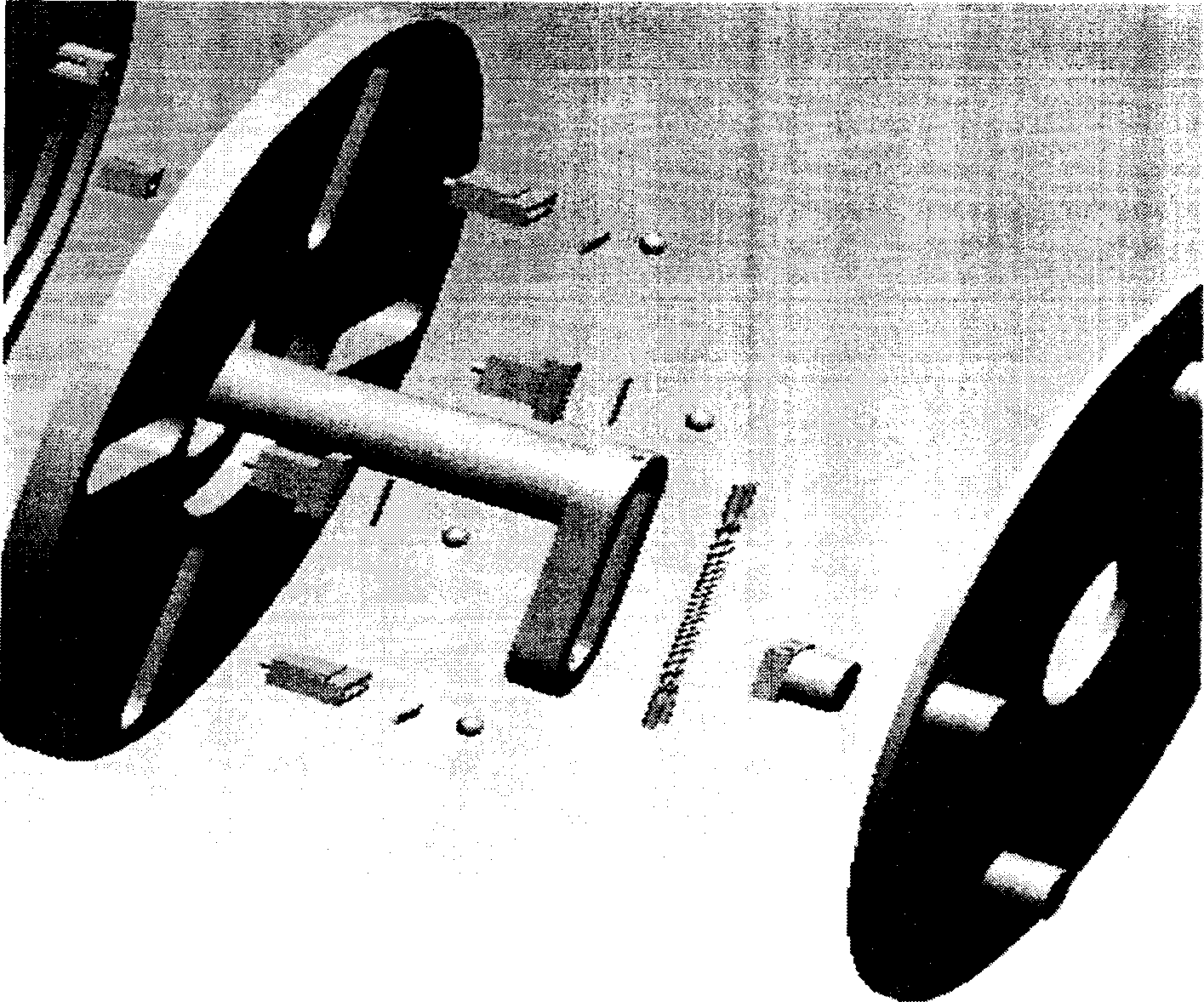

Embodiment Construction

[0083] The mechanism of the present invention only provides the realization method of the key mechanism theory, and further design is needed for the practical specific mechanical structure.

[0084] According to the needs of the speed regulation range in practice, the secondary speed regulation mechanism and the reversing mechanism can be omitted. At this time, if it is necessary to change the steering of the output shaft of the transmission, it can be realized by adjusting the direction of the steel ball bracket. The shifting range of the transmission is also determined by the determined shape of the crankshaft. However, in the initial design, it is still possible to design a suitable crankshaft according to the actual usage.

[0085] When the simple design is adopted, the only thing that needs to be controlled is the rotation of the helical disc. Since the control part is close to the outside of the reducer housing, it is also very convenient to design the control method. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com